In cigarette manufacturing, even a small spark can lead to serious danger. The air is filled with flammable tobacco dust and chemicals, making the work environment highly hazardous. In such conditions, standard lighting can pose a significant risk, which is why explosion-proof lighting is essential.

Our explosion-proof lighting solutions are specifically designed for these challenges. They provide reliable protection, helping maintain smooth and secure operations.

Explosion risks in cigarette manufacturing

Cigarette manufacturing comes with unique risks, especially in areas like tobacco processing, dust collection, material transfer, and packaging. To ensure a safe work environment, strict safety measures are essential.

One major hazard is the fine tobacco dust produced during processing. This dust is highly flammable. First, it has tiny particles with a large surface area, making it easy to ignite. It can also accumulate electrostatic charges, which can lead to sparks. Last, it reacts quickly with oxygen, increasing the risk of fire.

The danger is even greater due to volatile chemicals like adhesives and solvents used in manufacturing. These substances release fumes that, when mixed with an ignition source, can cause fires or explosions.

Another serious risk comes from static electricity. During manufacturing, friction from material movement, pneumatic transport systems, and mechanical handling generate static charges. If not properly controlled, these charges can build up and create sparks strong enough to ignite dust particles in the air, leading to an explosion.

Standards and regulations for cigarette manufacturing lighting

Cigarette manufacturing facilities operate in hazardous environments due to the presence of flammable substances, requiring stringent safety measures for lighting systems. These systems must go beyond basic illumination, serving as critical safety infrastructure that meets and exceeds industrial standards.

One regulation governing cigarette factory lighting comes from the Occupational Safety and Health Administration (OSHA). It mandates explosion-proof equipment, including lighting fixtures, in hazardous locations where combustible materials are present.

Additionally, global and regional standards, such as the National Electrical Code (NEC) in the United States, ATEX directives in Europe, and IECEx international standards, provide further guidance. These regulations require the use of explosion-proof lighting fixtures that undergo rigorous testing and certification to prevent ignition in potentially explosive atmospheres. Cigarette manufacturing facilities must comply with these standards by selecting the appropriate lighting solutions for different hazardous zone classifications.

Beyond electrical safety, other factors such as dust control, ventilation, and material handling must also be addressed to maintain a safe working environment.

Explosion-proof lighting solutions

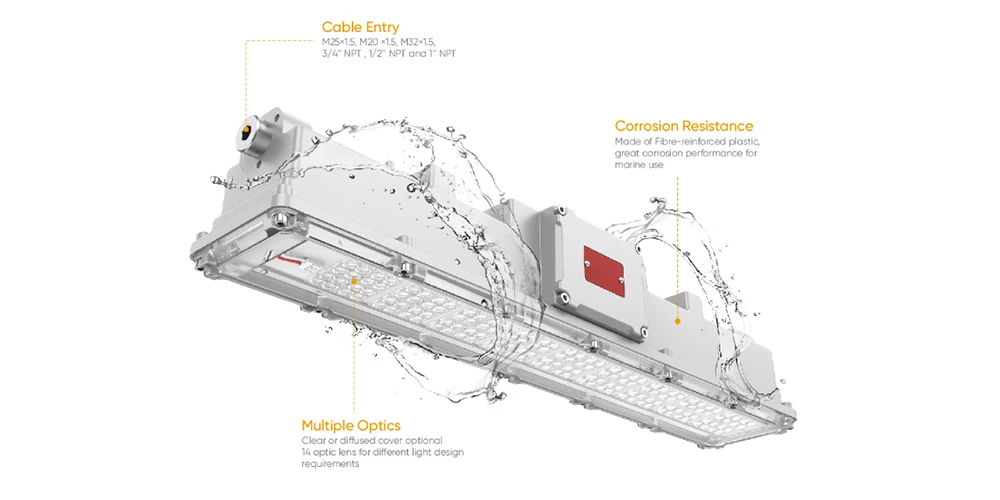

To enhance safety in cigarette factories, we have designed the HA06 explosion-proof lighting fixture, a reliable lighting solution that minimizes risks while maximizing performance.

Unmatched Safety & Compliance

The HA06 is an LED explosion-proof linear light designed for Zone 2 and C1D2 environments, certified by IECEx and CSA, ensuring regulatory compliance and peace of mind.

Durable & Long-Lasting

Constructed from glass-reinforced plastic, it offers excellent resistance to corrosion, current leakage, UV rays, and extreme weather conditions.

Optimal Visibility, Zero Downtime

With multiple optics and installation options, the HA06 provides flexible lighting solutions tailored to your specific needs.

Emergency Backup for Continuous Operation

Keep your facility illuminated during power failures with optional emergency backup (3 hours at 10W or 90 minutes at 20W).

In addition to the HA06, we offer a full range of explosion-proof high bay lights, floodlights, and junction boxes. Need a tailored solution? We provide custom lighting designs to meet your specific requirements.