The LED chips are easily damaged in some areas, especially the outdoor flood lights installed at a higher height above 15m when in some areas with bad weather.

There are four main reasons: weather environment, residual voltage, insulation dielectric layer of PCB, LED chips electrostatic discharge.

Weather environment

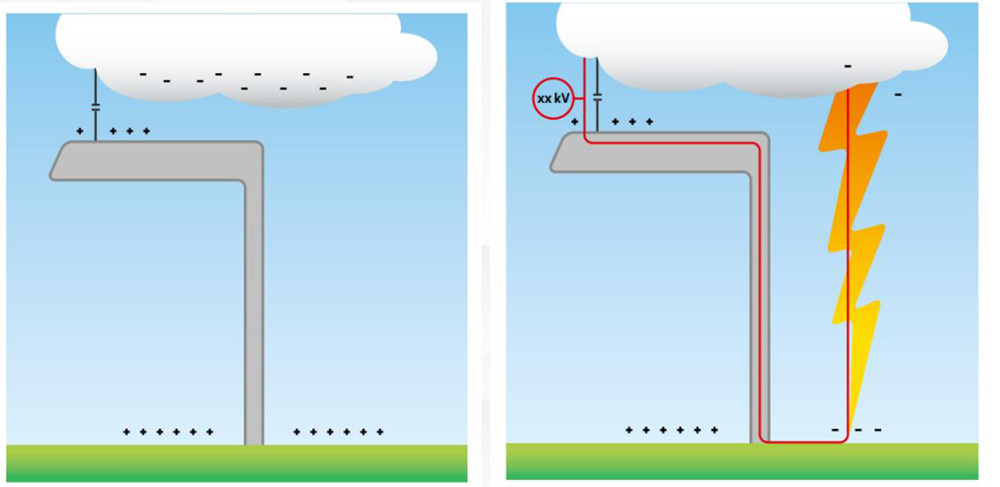

There is always a charge built up between the cloud and the earth. The eyes cannot see it directly at usual times, but it will be enough to initiate a lightning strike when the potential difference between the cloud and the earth is high enough.

The lightning strike is what we usually see called a “Direct hit”. However, what about the conditions before the lightning when there is not enough to initiate? The charge always exists and we call it an “indirect hit”. LED feels stronger for these Indirect hits than the human body.

How to avoid these “Indirect hits”? AGC Lighting suggests adding one more surge protection device to absorb the extra electric charge to protect the lighting fixtures, and please also pay more attention to the ground wiring so that the electric charges can be conducted to the earth.

Residual voltage

The explanation for Residual voltage is the voltage that remains in an output transistor while it is on. For example, consider an NPN output with a power supply voltage of 24V and a residual voltage of 2V. While the output transistor is On, there will be a 2V between the output line (the black wire) and the 0V line (The blue Wire). That extra 2V output may harm the LEDs because the electrostatics discharge ability for LED may be near or less than that 2KV. The better way to solve that kind of problem is to improve the voltage resistance ability. All the outdoor flood lights are improved from previous 1.5KV to 3KV now.

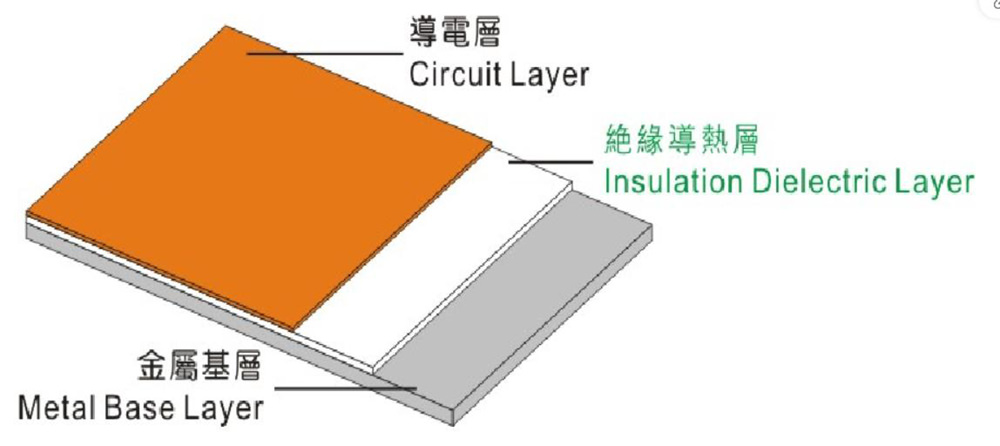

Insulation dielectric layer of PCB

There are always 3 layers for the PCB, including Circuit Layer, the Insulation dielectric layer, and the Metal Base Layer.

Some clients prefer to purchase the floodlight without the optic lens in stock and change the optic lens themselves. It is easy to damage the insulation layer, which means the LEDs are more easily damaged. So we suggest paying more attention to the torque force when fixing the screws on PCB.

LED Chips Electrostatic discharge

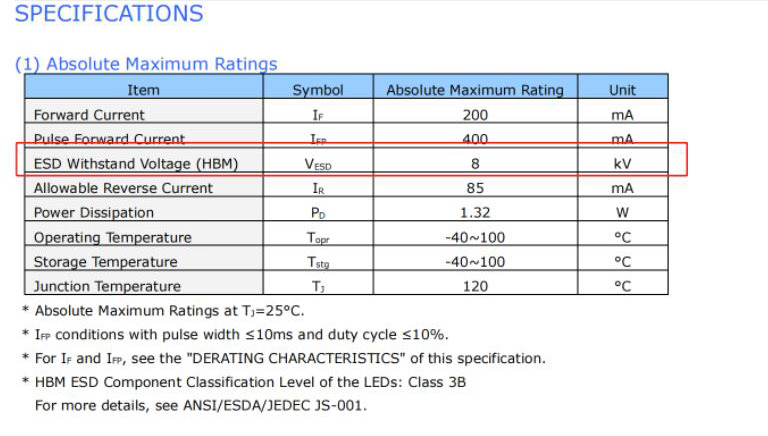

We mentioned the Electrostatic discharge when we talked about the Residual voltage. The way to solve that is to consider higher quality LED chips when purchasing that kind of product. The higher quality LED Chips will offer a much higher electrostatics discharge ability.

Most of the LED Chips including SMD3030, SMD5050, and SMD2835 offer 2KV Electrostatic discharge. The most common ones seen on markers are Lumileds, Seoul, Refond, etc.

AGC suggests the clients consider the Nichia chip for such kinds of applications, especially the areas easily happen with LED Chip damage such as Ireland, and the UK, the Nichia chip offers ESD 8KV which is much higher than the other's 2KV.

It is worth paying a few dollars more for outdoor flood lights with a higher quality LED chip to avoid the problems, after all, no one prefers to pay thousands of dollars more to rent the equipment to repair the fixtures.

Contact me for more details, AGC will be always your reliable partner.