- Home

- Products

- Topics

- Applications

From industrial to outdoor lighting, AGC lighting have worked with a number of different customers around the world.View All Case Studies

From industrial to outdoor lighting, AGC lighting have worked with a number of different customers around the world.View All Case Studies - Sustainability

- Blog

- Resources

- Contact

Industrial applications, especially those harsh and hazardous places which face the risk of explosive gases, flammable vapor, dust, and fibers, require explosion proof lights. These applications often have limited entrance and exit points. If an explosion occurs, it might cause severe damage or even injury. Explosion proof lights are typically designed to provide safe lighting solutions to hazardous locations. Our explosion proof lights use powerful LED technology, high quality materials, durable construction, and specialized designs to meet all lighting requirements for hazardous environments. They are ideal for hazardous locations that require efficient and powerful lighting. Featuring die cast aluminum shell and special outdoor powder, our explosion proof lights are resistant to corrosion. The rugged heat sinks and active thermal management make them withstand the high temperature environment. Our LED explosion proof light are available in various classes and divisions ratings. Each of these lighting fixtures can maximize their performance and reliability only in areas where they are best suited. Therefore, make sure you get the right LED explosion lights for your applications.

Explosion proof lights are so-called hazardous location lights. In simple words, explosion-proof lights are the lighting fixtures having a degree of capacity to isolate the fixtures from flammable substances and preventing ignition and sparks. Explosion-proof lights are usually utilized in hazardous locations, which refer to areas where a large amount of volatile or flammable gas, vapor, dust, or fiber is present in the air. Explosion-proof lights can prevent the ignition or sparks escaping from the robust housing. All explosion-roof lights must pass the relevant certifications and tests specified for hazardous locations from official institutions or organizations. Please note that explosion proof lights are designed to prevent lighting fixture from being the cause of an external explosion in explosive environments. It does not mean the lighting fixture can survive an explosion.

All explosion-roof lights must pass the relevant certifications and tests specified to hazardous locations from official institutions or organizations, such as the UL, CSA, etc. In the USA, the explosion proof light requires a certification to UL 844 standard. The three main certifications for electrical equipment in hazardous locations are NEC (North America), ATEX (Europe), and IECEx (Intentional). NEC (Nation Electrical Code) is generally adopted in North America. It classifies hazardous locations based on class/division and the zone. ATEX is a certification that covers the devices and protective systems for proper use in explosive atmospheres. It is standard by European Union to eliminate technical trade barriers. IECEx (IEC System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres) is an international certification aiming to guarantee the highest level of safety of the equipment and the people in explosive atmospheres.

Explosion proof lights are used in both indoor and outdoor hazardous locations. Hazardous locations are places where concentrations of volatile or flammable gas, vapor, dust, or fiber occur. Explosion proof lights mainly used in mining, marine, manufacturing, and industrial applications. Here are some examples of applications of explosion proof lights:

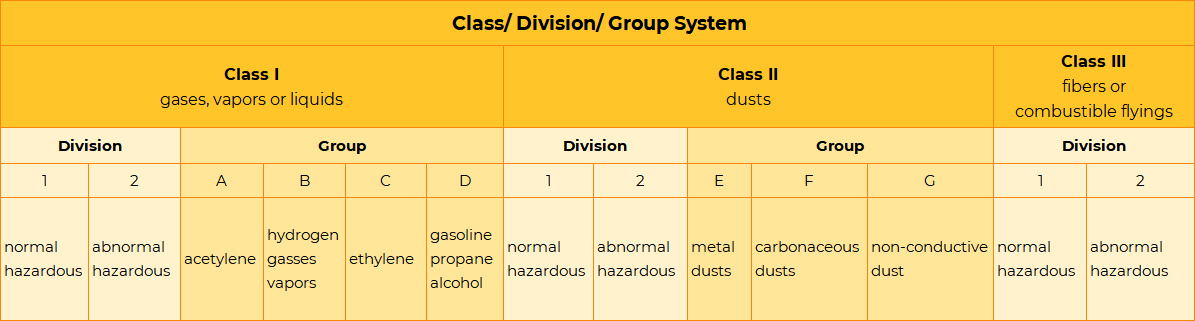

Knowing the classification of hazardous areas is the basic to choose the right explosion-proof lighting for hazardous areas. Hazardous locations are divided by class/division and zone systems.

Class/division classification system is based on the type, condition, and nature of hazardous locations.

Class I: where flammable gases, vapors or liquids are present within the atmosphere.

Class II: where combustible dusts are present within the atmosphere.

Class III: where easily ignitable fibers or combustible flyings are present within the atmosphere.

Division 1: normal hazardous operating conditions.

Division 2: abnormal hazardous operating conditions.

The substances in hazardous locations are split into different Groups within the Class system. Class I includes Group A, B, C, and D, while Class II contains Group E, F, and G.

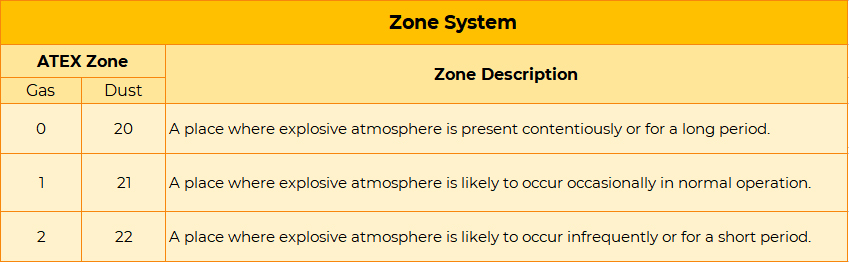

Zone system directly divides the hazardous locations into 6 zones, three zones for gases and the rest for dust substances.

Class 1 Div 1 means areas where the flammable vapors or gases are present at all times under normal operating conditions.

Class 1 Div 2 are areas where flammable vapors or gases are not present under normal operation.

The difference between Class 1 Div 1 and Class 1 Div 2 is the likelihood of the presence of flammable vapors or gases.

At present, AGC provides explosion-proof lights for different hazardous locations. Take Sparkle and HA05 as an example. Both of them are durable and reliable. Sparkle is a LED flood light that is approved for use in: Class I Division 2, Class II Division 1; IEC60079: Zone 2, Zone 21 and 22. HA05 explosion proof light is Class I & II & III, Divisions 1&2 rated. We also keep developing new explosion proof lights to the needs of our customer. For more details of our explosion proof lighting solutions or require custom lighting solutions, please contact us.