There are many special requirements for the luminaire in food processing plants and it is more and more important to select the appropriate LED light for your plant with the rapid development of manufacture. A food processing plant normally has partitions for raw material receiving, packaging, product inspection, processing, storing, etc. Every part should equipped with comfortable and sufficient lighting. For example, the light in the inspection area should be bright enough to help employees check whether the product is broken, damaged or with other quality problems. Besides, as employees need to work long hours, the light should be comfortable and will not cause eye fatigue due to glare.

This post will share with you the considerations and basic knowledge about indoor LED light in food processing. Let’s start it.

Certifications in Food Processing

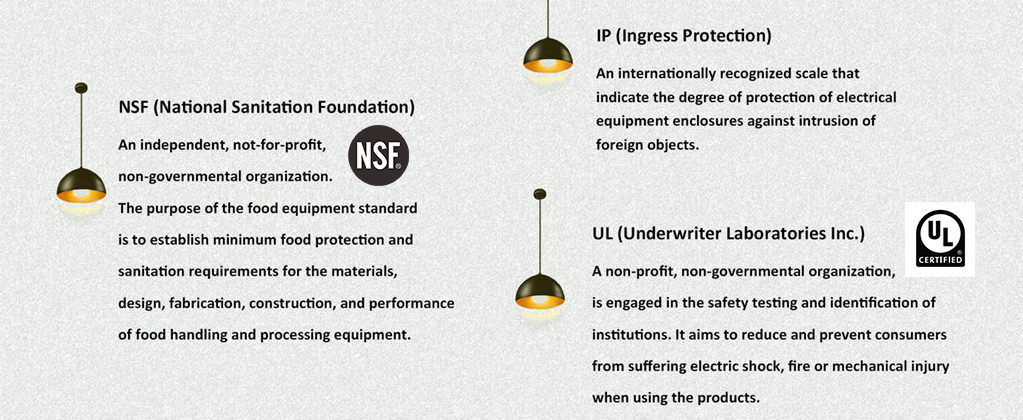

Different from other applications, food processing plants would pay more attention to food safety. It is critical for food safety as the food would be transported and then eaten by people in different places. If problems occur, a large number of people will be affected. Every step of food processing has relevant standards and certifications to optimize production and avoid any hazards to food products. To ensure safety, there are some certifications and standards that provide an easier way for you to choose the right light during the complex selection period.

NSF

NSF (National Sanitation Foundation), an independent, not-for-profit, non-governmental organization, is dedicated to being the leading global provider of public health and safety-based risk management solutions. The purpose of the food equipment standard is to establish minimum food protection and sanitation requirements for the materials, design, fabrication, construction, and performance of food handling and processing equipment.

The standard mainly indicates the following factors about the light in food processing.

- The light should be easy to clean.

- Made of smooth, no-hole and corrosion-resistant material.

- Designed to reduce dust and debris buildup, pest climbing and other possible hazards.

UL

UL (Underwriter Laboratories Inc.), a non-profit, non-governmental organization, is engaged in the safety testing and identification of institutions. UL certification is not mandatory certification, mainly responsible for testing product safety performance. It includes standards for mobile (portable) lamps and lanterns - UL153, stationary lamps and lanterns - UL1598, self-ballasted lamps and their adapters - UL1993, supplementary standard for LED lighting components - UL8750. It uses scientific testing methods to determine the degree of hazard to life and property of various materials, devices, equipment, buildings, etc., and aims to reduce and prevent consumers from suffering electric shock, fire or mechanical injury when using the products.

IP Rating System

IP (Ingress Protection) is an internationally recognized scale that indicates the degree of protection of electrical equipment enclosures against the intrusion of foreign objects. The protection level is mostly expressed by two numbers followed by IP, the numbers are used to specify the level of protection. “I” represents the level of protection against solid matter, the highest level is 6, while “P” represents the level of protection against water, and the highest level is 8.

There is the highest IP rating for LED light - IP69K.

IP69K means protection against close-range high pressure, high-temperature spray downs. It is not only dust-proof but also able to withstand high pressure and steam cleaning. The light rank IP69K is easy to clean and ideal for applications the equipment must be carefully sanitized.

Considerations of Food Processing Light

As mentioned before, the requirements of the LED light in food processing differ from other occasions. Glass, screws and other materials that may cause risks to food are not allowed to use in some food processing plants. All we concentrate on is safety.

The appropriate LED light plays a significant role in increasing output, reducing cost, and maintaining product safety. To achieve these goals, consider the following factors when choosing the LED light for a food processing plant.

Proper Illumination

Sufficient illumination levels are critical to the safety of both employees and food products. The reason for us to furnish LED light is to gain a higher visibility, so the proper illumination is really important. With suitable brightness, employees have a clearer awareness of the shape, location, and outlook of the product. It contributes to accomplishing better quality control and higher productivity during the production process. Additionally, employees feel safe as they know the location and quantity of people and objects around them, then they can avert dangerous or accidents, nevertheless while working or walking. Moreover, proper illumination would save energy costs as well.

Each part of plants shall equipped with the LED light in proper illumination according to the size and usage of the space. Managers often think lighting in the storage areas is unnecessary, but inadequate lighting will do harm to the product as it is not easy to notice the broken packaging or leakage of the product.

Then we should consider the quality of light as well. The fixture with qualified light can prevent glare or sparkle with appropriate illumination so that employees will not feel exhausted after a long time working. Only the employees work in a more enjoyable lighting condition, can they increase efficiency.

Material & Structure Design

The material of LED light for food processing plants shall be non-toxic, easy to clean, and able to withstand extreme temperatures. Besides, the materials are required to be durable, minimize maintenance costs, and prevent pests.

It is easy to understand why non-toxic materials are compulsory, the no-toxic material is risk-less to polluting the food products. The light free of hazardous flavor and coating makes it safe for both food products and employees.

Some food processing plants store food in warehouses with extremely low temperatures, like frozen meat, vegetables, and fruits. Others stock or produce food in high temperatures, like bread, biscuits, and braised food. Thus, LED light in food processing plants should be able to bear extreme temperatures while keeping good quality.

Normally, LED lights are suspended from the ceiling with the help of pendants, hooks, and chains, which means the lights are on top of producing areas or raw materials areas. It is essential to install explosion-proof light fixtures to avoid contamination of raw materials, products, and equipment. That is the main reason for most of LED lights are designed without glass.

The fixture must have no gaps or openings that permit bacteria, dust, or other particles from the plenum to leak into the prep area. So a no-screw design helps a lot to prevent former problems.

CCT & CRI

First, let’s learn about what CCT and CRI are.

CCT (Correlated Color Temperature), indicates the hue of a light source. What we usually explain as “cool white” or “warm white” refers to CCT.

CRI (Color Rendering Index) is the ability to reflect the true color of the item. The closer the color rendering index is to 100, the more natural the colors of the product will appear.

The LED lights with the ability to reveal the exact color of the food are important in some processing areas. It can not only promote efficiency for employees to inspect whether there are discoloration and contaminants in the product, but also offer a clearer vision of the food. The following pictures show the huge difference between different CRI.

Dust-proof & Water-proof

As demanded by NSF, LED lights in food processing plants should be designed to reduce dust and debris buildup, pest climbing, and other possible hazards. Smooth cases and no-exposed fasteners will not attract dust, debris, and pets. Well-sealed LED lights provide full protection and high performance for ensuring production safety.

Since most food processing plants have wash-down areas that are cleaned by spraying with hoses, the lighting used in these locations must be resistant and able to withstand the environment. Therefore, It is necessary for the light fixtures to be waterproof and able to perform smooth functionality in a wet and damp environment. We also notice that for a clean environment, sanitation and sterilization should be done every day in food processing plants. The LED lights with waterproof certification are ideal for this application. The higher the IP rate of the fixtures, the better the effect of dust and water resistance.

Solutions for Food Processing Light

We highly recommend two LED light fixtures for your food processing plants - HB21 HiAir LED high bay light and HB06 high bay light with red dot design award. Both of them are made of non-toxic material and have excellent performance in dust resistance and are waterproof.

Basic information is shown as follows. For further details, please feel free to contact us.

The light with a built-in microwave sensor can be turned on and off automatically at any moment. It also provides active dimming operation and saves more energy. The light can be set with a remote controller, which offers a more intelligent and smart way to meet your needs.

Lack of proper lighting can cause increased returns of food and beverage products, lower productivity within the plant, and less corporate profit can invite the threat of possible operation shutdown. Choosing the LED light with NSF and other relevant certifications, high CRI, and appropriate illuminates simplifies the compact picking process for your food processing plants.

Related video: