Have you noticed purple streetlights? This unusual phenomenon is often caused by LED phosphor degradation. Over time, heat and vibrations can accelerate this process, leading to performance issues and color changes in LED streetlights.

The solution? High-quality, long-lasting LED streetlights that are built to withstand these challenges. But how can you be sure that the LED products you choose for your lighting projects will maintain their performance over time?

This is where industry standards like LM-79 and LM-80 come into play. These standards are essential for evaluating LED products, ensuring that they not only deliver impressive performance on day one but also remain reliable and consistent for years to come.

What Are LM-79 and LM-80, and Why Do They Matter for Your Lighting Projects?

LM-79 and LM-80 are two standards developed by the Illuminating Engineering Society (IES) to ensure the quality, performance, and longevity of LED lighting solutions. In lighting design and manufacturing, these standards play a critical role in evaluating LED products.

LM-79 focuses on testing the overall performance of a complete LED luminaire, including aspects like light output, energy efficiency, and color accuracy. On the other hand, LM80 measures the reliability and longevity of LED light sources by assessing how well they maintain their light output over time.

Why do these standards matter? In practical terms, they protect your lighting investment. LM-79 and LM-80 provide confidence that LED lighting solutions will perform as expected, both initially and throughout their lifecycle. With LM-79 and LM-80 reports, you can avoid costly mistakes, and ensure the solutions you choose deliver consistent, reliable, and efficient results over time.

LM-79: Measuring Luminaire Performance

LM-79 is a standardized method for the electrical and photometric measurement of solid-state lighting (SSL) products. It provides key data that helps evaluate the overall performance of a complete LED luminaire.

The LM-79 test measures critical performance metrics, including total luminous flux (lumens), luminous efficacy (lumens per watt), chromaticity, correlated color temperature (CCT), color rendering index (CRI), and luminous intensity distributions. Many of these values, like efficacy, CCT, and CRI, are commonly displayed on LED product labels to inform users about performance and quality.

However, LM-79 has limitations. It does not cover LED products that require external operating circuits or heat sinks, nor does it apply to fixtures designed for LEDs but sold without a light source.

LM-80: Measuring Lumen Maintenance of LED Components

Before diving into the details of LM-80, let’s understand why this standard is critical.

First, it’s important to clarify that the performance of Solid-State Lighting (SSL) products is not the same as the performance of the LEDs themselves. LED manufacturers test their products under controlled conditions: short pulses at a junction temperature of 25°C. However, in actual use, LEDs in luminaires operate at much higher temperatures, often between 60°C and over 100°C. Additionally, these LEDs are run in steady DC mode, not in short pulses.

The discrepancy between the controlled conditions of testing and the actual conditions of use means that it's crucial to have a standard method to measure the LED light source. The lifespan and performance of LED luminaires heavily depend on the performance of the LEDs within them. This is why the LM-80 standard is so important—it provides a consistent and reliable way to measure and report the lumen maintenance of LED light sources, ensuring they perform well over time in real-world conditions.

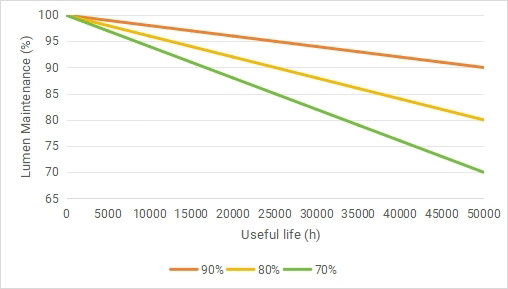

LM-80 is an approved method for evaluating the lumen maintenance of LED packages, arrays, and modules. It involves rigorous testing of LED components over an extended period—typically between 6,000 and 10,000 hours—to monitor how their light output diminishes over time. Think of LM-80 as a “health checkup” for LED light sources, revealing how well they maintain their performance over time.

Unlike LM-79, which measures the performance of complete luminaires, LM-80 focuses solely on LED components. However, LM-80 does not define or estimate the total lifespan of an LED product. Even with extensive testing for up to 10,000 hours, this period still falls significantly short of the claimed lifetimes of most solid-state lighting (SSL) products on the market today.

Differences Between LM-79 And LM-80

Here are some key differences between LM-79 and LM-80 standards:

|

Aspect |

LM-79 |

LM-80 |

|

Focus |

Performance of complete LED luminaires |

Lumen maintenance of LED packages, arrays, and modules |

|

Developed by |

Illuminating Engineering Society (IES) |

Illuminating Engineering Society (IES) |

|

Purpose |

To provide standardized performance data at initial use |

To predict the lifespan and reliability of LEDs |

|

Parameters measured |

Luminous flux, efficacy, chromaticity, electrical power, CCT, CRI |

Lumen maintenance over time at specified intervals and temperatures |

|

Usage |

Performances comparison of LED products |

Lifespan prediction and reliability assessment |

Are Values of LM-79 And LM-80 Reliable?

Yes, LM-79 and LM-80 reports are generally reliable because they are conducted under strict testing protocols and performed in accredited laboratories. These standards ensure consistent and accurate results across the lighting industry.

For most lighting manufacturers that do not have their own testing facilities, LM-79 and LM-80 tests are typically conducted by third-party laboratories. These labs follow the specific requirements outlined in the standards to deliver reliable results.

However, some large lighting manufacturers, like AGC Lighting, have their own in-house laboratories. While you might question whether results from internal labs are credible, there is no need for concern. For large lighting manufacturers, maintaining accurate results is not just about integrity—it’s also about protecting their reputation and building trust with customers. Moreover, these in-house labs are also required to be certified and regularly recertified by accredited external bodies. This rigorous certification process ensures the accuracy and reliability of the test results.