- Knowing IP69K

- Knowing the lighting requirements of food processing factory

- Lighting fixtures shall be easy to clean

- Lighting fixtures shall made of safe, non-toxic, and corrosion-resistant material

- Lighting fixtures are designed to prevent dust and debris buildup, pest climbing, and other possible hazards.

- Best IP69K LED lighting solution

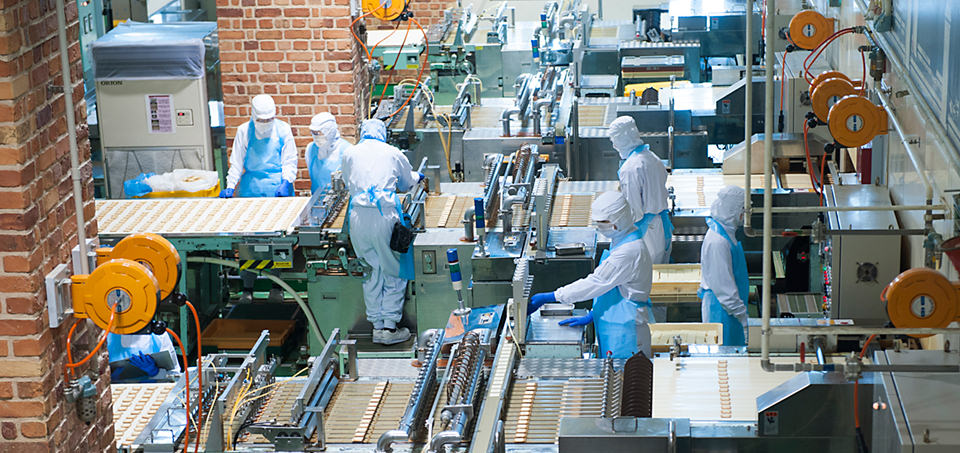

In food processing and food preservation applications, where dust, dirt, and pests are serious problems for food safety. Some food processing areas such as bread and braised food factories, are of high temperature. Operators of food processing applications hate the dust and dirt on lighting fixtures because they must clean and sterilize their processing plants. As known, water and hot temperatures may threat the safety of lighting fixtures. Is there any way to maintain the cleanliness and safety of both food processing plants and lighting fixtures?

The answer is, yes.

Just select the IP69K LED high bay light.

This post will show you the best IP69K LED lighting solution for your food processing applications. Let’s start it.

Knowing IP69K

-

What is IP69K

IP (Ingress Protection) is an internationally recognized scale that indicates the degree of protection of electrical equipment enclosures. “I” represents the level of protection against solid matter, while “P” represents the level of protection against water. IP69K is a degree of protection provided by enclosures (IPX9K), against ingress of dust, high temperature, and high-pressure water. The IP69K rating may be the highest protection for indoor lighting. The high protection rating allows the use of high-pressure water up to 9000kPa and hot water up to 80 ℃ for cleaning LED lighting products. Lighting fixtures with IP69K ranting are ideal for applications where equipment must be carefully sanitized.

-

How to do the test under the standard of IP69K

The test of IP69K is operated according to the standard of ISO20653-2013.

The testing methods are as follows:

The Sample is installed on the turntable.

Speed 5 r/min sprays at 0°,30°,60°,90°

Distance: 150mm

Water flow rate: 15L/min

Water pressure: 9000kPa

Water temperature: 80℃.

Exposure time:30s per position.

Knowing the lighting requirements of food processing factory

Lighting fixtures shall be easy to clean

Dust, dirt, and pests are the common problems of food processing factories. Operators need to clean their applications regularly. If the lighting fixtures are difficult to clean, it will consume extra labor cost, energy, and time to clean the fixtures. Therefore, lighting fixtures for food processing factories should be easy to clean.

Lighting fixtures shall made of safe, non-toxic, and corrosion-resistant material

It is not difficult to understand why non-toxic materials are compulsory for food processing factories. Lighting fixtures without hazardous coating makes them safe for both food and employees in food processing applications. Since lighting fixtures will be cleaned regularly, they should have corrosion resistance. Otherwise, they will damaged by water and the vapor.

Lighting fixtures are designed to prevent dust and debris buildup, pest climbing, and other possible hazards.

The dust and dirt cannot penetrate the case of lighting fixtures, and they will accumulate in the case of lighting fixtures. These accumulated dirt and dust have detrimental effects on food safety. A smooth surface can solve the problem as the dust or water also can not be hoarded on the lamp. But it’s not an easy thing, many products in the market can not meet this requirement.

Best IP69K LED lighting solution

Please see the below test way of LED high bay and LED tri-proof light 20W :

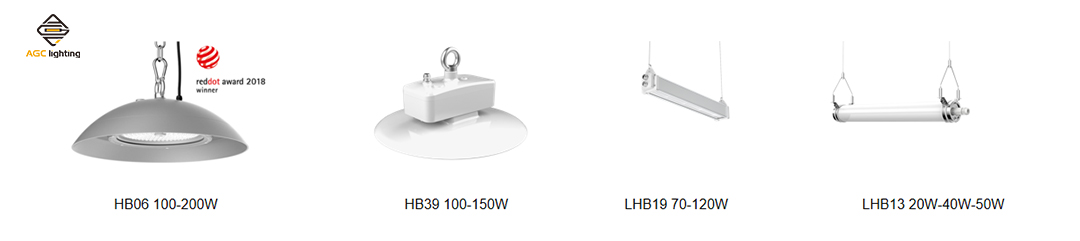

AGC has the below IP69K LED high bay light and LED linear light products to help you solve the dust and dirt problem.

The above lighting fixture is a great fit for the harsh environment of food, beverage, livestock processing, cold storage, manufacturing, and warehousing.

The smooth, seamless, and downward angled aluminum alloy housing ensures zero residue remains after washing down and allows the fixture to drip dry in minutes, to easily conform to food-grade standards.

To learn more about the food processing factory and food preservation lighting application, please contact us.

Related video: