AGC Lighting is a company that specializes in industrial and outdoor lighting. With over a decade of experience, we understand the importance of safety in industries where volatile substances are present. That's why we have designed explosion-proof lights to operate safely in hazardous locations. This blog explores the significance of explosion-proof lights and highlights key features to consider when selecting these essential fixtures.

What Are Explosion-Proof Lights?

Unlike regular lights, explosion-proof lights are constructed to contain any explosion within the fixture, thus preventing it from igniting the surrounding atmosphere. These lights are commonly used in industries such as oil and gas, chemical processing, mining, and pharmaceuticals.

Importance of Explosion-Proof Lights

- Safety: The primary reason for using explosion-proof lights is safety. In environments where flammable substances are present, even a minor spark can lead to a catastrophic explosion. Explosion-proof lights are designed to eliminate the risk of sparking by ensuring that all potential ignition sources are securely contained within the fixture, thereby protecting both personnel and property.

- Compliance: Industries operating in hazardous environments are subject to stringent safety regulations. Using certified explosion-proof lighting helps companies comply with these regulations, avoiding potential fines and shutdowns.

- Durability: Explosion-proof lights are built to withstand harsh conditions, including extreme temperatures, corrosive substances, and mechanical impacts. This durability ensures a longer lifespan and reduces the need for frequent replacements, ultimately saving costs.

Key Features of Explosion-Proof Lights

- Robust Construction: Explosion-proof lights are made from sturdy materials like aluminum or stainless steel and often have a tempered glass lens to withstand impacts and prevent the release of any internal explosion into the surrounding environment.

- Sealed Enclosures: These lights have tightly sealed enclosures to prevent the ingress of dust and moisture, which could otherwise cause short circuits or corrosion.

- Heat Dissipation: Efficient heat dissipation mechanisms are integrated to prevent overheating, which could lead to ignition. This is particularly important for LED-based explosion-proof lights, which generate less heat than traditional incandescent bulbs but still require efficient cooling.

- Certification: Look for lights that meet industry standards such as ATEX (Atmosphères Explosibles), IECEx (International Electrotechnical Commission Explosive), and UL (Underwriters Laboratories). These certifications ensure that the lights have undergone rigorous testing and comply with international safety standards for use in explosive atmospheres.

- Energy Efficiency: Modern explosion-proof lights, often using LED technology, provide high luminosity with lower energy consumption, reducing operational costs.

Selecting the Right Explosion-Proof Light

When choosing explosion-proof lights, consider the specific requirements of your environment. Key factors to evaluate include:

Hazardous Area Classification

Determine the classification of your hazardous area. Explosion-proof lights are rated for different zones based on the type and frequency of hazardous material presence. For example, Zone 1 lights are suitable for areas where explosive gases are likely to occur in normal operation, while Zone 2 lights are for areas where explosive gases are less likely to occur.

— We got the whole certification to make the products suitable for different market's regulation. And our HA03, made from copper-free aluminum, can used in Zone 1/ Class I Division I; HA04, HA05 and HA06 can used in Zone 2/ Class I Division II.

Illumination Requirements

Assess the required level of illumination for your workspace. Consider the lumens output and the light distribution pattern to ensure adequate lighting coverage.

— Wattage range from 30W to 240W, with efficacy at least 140Lm/w and our HA06 is up to 160Lm/w,

Environmental Conditions

Evaluate the environmental conditions, such as temperature extremes, humidity, and exposure to corrosive substances. Choose lights with appropriate IP (Ingress Protection) ratings to ensure they can withstand these conditions.

— All of our Explosion-proof lights can achieve IP66&IK08, and our HA03 with its 12mm tempered glass can achieve IK10

Mounting Options

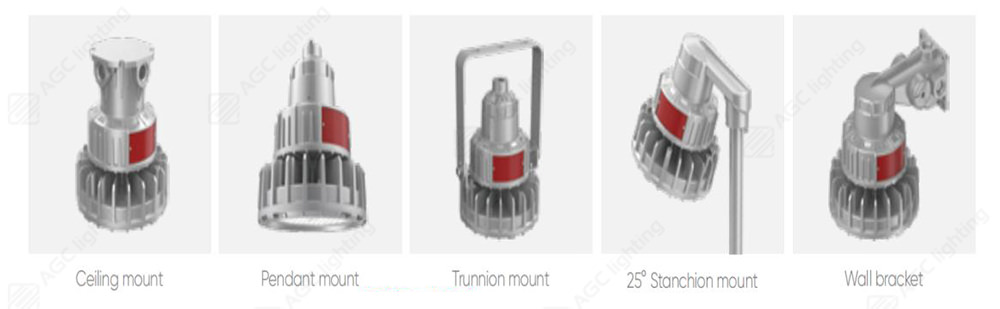

Consider the available mounting options, such as ceiling-mounted, wall-mounted, or portable units, to suit the specific needs of your application.

— Except above mounting options, we also have a Pendant mount, 25° Stanchion mount, Trunnion mount, etc.

Communication

Consulting with a specialist or the manufacturer can help you select the most appropriate lighting solution for your needs.

— We have a professional team that can provide you with instructive suggestion

Explosion-proof lights are indispensable in ensuring safety and compliance in hazardous environments. Their robust construction, sealed design, and certification make them a reliable choice for industries where the risk of explosions is high. Investing in quality explosion-proof lighting not only protects workers and assets but also enhances operational efficiency and peace of mind.

For more information on explosion-proof lights, visit our product page and contact us. We are happy to help you select the best lighting solutions for your hazardous environment.