Production lines, like the ones Henry Ford made famous, changed how automotive factories worked in the early 20th century. Instead of one person doing the entire job from start to finish, each worker focused on just one part. This system allowed factories to produce hundreds of cars at once, making them much more efficient.

But keeping workers comfortable while maintaining productivity has always been a challenge. Poor lighting conditions, including glare, can lead to discomfort, mistakes, and lower output.

Think about your current production line: How often do your workers move to avoid glare? How many times has poor lighting led to mistakes in quality control?

- Challenges in Automotive Production Line Lighting

- Auto Production Line Lighting Requirements

- 40W Overhead Work Light: Low Glare, High Performance

- Low glare, High uniformity

- Silicone-free Material to Prevent Contamination

- Adjustable Bracket for Flexible Installation

- High Quality, Easy Maintenance

- CarLite: Glare-Free Lighting Enhances Productivity

Challenges in Automotive Production Line Lighting

Auto production lines face a unique set of lighting challenges. High-quality illumination is essential to meet the complex demands of assembly processes and quality inspection in automotive manufacturing.

Visual Inspection Requirements

One of the primary challenges lies in optimal visibility for inspection tasks. Auto assembly involves multiple surface types - from glossy paint finishes to matte plastics and reflective metals - each requiring precise illumination for quality control. Workers must identify minute defects and ensure proper assembly across these varied surfaces. This makes uniform and consistent lighting important.

Worker Safety and Health

Worker safety and health present another significant concern. The shiny and reflective metal surfaces throughout production lines create significant risks of both direct glare and reflected glare. Extended exposure to glare can lead to eye strain, headaches, and fatigue. All of them can impact both worker well-being and production quality.

Maintenance Costs

Maintenance requirements and high energy costs also challenge the automotive industry. Automotive factories operate for long hours, making any lighting-related disruption costly and resulting in potential production delays.

Auto Production Line Lighting Requirements

In the automotive industry, precision, efficiency, and quality are essential at every step of production. Effective lighting is crucial for achieving these standards, providing the necessary visibility for complex assembly tasks and bodywork. Proper lighting helps workers spot defects like roughness, scratches, and ripples that could impact the vehicle’s finish. Below are some lighting requirements for vehicle manufacturing.

|

Type of task |

Lux-level |

Glare rating |

Uniformity |

Color rendition |

Specific requirements |

|

Press shop - large parts |

300-500 |

25 |

0.6 |

80 |

|

|

Press shop - visual inspection |

500-750 |

22 |

0.6 |

80 |

|

|

Bodywork and assembly - automatic line |

300-500 |

25 |

0.6 |

80 |

|

|

Bodywork and assembly - manual welding |

500-750 |

22 |

0.6 |

80 |

|

|

Painting, spraying chamber, polishing chamber |

750-1000 |

22 |

0.7 |

80 |

|

|

Painting inspection, touchup, and polishing |

1000-1500 |

19 |

0.7 |

90 |

CCT: 4000K -6500K |

|

Detailing - subparts assembly Under chassis assembly - motor and mechanical assembly Final assembly conveyor line |

750-1000 |

22 |

0.7 |

80 |

|

|

Detailing: work with electronics |

750-1000 |

22 |

0.6 |

90 |

CCT: 4000K -6500K |

|

Final inspection |

1000-1500 |

19 |

0.7 |

90 |

|

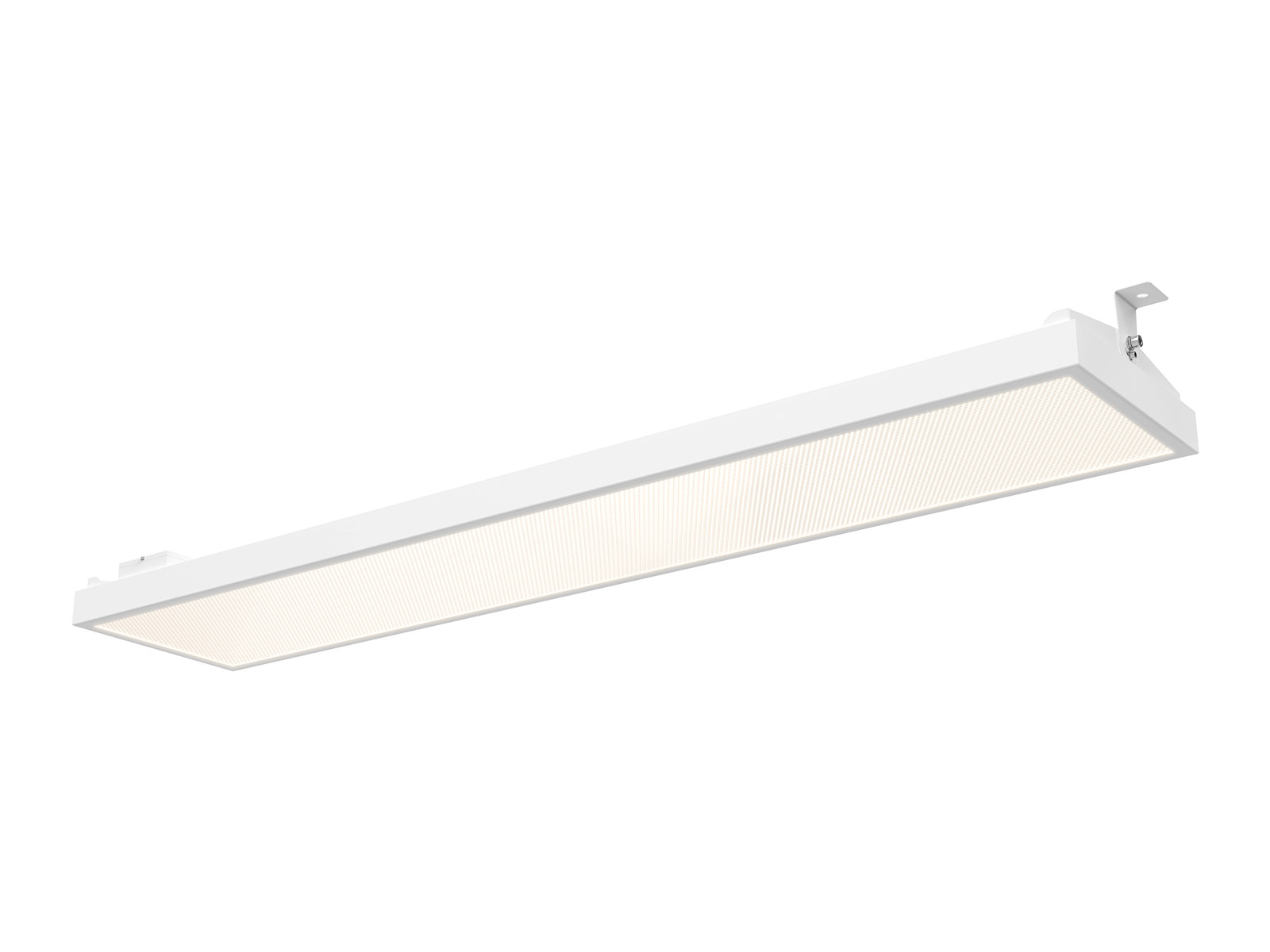

40W Overhead Work Light: Low Glare, High Performance

To address challenges and meet the requirements of the automotive production line, we designed the LHB31 CarLite - a 40W overhead work light. CarLite is built with features like low glare and even light distribution to make sure every workstation has clear, comfortable lighting for long hours of work.

How does our LHB13 CarLite meet the unique lighting needs of automotive workspaces?

Low glare, High uniformity

CarLite features a PMMA diffuser, designed to deliver low-glare, uniform lighting that the automotive industry requires. The large light-emitting surface, paired with an anti-dazzle PMMA diffuser, provides consistent, glare-free illumination with a Unified Glare Rating (UGR) of about 19. The diffuser effectively disperses individual LED light points, reducing subjective glare sensitivity and minimizing unwanted spot reflections on shiny surfaces. This helps create an optimal lighting environment for precision-focused automotive work.

Silicone-free Material to Prevent Contamination

Silicone can adversely affect the surface fluidity of materials, potentially disrupting painting processes and causing visible flaws in the final product. For this reason, the automotive industry often prohibits luminaires containing silicone to minimize contamination risks and ensure high-quality finishes.

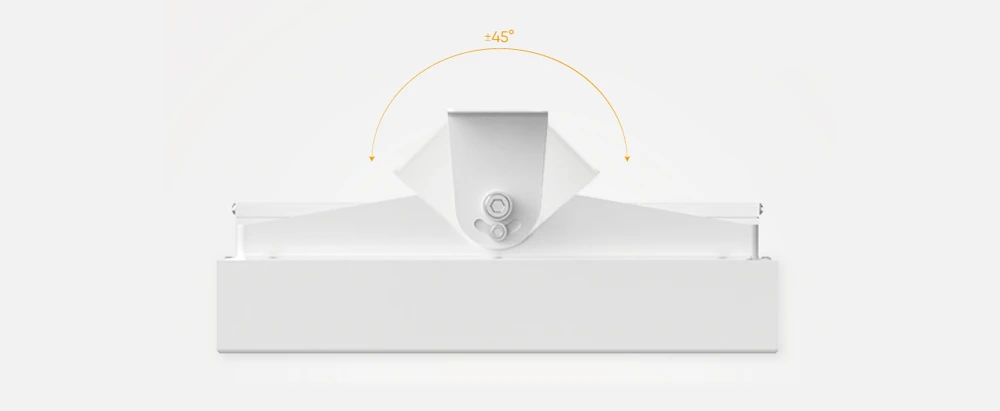

Adjustable Bracket for Flexible Installation

In automotive assembly lines, cars are positioned on platforms about three to four meters wide and workers perform tasks on both sides efficiently. These platforms can move and adjust vertically, providing optimal positioning for each production stage. To ensure comfortable and effective lighting, lighting fixtures should be arranged laterally and parallel to the line.

Our CarLite, with a ±45° adjustable bracket, offers flexibility to suit your specific installation requirements. This setup ensures even light distribution across the workspace, eliminating shadows that could hide defects. It can also reduce unwanted reflections for improved visibility.

High Quality, Easy Maintenance

Replacing defective fixtures and lighting components can be time-consuming and costly in the automotive industry, often leading to unwanted production delays. CarLite is designed for durability with a robust aluminum alloy build and IP50 protection, ensuring long-lasting performance. For easy maintenance, the driver is housed in a separate driver box on the back of the fixture, simplifying access and reducing downtime.

CarLite: Glare-Free Lighting Enhances Productivity

CarLite was installed throughout the automotive production line, positioned both above and along the side of the line. With adjustable brackets, CarLite delivers targeted lighting directly onto the production line, providing ample illumination to support the precise work. The soft, uniform, yet bright light creates a comfortable workspace with minimal glare. Even at a lower mounting height, the light remains easy on the eyes and can be looked at directly.

Our client was very pleased with the results; workers no longer experience the discomfort of glare, enhancing both satisfaction and productivity.