With the development of LED technology decades, LED lighting has entered a relatively mature stage. The segmentation of LED lights is becoming more and more refined. universal product have been unable to satisfy the market demand nowadays. since it was found that in the actual application, the same lighting product in warm season places where lighting effect is very good but when applied to cold season places , the lighting effects are not so good. Such an obvious defect is not acceptable to the people. Currently ,the application of lighting product is put to the test by the actual market demand . it is time for lighting supplier to accelerating the upgrading of products and refine the supply .This post will analyze some key factors affecting LED lights in cold environment, find out the corresponding solutions, and finally meet the actual market demand of LED light .

The advantages of led lights in cold environment

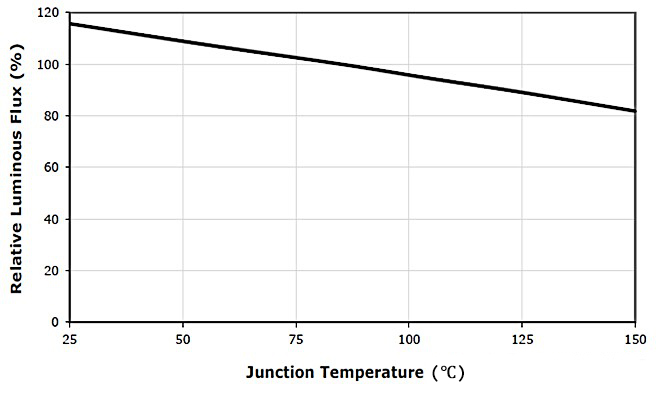

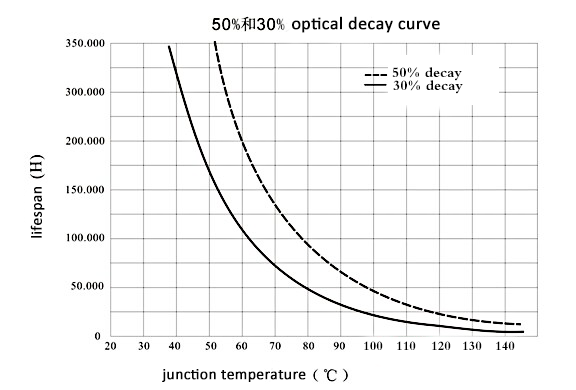

Compared with the original incandescent, fluorescent and HID, the electronic devices of LED lights work much better at normal temperatures. this could even say its optical property perform more excellent at low temperature than that at normal temperature. because it is closely related to the temperature characteristics of LED devices . graph 1shows the temperature and relative luminous flux curve of a high power led lights . it can be seen that with the decrease of junction temperature , the luminous flux of luminaires will increase relatively . according to the heat dissipation law of lights ,the junction temperature is closely related to the ambient temperature ,the lower ambient temperature , the lower junction temperature . in addition , according to the graph 2 , we can see that the reduction of the junction temperature can also reduce the light decay process of LED light sources , lengthen the lifespan of lights , which is also the characteristic of most electronic components .

the issues and measures of led street lights in cold environment

although there are many advantages for led components in the cold environment, there is still some things can not be ignored . in addition to the led component , there are also other factors affecting the lighting output of led lights , such as driving power , the material of housing , the fog caused by weather, strong ultraviolet and other comprehensive weather factors. these factors all bring challenges and problems to application of most outdoor led lights such as led street light . Only after these constraints are made clear and corresponding solutions are worked out can we fully make the most of the advantage of led lights and let them shine in cold environment as well .

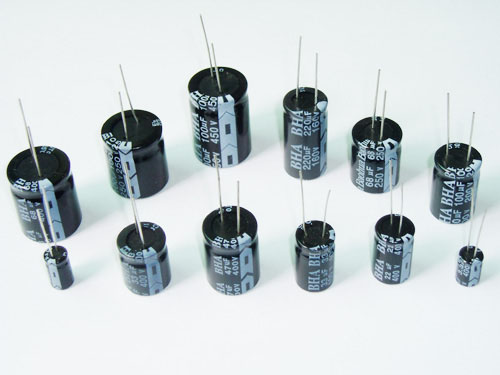

1.the startup problem of drive power in low temperature

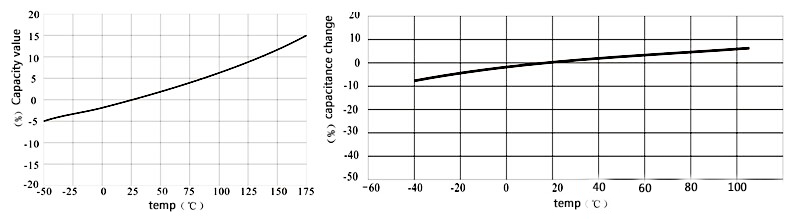

the startup of driving power at low temperature is a difficult problem . the main reason is that most of the existing driving powers are inseparable from the wide application of electrolytic capacitors (as shown in graph 3). as a matter of fact , the electrolyte activity of the electrolytic capacitor significantly decrease and the capacitance of the capacitor greatly attenuate in minus 25 such a low temperature environment , resulting in the circuit not working properly . now there are two solution to this problem; One is to use high-quality capacitors with wider range of operating temperatures,which of cause adds to the cost; The second is the use of driving power without electrolytic capacitor circuit design, including the use of ceramic laminated capacitor , linear drive and other driving schemes.

graph 4 show the changing curve of electrolytic capacitor of two materials . the left one is tantalum , the right one is aluminum. these two curves also show the relationship of temperature and electrolytic capacitor .

moreover, at the low temperature , the voltage resistance of ordinary electronic devices such as MOS tube will also decrease , which will lead to an adverse effect on the overall reliability of circuit and require special attention.

2.the reliability of plastic material under high and low temperature impact

According to the experiments of researchers in some research institutions at home and abroad , it has been confirmed that the toughness of many common plastic and rubber materials become worse and their brittleness increase at a low temperature below minus 15 ℃. for outdoor led lights such as led street light , led sports light , led area light and led flood light etc , their visors, optical lenses , seals and other components are all likely to use plastic material. If it is impossible to avoid the use of these fragile materials,the cryogenic mechanical properties of these materials must be carefully considered, especially the load-bearing parts. this can avoid the rupture of LED lights because of wind and accidental collision at low temperature environment, which may lead to the occurrence of accidents.

In addition , led lights often adopt the matching structure of plastic parts and metal . since there is a significant difference in the coefficient of expansion between these two materials when temperature varies greatly . ans this is also one of the main reasons why the waterproof of outdoor led light failures.for example , the expansion coefficient of commonly used plastic materials are about 5 times of commonly used aluminum . due to this difference, structural components are often prone to gaps, even lead to plastic material cracking. that is why poor waterproof property and product problem exist.

Some areas are in cold season for a long time. the temperature of led lights are often lower than -20℃ before they are turned on in the afternoon.when the luminaires are lit up . the heat generated by the lights help to makes the temperature rise to more than 30℃~40℃. basically ,those luminaires must experience at least a cycle of high and low temperature impact every day . In such an environment, if the structural design of led lights and the matching of different materials are not handled well, it is easy to lead to the cracking and waterproof failure of luminaires mentioned above.

3. the fog penetration ability of led lights

In many places, the fog will gradually increase as the coming of winter. In places with foggy weather, the selection and use of led lights not only need to consider the CRI level, but also the penetration ability of light to fog and the harmony between light and the surrounding environment all should be taken into account.

4.the aging problem of outdoor led lights due to ultraviolet .

In the field performance test of LED outdoor lights with similar driving power in the same place and period, it was found that the lighting decay of LED tunnel lights with 24-hour operation was much smaller than that of street lights with more than 10 hours of operation. After analysis, it was believed that the most likely reason was the aging of related parts caused by ultraviolet light during the day.

The selection of outdoor led lights requires careful consideration and careful analysis of product performance. Choose the satisfied lamp, you will be amazed at the reliability of their performance for a long time to come, including their high quality, high efficiency and durability,. Choose wrong lights, you will receive more customer complaints in the near future.

More cost-effective and high quality outdoor led lights visit https://www.agcled.com/solutions/outdoor/?from=home?from=sopl.