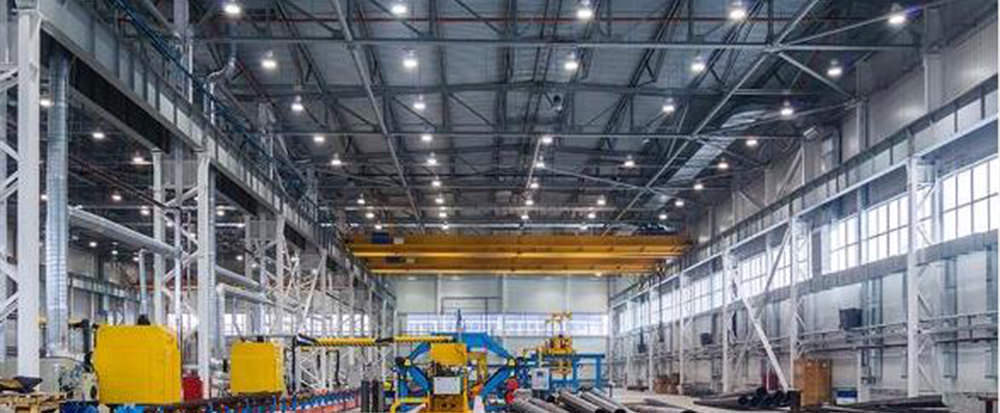

Lighting serves as both a guide and a guardian for the smooth operation in industrial applications. But what happens when those essential lights fail? Faulty industrial lighting can be a significant pain point across various sectors, from manufacturing, leading to costly downtime and safety hazards.

While industrial lights are designed to withstand harsh conditions and provide reliable illumination, various factors can conspire to cause lighting failure. From electrical issues and environmental extremes to mechanical stress and improper configuration, numerous and varied threats could be the cause.

In this blog, we will explore the 12 common causes of industrial lighting failure. By understanding these threats, you can take steps to prevent them and optimize your lighting infrastructure for sustained performance.

- 1. Faulty wiring and connections

- 2. Overloading circuits and fixtures

- 3. Power surges and voltage fluctuation

- 4. Compatibility issues with control systems

- 5. Extreme temperature

- 6. Humidity and moisture

- 7. Accidental impact

- 8. Vibration and shock

- 9. Dust, dirt, and debris accumulation

- 10. Flammable and explosive environments

- 11. Incorrect lighting fixtures for the application

- 12. Inadequate maintenance or replacement schedules

1. Faulty wiring and connections

Sounds strange? Most industrial facilities employ qualified electricians for installation. But faulty wiring and connections are still common causes of lighting failure. Loose connections, the use of substandard materials, improper grounding, and damaged insulation can all contribute to wiring issues.

A loose connection might seem inconsequential, yet it can generate enough heat to degrade surrounding insulation or escalate into a fire. Similarly, corroded wires can impede the flow of electricity, causing inefficiencies and potential hazards.

Regular inspections by qualified electricians, the use of high-quality materials, and adherence to stringent standards are critical in preventing such failures.

2. Overloading circuits and fixtures

Overload occurs when too many fixtures are loaded on a circuit or when fixtures with a higher wattage than the circuit can handle are used. Overloading can cause several hazards. First, it strains the wiring and components within the circuits, leading to overheating. Second, the overload can cause voltage drops, resulting in flickering lights, reduced light output, and shortened lifespans.

To prevent such failures, a meticulous assessment of the electrical load capacity is essential during both the design and expansion phases.

3. Power surges and voltage fluctuation

Power surges and voltage fluctuations are the ‘dirty power’ for industrial lighting. Internally, unbalanced loads, unstable power supply, or faulty electrical connections can send ripples through the power grid, while externally, lightning strikes or utility grid fluctuations can unleash a torrent of electrical energy.

These invisible threats can wreak havoc on lighting fixtures, causing safety issues in industrial facilities. Implementing surge protection devices and voltage regulators can help divert excess voltage away from sensitive lighting components.

Our industrial-grade LED lighting fixtures are equipped with high-quality power supplies and integrated surge protection to effectively counter the adverse effects of erratic power supply. Although it is challenging to completely eliminate power fluctuations, our industrial LED fixtures capable of withstanding such conditions will serve as a reliable safeguard against failure.

Explore Our Industrial Lighting

4. Compatibility issues with control systems

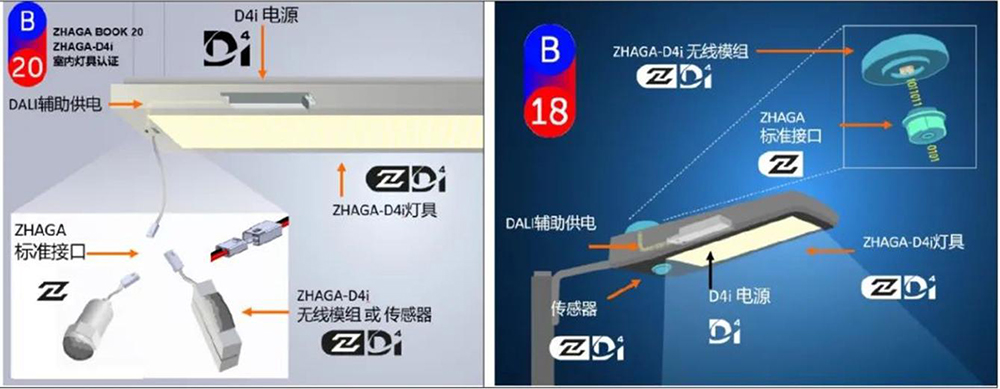

Compatibility issues can arise when lighting fixtures and control systems are not designed to work harmoniously together. Incompatibility may occur due to differences in communication protocols, voltage requirements, or data exchange formats.

Lighting control systems often rely on communication protocols such as DALI, DMX, or Zigbee to communicate with lighting fixtures. If the control system and lighting fixtures use different protocols or if the fixtures do not fully support the required protocol, compatibility issues can arise.

Another aspect to consider is the compatibility between drivers and dimmers. For example, not all 0-10V dimmers can provide a full 0-10V range to drivers. Combining 0-10V dimmers with a 1-10V driver will cause problems such as flickering and stumbling.

Involving experienced professionals during the lighting design and implementation phases can effectively overcome compatibility challenges.

5. Extreme temperature

Whether it's heat or cold, extreme temperatures can pose a significant risk to lighting systems.

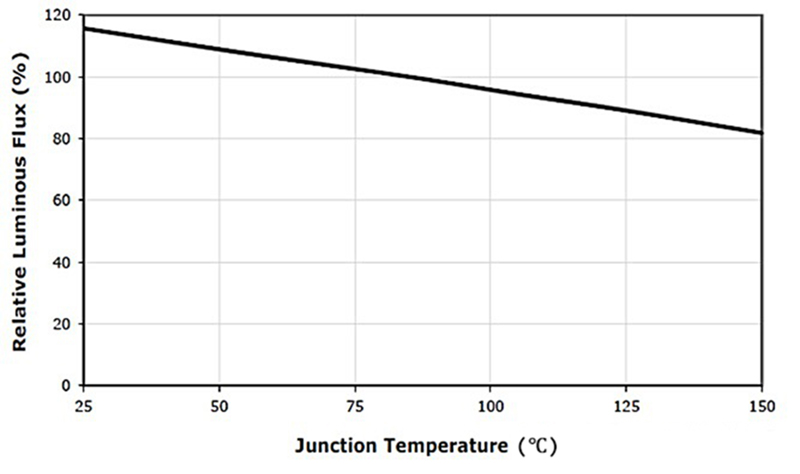

High temperatures can have detrimental effects on lighting fixtures, especially those not designed with effective heat dissipation. When fixtures lack features to dissipate heat effectively, internal components like LEDs and drivers are placed under strain. This strain accelerates degradation, shortening the lifespan of the lights and potentially leading to complete failure.

Cold environments are often moist. These environments can also cause issues such as reduced light output, slower start-up times, corrosion, and increased brittleness of materials.

To mitigate the effects of extreme temperatures, it is crucial to select lighting fixtures specifically designed for these environmental conditions. AGC provides lighting solutions for extreme high temperatures and cold environments. Our HB31 high bay light can maintain stable performance even at 65-70°C. For environments with low temperatures, such as cold storage, our HB06 high bay light can withstand freezing temperatures as low as -30°C without compromising lighting performance.

|

|

6. Humidity and moisture

High humidity and moisture can cause lighting failures in several ways. Firstly, the presence of high humidity and moisture can be particularly detrimental to metal components, causing corrosion, rust, and weakening the structural integrity of lighting fixtures over time. Secondly, when humidity interacts with electrical currents, it can create a conductive path for electricity to flow where it shouldn’t, potentially causing short circuits. Moreover, some facilities, such as offshore oil and gas rigs, paper mills, and chemical plants, are exposed to salty and moist environments. This not only damages the lighting fixtures but also poses a significant safety hazard to the facility and its workers.

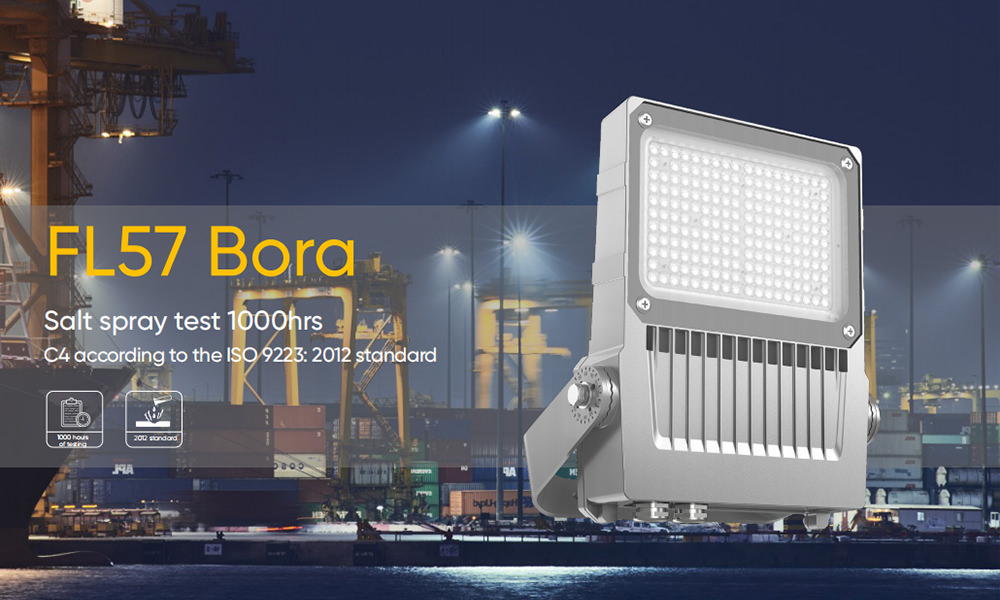

Lighting fixtures featuring high IP (ingress protection) ratings can help prevent water infiltration and protect sensitive electrical components. But for further protection, anti-corrosion lighting fixtures are the better choice. Our FL57 flood light has an IP66 ingress protection rating. It also exhibits excellent anti-corrosion performance with its low copper housing and hot-dip galvanized bracket. Having passed a 1000-hour salt spray test, it provides stable performance in humid and moist environments.

7. Accidental impact

The movement of machinery and materials is constant in bustling industrial environments. The impact of accidents on lighting fixtures can come from forklifts, cranes, or even the handling of goods. These impacts can cause damage to lighting fixtures, including cracks, dents, or shattered lenses, which might expose the internal components to environmental hazards or lead to loose wires.

Selecting fixtures with high IK ratings (normally higher than IK08) and reinforced housing is a crucial step to reduce the risks of accidental impact. Strategically placing lights away from high-traffic areas and potential collision zones can further minimize the risk. Finally, utilizing protective guards or cages around lights provides an extra layer of defense against accidental impact.

8. Vibration and shock

The constant vibrations and sudden shocks generated by heavy machinery, equipment operation, or transportation activities can lead to a host of issues. Prolonged exposure to vibration can cause the loosening of electrical connections, compromising the integrity of wiring terminations and potentially leading to arcing, short circuits, or even complete disconnections. Additionally, vibrations can exacerbate the degradation of components like LED drivers, as the constant motion accelerates wear and tear.

To shield lighting from failure caused by vibration and shock, choose lighting fixtures that have passed vibration tests such as the 3G test. Fixtures that are designed with robust construction and vibration-resistant mountings can further improve their resilience.

9. Dust, dirt, and debris accumulation

In environments where particulate matter is part of daily operations, such as woodworking shops, foundries, or textile mills, lighting fixtures can become coated with a layer of grime. The accumulation of dust, dirt, and debris not only reduces the brightness of the lights but can also contribute to overheating by insulating components and restricting heat dissipation.

For these dusty environments, lighting fixtures with smooth surfaces that are not prone to dust buildup and are easy to clean are the ideal choices. Fixtures with high IP ratings, incorporating effective sealing mechanisms, can help maintain the clarity and brightness of lighting. Regular cleaning and inspection are also critical for preventing dust accumulation.

10. Flammable and explosive environments

In hazardous industrial environments where flammable or explosive substances are present, ensuring the safety of lighting systems becomes paramount. These hazardous areas, such as chemical plants and oil refineries, require specialized lighting solutions.

To address these challenges, fixtures must be robust, sealed, and often equipped with explosion-proof enclosures that contain any potential internal explosion, preventing it from igniting the surrounding atmosphere.

Explosion-proof fixtures are constructed to contain any potential explosion within the fixture itself, preventing the ignition of surrounding flammable substances. However, explosion-proof lights are of various classifications. Therefore, choosing the right explosion-proof light for hazardous locations is important.

Find the Right Explosion-proof Light for Your Facility

11. Incorrect lighting fixtures for the application

Incorrect lighting fixtures for specific industrial applications are a common reason for lighting failure. This mismatch between the fixture’s capabilities and the application’s requirements can be caused by various factors, such as overlooking the operational demands or underestimating the environmental conditions. For instance, a fixture that is not rated for high-temperature environments may quickly degrade when installed near boilers.

A thorough analysis of the application’s needs is key to preventing such failures. Consulting with lighting experts and adhering to industry standards can guide the selection of appropriate fixtures.

12. Inadequate maintenance or replacement schedules

Although industrial lights are built to be tough, a slow decline can also occur without adequate maintenance and replacement schedules. Dust and debris will build up if you fail to clean fixtures regularly. This buildup traps heat, strains components, and shortens the lifespan of the lights. Moreover, without regular inspection and replacement, you cannot identify and replace failing components, which can lead to cascading problems.

To address these issues, you should implement comprehensive preventive maintenance programs tailored to your lighting systems and operational requirements. Proper maintenance and replacement schedules lie in preemptive action, identifying potential problems before they manifest as failures. This involves cleaning fixtures, checking for wear and tear, and replacing components that are nearing the ends of their service life.