If you are planning to upgrade your lighting system to a smart one, you might be wondering which lighting control socket to use for your fixtures. The sockets add new functions, such as controls and sensors, to LED luminaires and make the lighting smart. When it comes to selecting the right lighting sockets for your project, there are a number a factors to consider. Two of the most commonly used standardized sockets in the lighting industry are NEMA and Zhaga. They define the interfaces and specifications of components in LED-based luminaires. They both aim to make the lighting system more efficient, reliable, and sustainable, but they have different approaches and features that suit different needs.

In this article, we will take a closer look at NEMA and Zhaga standards, compare their key differences, and offer tips on which one is right for your lighting project.

What is NEMA

NEMA stands for the National Electrical Manufacturers Association, a trade association in the United States that sets standards for various types of electrical equipment, including LED-based luminaires. One of the NEMA standards that is relevant for smart lighting projects is ANSI C136.41, which defines the receptacles and controllers that are used to connect and control LED fixtures.

NEMA lighting standards provide a high level of compatibility and interchangeability between different products. This means that products that meet NEMA standards can be easily integrated into existing systems, making it easier for manufacturers and end-users to select and install lighting products that meet their specific needs.

What is Zhaga

Zhaga is a global lighting industry consortium that develops and promotes standards for LED lighting components. The organization was founded in 2010 by a group of major lighting companies and has since grown to include over 350 members from around the world. Zhaga standards allow for greater flexibility and customization in LED lighting design. By using standardized components that can be easily replaced or upgraded, manufacturers and end-users can easily adapt their lighting systems to changing needs. Zhaga is not a certification body, but rather a platform for cooperation and innovation among lighting industry stakeholders. Zhaga members can use the Zhaga logo to indicate compliance with the Zhaga specifications. Zhaga also cooperates with other industry organizations, such as DALI Alliance, to promote common standards and protocols for smart lighting.

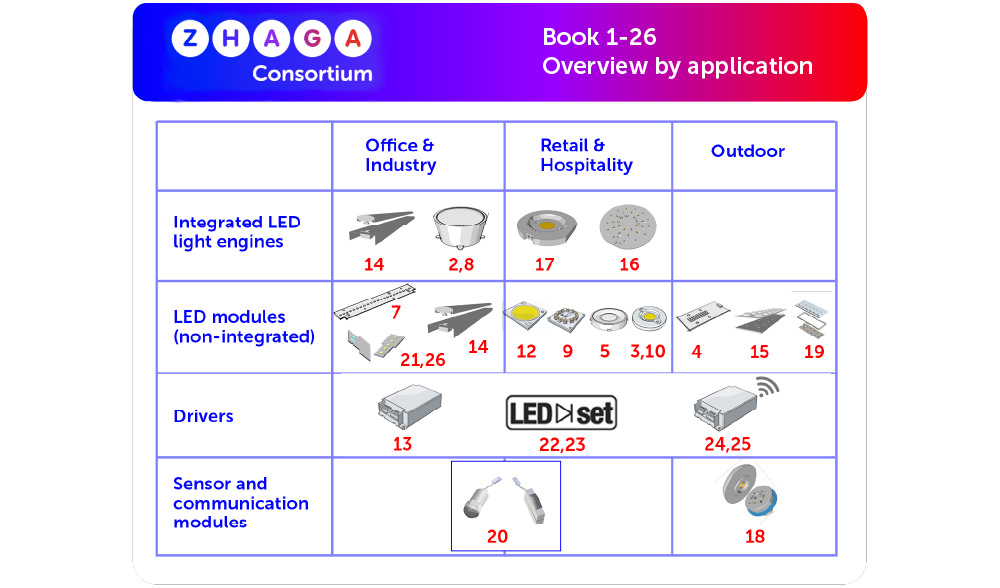

Zhaga has developed several specifications, called books, that cover various aspects of LED luminaries and light engines, such as their mechanical, electrical, thermal, and optical characteristics. Zhaga standard involves LED modules, LED drivers, sensors, and communication modules. The socket standard is Zhaga Book 18, which is combined with the D4i intra-luminaire bus standards.

NEMA (ANSI C136.41) vs Zhaga Book 18, key differences

In this section, we will compare NEMA (ANSI C136.41) and Zhaga Book 18 in terms of their electrical architectures, electrical contacts, dimming support, auxiliary power, interoperability, product lifetime, performance requirements, size, cost, and innovation. We will also highlight their key differences and their advantages and disadvantages.

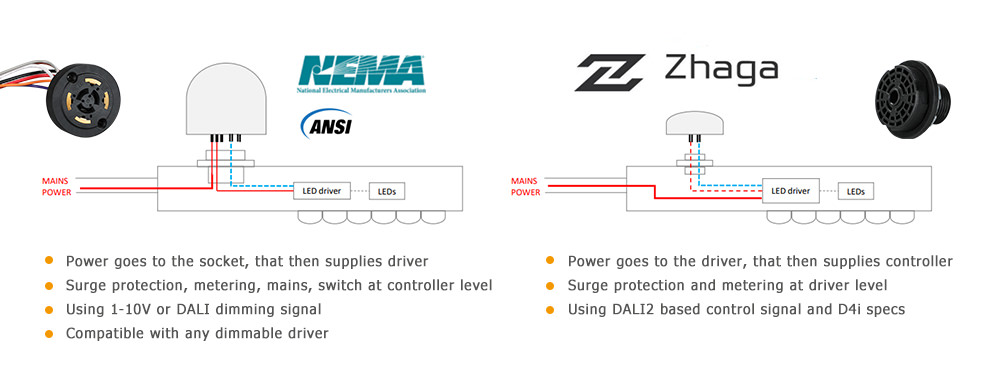

Electrical architectures

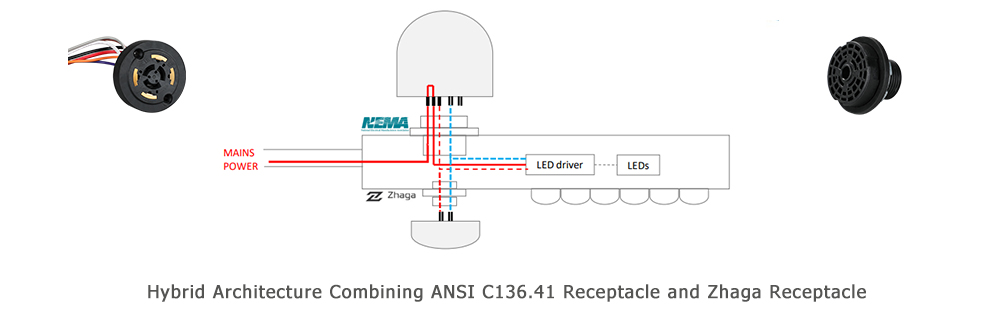

When using a NEMA architecture, the AC mains supply is connected to the receptacle first, which allows the power supply to pass through the node before reaching the luminaire and its driver. The NEMA controller, directly connected to the mains supply, is powered before the luminaire. This approach provides connectivity and a dimming interface for the luminaire control system, as well as surge protection, AC/DC low-voltage power supply conversion, energy metering, and load switching capabilities.

However, in a Zhaga architecture, the AC mains supply connects to the luminaire first, and the Zhaga receptacle only connects to low-voltage auxiliary power supplied by the driver. As a result, the driver in a Zhaga luminaire has more capabilities than a conventional driver, including enhanced surge protection, auxiliary power supply, energy metering, and diagnostics. On the other hand, a Zhaga-certified controller is significantly simplified as it is not connected to the mains.

Performance requirement

Both NEMA and Zhaga standards include performance requirements for lighting products, such as energy efficiency, color accuracy, and durability. However, the specific requirements and testing methods can vary between the two standards.

NEMA standards tend to focus on specific product types and performance metrics, such as lumen output, color rendering index, and fixture life. These requirements are often well-established and widely recognized in the industry, which can make it easier for manufacturers to design and test products that meet those standards.

Zhaga standards, on the other hand, tend to focus on more flexible and adaptable performance requirements, such as mechanical dimensions and electrical characteristics. This allows for greater customization and innovation in LED lighting design, but can also make it more challenging to compare and evaluate different products based on their performance.

Interoperability

One of the main differences between NEMA and Zhaga is their approach to compatibility and interchangeability. NEMA standards focus on defining specific product types and performance requirements, which can make it easier for manufacturers to design and test products that meet those standards. However, this can also lead to less flexibility and interoperability between different products.

On the other hand, Zhaga standards focus on defining standardized interfaces for LED lighting components, such as modules, drivers, and optics. This approach allows for greater flexibility and interchangeability between different products, as long as they meet the same Zhaga interface requirements.

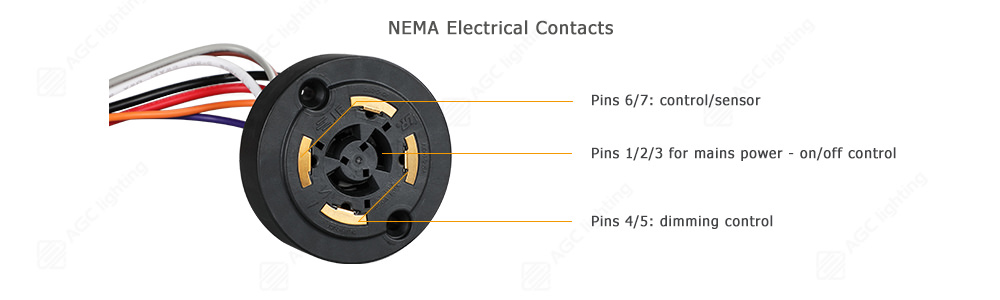

Electrical contacts

NEMA receptacles and controllers use 3-pin, 5-pin, or 7-pin contacts that carry different functions, such as voltage, dimming, and auxiliary power. These contacts include high-voltage lines, which can pose safety risks or require additional protection. NEMA receptacles and controllers are also complex and bulky in design.

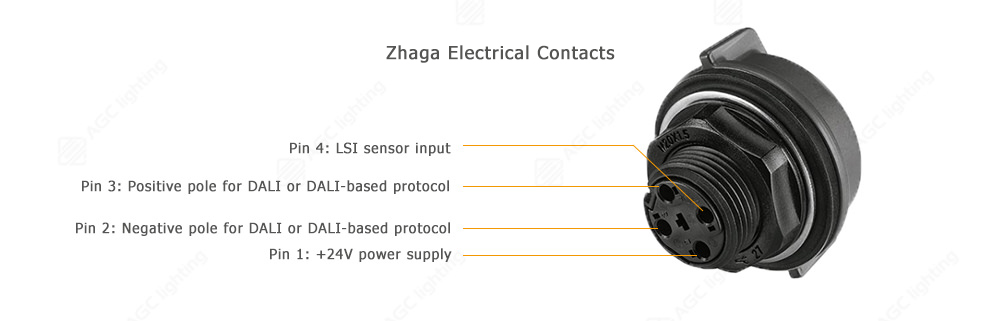

Zhaga sockets and controllers use 4-pin contacts that carry different functions, such as voltage, dimming, and auxiliary power. These contacts do not include high-voltage lines, which makes them safer and simpler to use. Zhaga sockets and controllers are also compact and elegant in design.

Dimming support

NEMA receptacles and controllers support analog (1-10V/0-10V dimming) or DALI communication. However, analog dimming is not very accurate or reliable, and DALI communication requires additional wiring or components. NEMA receptacles and controllers also have limited compatibility with different types of LED drivers or sensors.

Zhaga sockets and controllers support DALI communication by default. DALI communication is more accurate and reliable than analog dimming and does not require additional wiring or components. Zhaga sockets and controllers also have high compatibility with different types of LED drivers or sensors that comply with DALI standards.

Auxiliary power

NEMA receptacles and controllers provide auxiliary power from the LED driver on the 7-pin contact (on the orange wire). However, this feature is not widely supported by LED drivers or sensors and may cause power losses or instability. NEMA receptacles and controllers also have limited options for auxiliary power voltage or current.

Zhaga sockets and controllers provide auxiliary power from the LED driver on pin 1 by default. This feature is widely supported by LED drivers or sensors that comply with Zhaga or DALI standards and ensures power efficiency and stability. Zhaga sockets and controllers also have flexible options for auxiliary power voltage or current.

Product lifetime

NEMA controllers are designed to be connected directly to the AC power supply (115V/230V) from the power grid. Inside the NEMA controller, the AC voltage is converted to DC voltage to power its internal electronics, and the AC power is then passed on to the LED luminaire. However, the AC components in the NEMA controller are prone to failure over time due to voltage fluctuations and surges on the power grid. Additionally, the mandatory AC/DC conversion requires a set of electronic components that are also prone to failure over time. This results in NEMA controllers having a shorter design lifetime compared to Zhaga controllers.

Compared to NEMA controllers, Zhaga controllers have significantly better lifetime and reliability because they operate on a DC input and do not require AC/DC conversion. In contrast, NEMA devices require both the driver and the controller to undergo AC/DC conversion, which increases the number of components and reduces reliability.

Size

NEMA controllers typically require more components than Zhaga controllers, which often results in a larger physical size for NEMA controllers.

Zhaga controllers are typically much smaller than conventional NEMA controllers, often only half to one-third the size. This is primarily due to the fact that Zhaga controllers require significantly fewer components, such as the elimination of the need for AC/DC conversion and power-metering circuits.

Cost

NEMA controllers typically have more components, which can make them more expensive than other options. When installing a connected-ready luminaire with a NEMA socket but no node, it's necessary to use an electro-mechanical shorting cap. Without it, the NEMA luminaire will not function properly. However, this additional component adds extra costs to the system.

Zhaga controllers are typically lower cost components as they don't require AC/DC conversion or a metering circuit. In contrast, a Zhaga luminaire may be more expensive as it requires a driver with enhanced capabilities. When installing a connected-ready luminaire with a Zhaga socket but no node, a simple mechanical cap is enough to protect the socket. The cap can be easily removed once a Zhaga-D4i controller is mounted on the street light.

Innovation

NEMA receptacles and controllers have low innovation potential for smart lighting applications. They are based on an old conventional standard that has not evolved much over time. They also have limited features or functions that do not support advanced capabilities or services for smart lighting.

Zhaga sockets and controllers have high innovation potential for smart lighting. They are based on a modern industry standard that is constantly evolving and improving over time. They also have rich features or functions that support advanced capabilities or services for smart lighting applications, such as data collection, asset management, or dynamic control.

Download the table about the comparison between NEMA and Zhaga.

Download the table about the comparison between NEMA and Zhaga.

NEMA vs Zhaga, which one is right for your lighting project

When it comes to choosing the right lighting standard for your project, there is no one-size-fits-all answer. The answer depends on several factors, such as your project size, scope, budget, expectations, etc.

Here are some questions that can help you decide which standard is more suitable for your lighting projects:

- What is the size and scope of your project? How complex or simple is your project design?

- What is your budget and timeline? How much can you afford to spend on your project?

- What are your expectations and requirements for performance and quality? How important are factors such as energy efficiency, reliability, durability, and safety for your projects?

- What are your preferences for design and aesthetics?

Depending on your answers to these questions, you may find that NEMA or Zhaga is more suitable for your project. Here are some examples:

- If you have a large or complex project with a high budget and a long timeline, you may prefer Zhaga, as it offers more flexibility and scalability for future upgrades or expansions.

- If you have high expectations and requirements for performance and quality, you may prefer Zhaga, as it provides more accuracy and reliability for dimming and communication, as well as more efficiency and stability for auxiliary power.

- If you have strong preferences and values for design and aesthetics, you may prefer Zhaga, as it has a more compact and elegant design that can enhance the appearance and functionality of your project.

Of course, these are not hard-and-fast rules but rather general guidelines that can help you make an informed decision. Ultimately, the choice between NEMA and Zhaga depends on your personal judgment and evaluation of the pros and cons of each standard.

Currently, the industry is introducing new equipment that can replace NEMA sockets with receptacles that support Zhaga standard controllers. This equipment works like an adapter, converting the NEMA interface into a Zhaga interface. It comes with a built-in AC-DC switching power supply, providing a 24VDC power output with a maximum power of 5W. The cost of this equipment is much lower than replacing a dimming driver with an auxiliary voltage output. This solution is ideal for situations where the customer's driver doesn't support the Zhaga controller with an auxiliary voltage output. Additionally, NEMA has also announced plans to introduce similar standards.

AGC provides both NEMA and Zhaga options. If you want to know more information about NEMA or Zhaga, or some case studies of lighting projects that use either NEMA or Zhaga, please feel free to contact us.