Occupancy sensors are commonly used in commercial buildings. However, their application is not only limited to this field. There is also a place for them in industrial buildings like factories, warehouses, manufacturing plants, workshops, logistic centers, etc. These industrial buildings are often large in size. Lighting up all the space when no one is around is basically a waste of energy, especially in areas that are not used frequently.

As a matter of fact, there are many measures to reduce the lighting cost in those areas. As for how to choose, it depends on the specific needs and the project budget. Occupancy sensors are just one of them. But what exactly are occupancy sensors?

What are Occupancy Sensors?

An occupancy sensor is an electronic device that detects the presence of a person. There are various occupancy sensing technologies, but the most common are infrared, ultrasonic, microwave, and video image processing.

Infrared

A PIR sensor is an electronic sensor that measures infrared (IR) light radiating from objects in its field of view. It only detects general movement, but doesn't provide information on who or what moved. So the perceived objects are not only limited to people, but also animals or other moving objects. The way it acquires information depends on the infrared radiation (radiant heat) emitted or reflected by the detecting object, and does not actively radiate energy for detection.

Ultrasonic

Ultrasonic sensors emit high-frequency sound waves, outside of human hearing range, and then receive the reflected wave to detect if there are moving objects and measure the distance. The ultrasonic sensor sends out the detection signal actively, receives the return signal and interprets it. Like PIR sensors, it doesn't indicate what the detected object is.

Microwave

Microwave sensors work similarly to ultrasonic sensors. These sensors send out constant microwave signals into their environment. They then measure how long it takes for the signal to bounce back to the sensor. When something moves within the detection zone, the return signal will be interfered with and cause a delay. Microwave sensors detect this delay to determine the presence of moving objects. It also doesn't know what the moving object is.

Video Image Processing

Image sensors can convert incoming light (photons) into an electrical signal that can be viewed, analyzed, or stored. One of its more obvious features is the recognition of objects, so it is considered a promising technology.

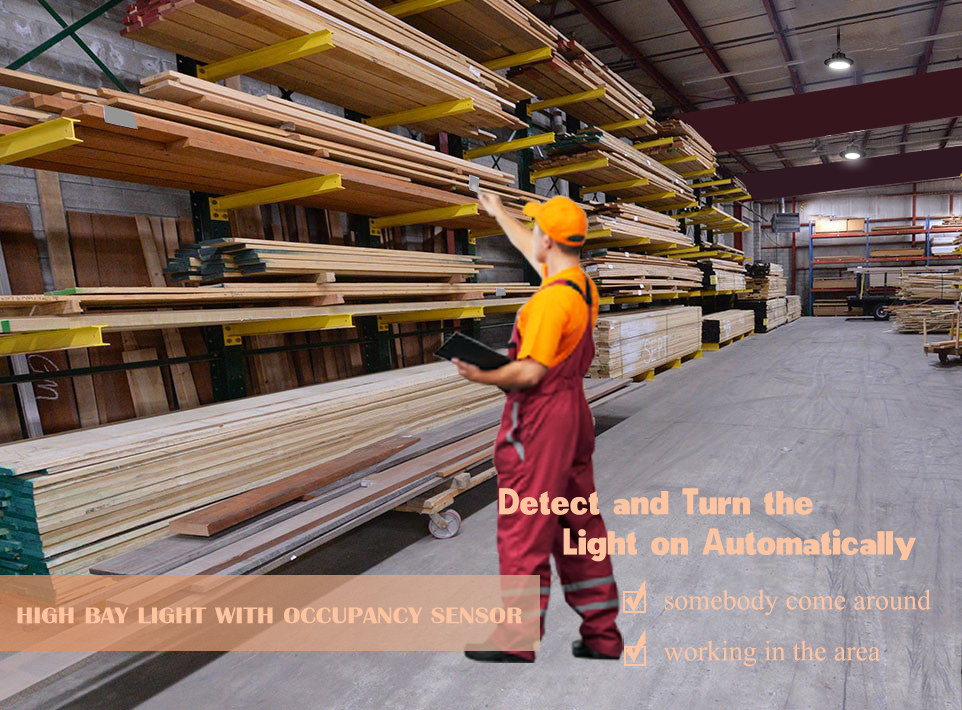

How High Bay Lights Work with Occupancy Sensors to Save Energy in Warehouses

In many warehouses or factories, there are certain zones where no one is working or people rarely use them. So there is no need to keep the high bay lights on all the time. You just need to make sure that when somebody comes around or is working in that area, the high bay lights are turned on—not too early or not too late—for people to operate there. By using occupancy sensors, it is entirely possible for business operators to save money on energy.

There are a lot of options when it comes to occupancy sensors in warehouses. They have different excellent performance. Here are two common ones that I want to show you:

As you can see in the picture above, the plug-and-play occupancy sensors are built into high bay lights installed in a lumber warehouse. With a PIR sensor built in the middle of the high bay light, when someone walks into the detect range, the PIR sensor detects the person's entry through their body's radiant heat. It then turns on the light and keeps it on until the worker leaves. After the worker leaves, the high bay light may go down from 100% to 20%, 15%, or 10% in a few minutes, depending on how you set it up. Eventually occupancy sensors confirm that the worker has not re-entered the area and the high bay lights are turned off again and return to their original state.

The performance of PIR sensors in complex spaces is slightly inadequate. The working process of microwave sensors is basically similar to PIR sensors, but with some differences. Microwave sensors don't rely on thermal radiation. They can actively send out detection signals to determine the presence or absence of persons within the inspection area. With occupancy sensors on LED high bay lights in a warehouse, it is really a great way to save energy, power and keep bills down.