What questions should you ask first?

When customers inquire about LED light fixtures used for high-temperature applications, we need to know in advance.

1. The use of that place (Is it a steel mill or a warehouse with metal roofs?)

2. Is there any high-temperature equipment such as a boiler

3. The duration of the high temperature (Does it last for the whole year or just summer days?)

4. Light fixture working time per day

5. Light fixture wattage requirements

6. Light installation location and mounting height (Better provide the actual application photo to see the

location)

What challenges for LED light fixtures?

1. The service life of lights decreases (LED chips will decay faster, and the service life of the driver will decrease sharply)

2. The light failure rate will be increased.

What kind of solutions does AGC offer?

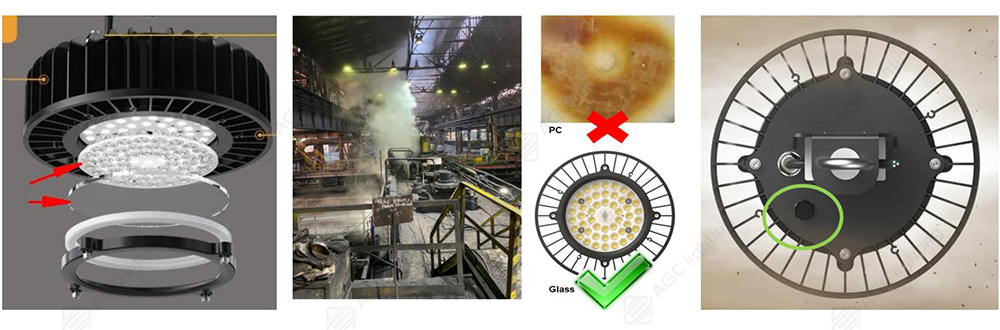

Below HB45 is tailored for Ta 70℃ high-temperature application, which is structurally designed with good ventilation and heat convection.

First, high-temperature sites normally with a lot of oil stains, which adhere to the PC lens, the heat of the lights cannot be dissipated, and high risk of chips burning, so HB45 is designed with a tempered glass cover to be resistant to oil. Second, some high-temperature sites have high air-tightness and high water vapor, LED light fixtures should enable a good air-tight structure and insert a vent/respirator, HB45 already with a vent.

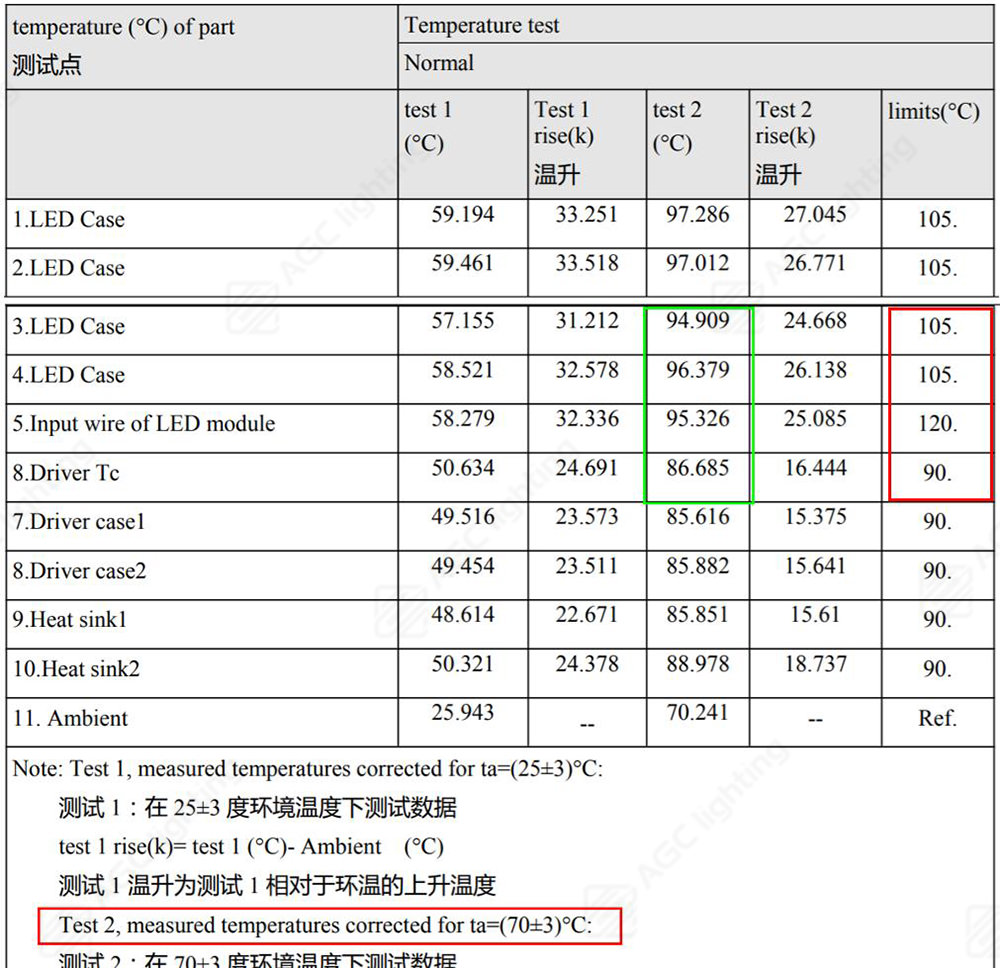

Let’s see the fixture’s Ta70℃ testing result, both LED case temperature and driver Tc value are less than their limitations. In short, HB45 is the best-in-class light fixture to help you meet harsh project needs.