LED high bay lights are widely used in industrial environments due to their high power, high efficiency, and low energy consumption. Environments of iron and steel manufacturing, pulp and paper mills, and so many industrial plants are harsh and heavy.

Harsh industrial environments such as high temperature, heavy dust, and vibrations, are serious risks of stable lighting performance. However, there are LED high bay lights that are claimed to work well in high-temperature industrial environments. Some of them can withstand up to 70 °C ambient temperature. As we all know, extreme temperatures will cause lumen depreciation and reduced light output. How those LED high bay lights withstand high temperatures in industrial environments?

Effects of high temperature on lighting

In short, high temperatures will damage lighting performance. As known, LEDs generate less heat than conventional light sources during operation. But higher ambient temperature results in higher junction temperature. Furthermore, LED fixtures are made of more than just LEDs. Drivers and other electronic components are significantly sensitive to high temperatures. A long-term high junction temperature leads to the degradation of electronic elements, accelerating lumen depreciation and causing possible failure. As a result, the lifespans and lighting performance of LED fixtures are shortened. High temperature also increases the risk of fire, threatening lives.

General temperature classifications of fixtures are 25 °C, 40 °C, 55 °C, and 65 °C. LED fixtures function well at 25 °C ambient temperature, but LED currents drop sharply when ambient temperature is over 55 °C. In poor dissipation conditions, junction temperature is higher than ambient temperature. The excess high temperature reduces the lighting output. The temperature of the mounted locations often exceeds the floor level. Therefore, to ensure stable lighting performance and safety, the rated temperature of the fixture must be higher than the ambient temperature.

Ways to withstand high-temperature industrial environment

Since high temperatures can cause the decay of lighting performance and there are requirements for LED high bay lights that are able to withstand high temperatures in industrial environments, it is critical to optimum lighting performance in high-temperature industrial environments. But we should note that the junction temperature, not the ambient temperature actually affects the LED fixtures. Therefore, temperature control of fixtures themselves is the leading issue for maintaining lighting performance in high-temperature industrial environments.

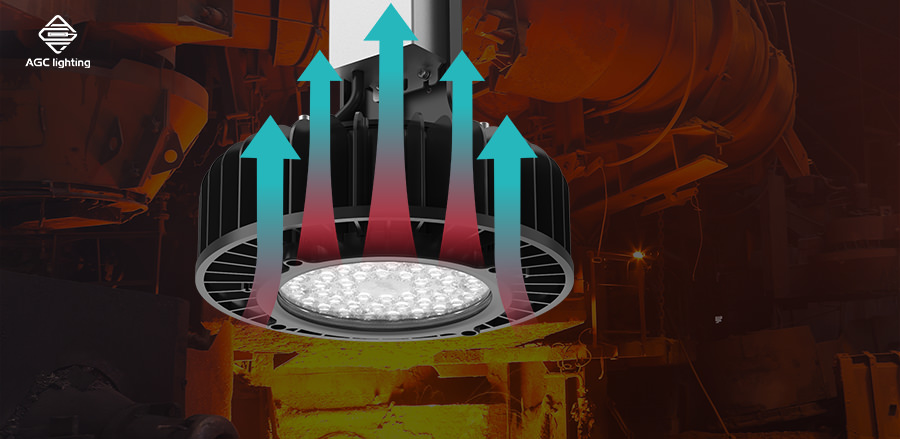

Heat dissipates through conduction, convection, and radiation. To achieve optimized temperature control, one of the key points is to accelerate heat dissipation, while the other is to ensure the heat resistance of the fixture components.

Heat sink

The heat sink is one of the most effective ways to help high bay lights dissipate heat. The heat sink is a structure to conducts the heat away from LEDs to the air, reducing the heat accumulation on junctions and LEDs. To improve heat dissipation efficiency, heat sink is constructed in large surface areas. Fins and channels are the common structures to enlarge surface areas and provide sufficient airflow.

Except for the structures, material with greater thermal conductivity is also beneficial for heat dissipation. Aluminum is a typical heat sink material that is used for industrial environments. The size of the heat sink is determined by the generated heat ambient temperature. A larger heat sink is needed in higher-temperature environments. Robust heat sink reduces lumen depreciation and then extends working life in high-temperature industrial environments. That is the reason why most high bay lights are shaped like UFOs.

Special housing

A housing system is essential for heat resistance and thermal control of high bay lights. It plays an important role in protecting LEDs from high ambient temperatures and allowing higher thermal conductivity. Aluminum is selected as the common housing material due to its excellent performance in heat dissipation and easier manufacturing process.

There are various manufactured processes for aluminum housing. Extrusion, forging, casting, and stamping are the common and cost-effective aluminum manufacturing methods. Higher aluminum purity refers to better thermal conductivity but also higher cost. The surface finish of the housing is a practical way to resist corrosion and increase emissivity. A housing painted with acrylic power cost finishes has greater thermal radiation than unpainted one. Most housing of high bay lights are manufactured with vertical cooling ribs. These vertical ribs work well in preventing dust deposits, reducing obstacles of thermal radiation from LEDs to the air.

Isolate the driver

LED drivers, also called LED power supply, supply and regulate the power to LEDs. Drivers are sensitive to high temperatures. Excessive operating temperature will influence the reliability and shorten the lifespan of the driver. Failures of fixtures are often caused because of the poor performance of drivers. Moreover, drivers generate heat when it is supplying power to LEDs. Drivers cause strong thermal stress to LEDs and result in lumen output reduction.

Actions should be taken to pull the heat away from drivers as well as LEDs to the ambient. Aluminum enclosures are used to improve heat dissipation and facilitate thermal load to the drivers. Isolating driver from luminaires reduces heat accumulation and accelerates heat dissipation, which is ideal for high-temperature applications. Separating the drivers also contributes to relieving heat stress on LEDs.

High-Temperature Lighting Solution

HB45 Sun-chariot are typically designed for high-temperature industrial environments up to 70 °C. A cold forging heat sink provides excellent thermal conductivity and a larger heat dissipation area for optimum heat dissipation. The back cover plate and vertical cooling ribs prevent dust deposits. HB45 is safe to operate in high-temperature industrial environments without compensating powerful lumen output.