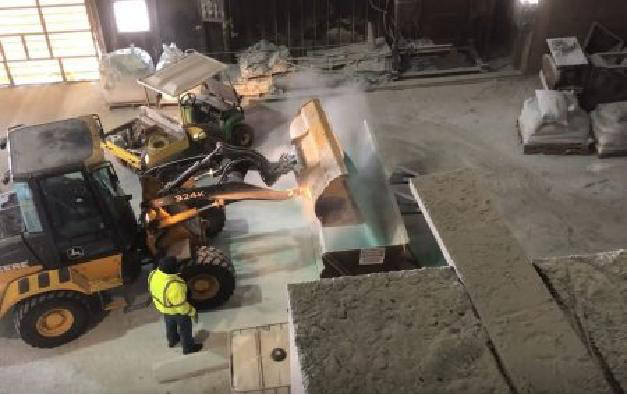

Have you ever met with problems choosing lighting products for wood mills, flour mills, paper mills, etc. where dust accumulates a lot?

If yes, let's discuss how to choose lighting products for heavy dusty places and make things simple.

Challenges of heavy dust places

Industrial sites are usually very large spaces, so lighting fixtures in most of the sites will not be regularly maintained, or cleaned like in household or commercial use. As the dust covers over the years, the power supply does not dissipate normally.

1, In the case of over-temperature protection, the power reduction will result in the reduction of brightness, or directly cause damage to the power supply.

2, At the same time, the heat generated by the lighting fixture will be backlogged, which will also make LEDs with too high temperature and damage the LEDs, so that the lighting fixture can not work normally.

How to solve the challenges

Therefore, when designing or selecting lighting fixtures, the priority is to think about whether the structure of light can effectively prevent dust or not. The less dust gathered the better. What's more, good air convection of each heating component is pretty important, to make sure excellent heat dissipation performance.

Suitable lighting fixture

For example, below HB06 with a large horizontal surface is not suitable, as dust will accumulate and does not fall easily. HB45 with a vertical type and hollow design heat sink to avoid dust accumulation, the back cover plate on the heat sink can isolate the dust as well.

Contact for more info, AGC will provide you with detailed and professional lighting solutions!