With the rapid development of economy and fierce competition, the demand for lighting of the owners of enterprises shows higher requirements, which are no longer limited to providing basic brightness, but include providing appropriate brightness in different warehouse operation areas and creating a people-oriented lighting control mode. especially in the field of smart control, different lighting standards are required to provide for different operation areas . The traditional manual switch mode has been far behind the requirements of lighting control. whether to save energy or to improve the quality of lighting, Integrated intelligent lighting control system is the trend of lighting control and meet the need of control. DALI control protocol, as a typical open intelligent lighting energy-saving system protocol, also has been widely used in industrial lighting control.

DALI control, since being applied, has developed greatly. There are many cases of applying DALI system to LED industrial lighting in Europe and America. With the continuous promotion and application of led lighting, this technology will become more and more popular.

To be honest, DALI control can be combined with a wide range of led lighting, not only for general commercial lighting, but also for various industrial applications. In many large industrial lighting projects, it is a favored lighting control scheme, welcomed by business owners.

what is DALI ?

DALI (Digital Addressable Lighting Interface ), is a data transfer protocol.DALI defines digital communication between a lighting appliance and a system device controller. DALI control system brings great flexibility to the lighting control. the owners of enterprises can design and adjust the corresponding lighting scheme according to their needs. This adjustment can still be used during the operation after the installation of lighting fixtures like led high bay light and led linear high bay light without any changes to the circuit.DALI system is an ideal and simplified digital communication system specially designed to meet the needs of current lighting control technology.

how led high bay light work with DALI control in factory?

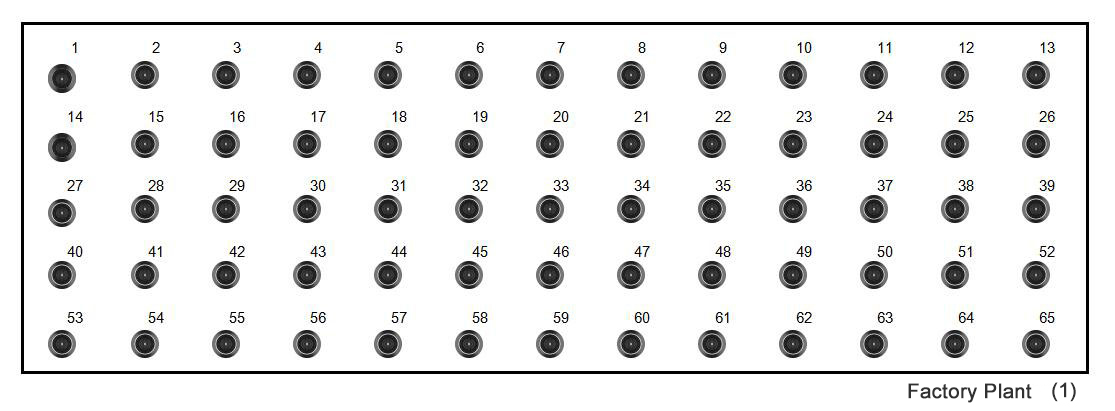

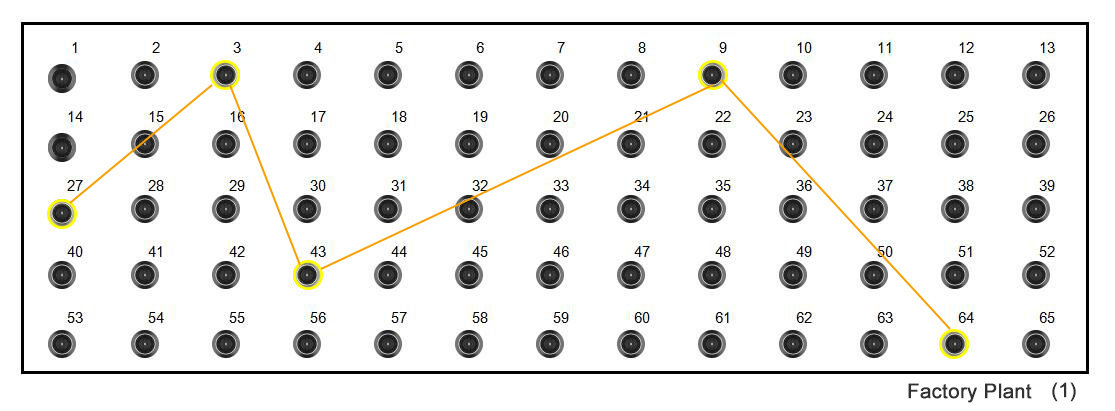

You must know that the reason why these led high bay lights can be intelligently controlled is not determined by the lamps themselves, but determined by the DALI ballast,DALI driver,DALI relay etc. they are usually used in conjunction with lamps. Suppose you have install our high bay lights in a factory in the way shown below (1) and give them a separate numeric address.

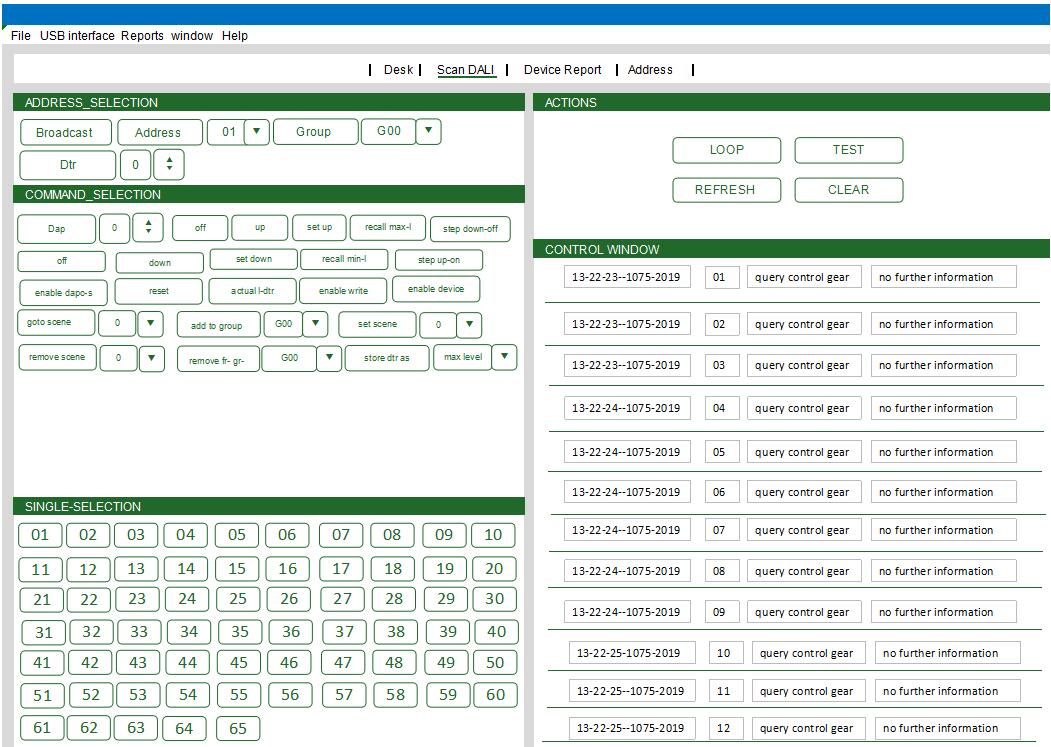

In a real application, the lamp's address is automatically generated by the dali-controlled interface through the gateway induction of the dali-controlled area .Of course, you can also go into the DALI app interface and modify it to make it easier to tag or fit your habits.Such operation is allowed, and many DALI app designers have considered this convenience property.

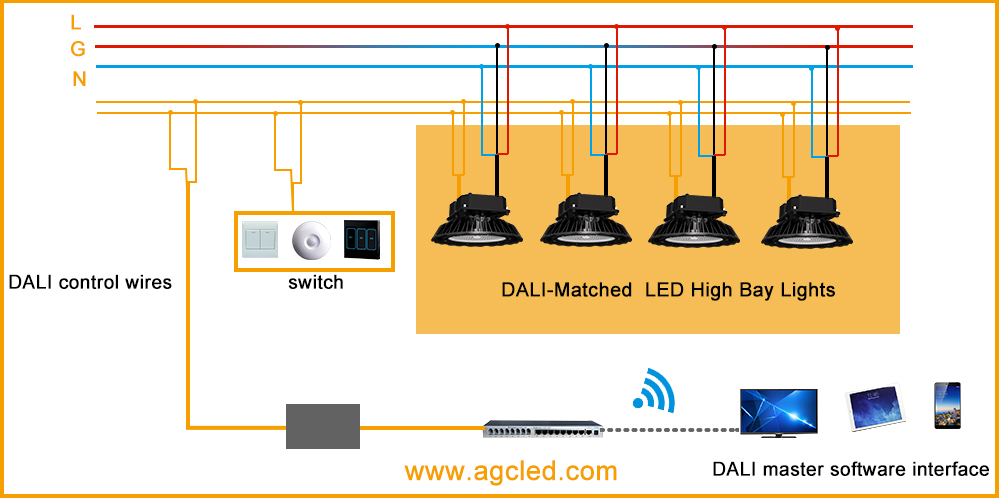

how led high bay lights connect DALI control ?

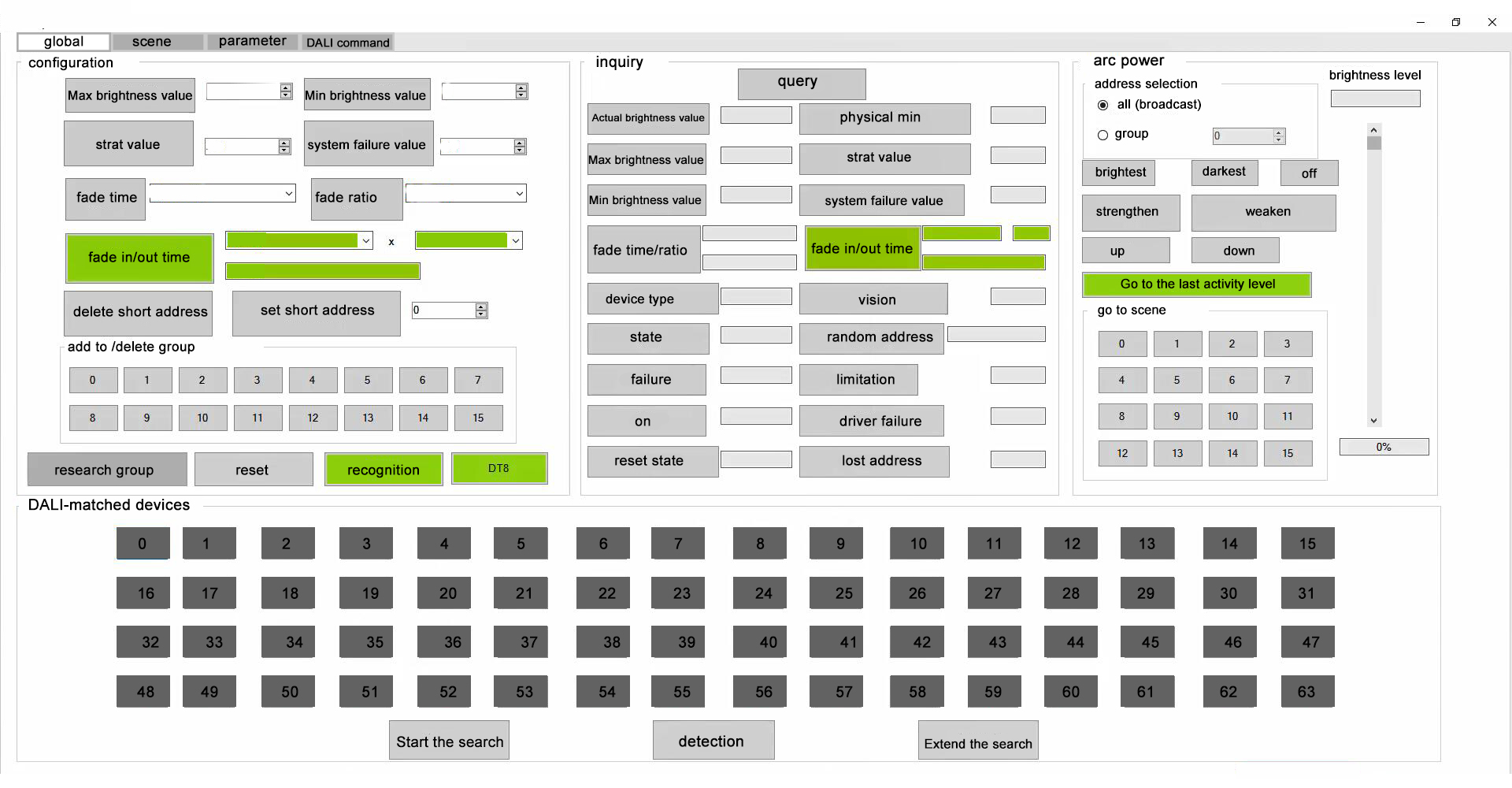

Generally the DALI-matched lamps can be seen in the DALI master software interface ,which is also we have mentioned above the “DALI app interface” DALI can achieve the function of

1) turn on /off the light (by single/ by group/by scene )

2) dimming up /down the light (by single/ by group/by scene )

3) detect the broken lights in all DALI-matched lights

4) monitor the condition of every light ( whether on or not ? whether broken or not ? The ratio of lumen output / Which group the light in ? )

5) adjust CCT (correlated color temperature )

6) control the lighting color of lights ( not for led high bay light)

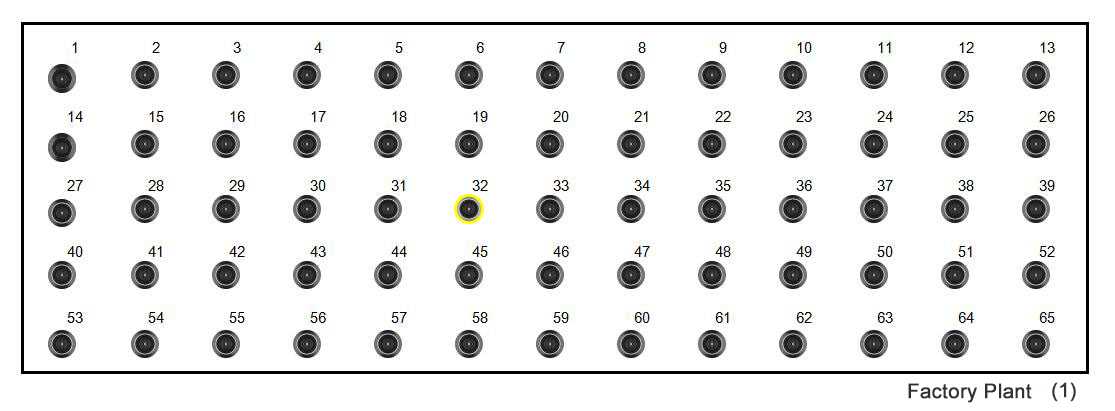

turn single light on /off :

all DALI-matched led high bay light can be randomly chosen to turn it on/off . in the figure below, the left figure led high bay light NO.32 is turned on singly, while in the right figure NO.34 led high bay light is turned off solely. you don't need to run around the factory to do the operation.all that can be done on the DALI master software interface.

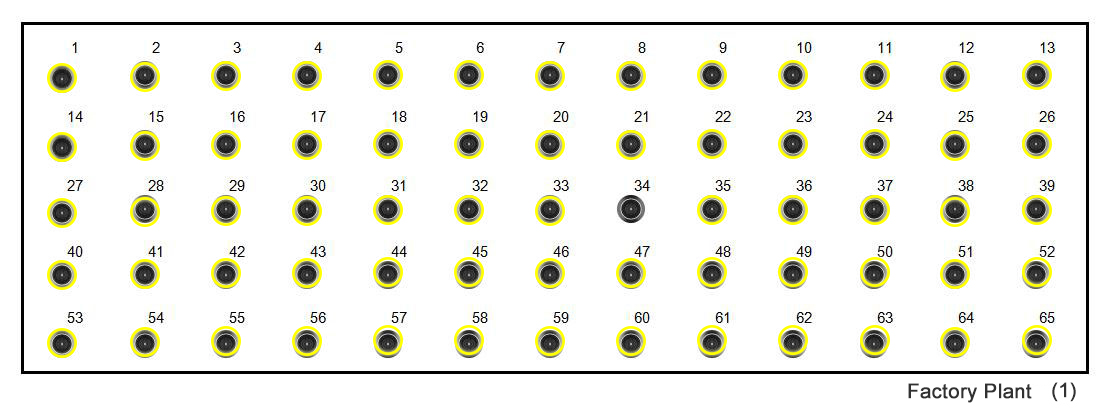

turn on/ off light by group:

You can group the lights you want to turn on as you like and control them through groups. This is more convenient than turning on the lights one by one, and you don't have to repeat instructions.

Now suppose you want to turn on lights NO.3, NO.9, NO.27, NO.43, and NO.64, and first you can group them through DALI and turn them on/off all at once. It doesn't matter how irregular positions they are.all operations will not be affected That is the benefit of DALI digital address location.

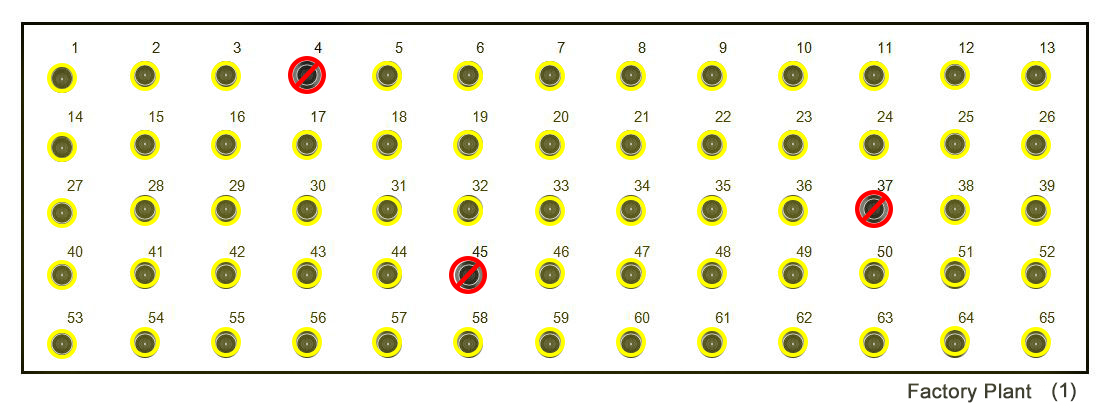

as for detecting the broken lights, DALI can detect if there are broken lighting fixtures in the factory. You can clearly be told which lamp is out of order in DALI master software interface and easily locate the lamp and fix it.DALI can only tell you which light is broken, but it cannot tell you exactly why. many vendors claim that DALI can detect what kind of glitches are occurring in the lamps. this is an exaggerated advertising that is currently impossible to realize.

If you haven't used DALI before, you must be curious about the interface of DALI master software. What are the functions above? Here are two of many DALI master software interfaces. Different DALI supplier, its master control software interface is not the same, the operation method is also different. So you need to consult before you apply it.

what benefits of led high bay light combine with DALI control ?

1) realize intelligent lighting control.

2) improve working environment and work efficiency.

3) provide uniform illumination.

4) considerable energy saving effect.

5) prolong lifespan of lights .

6) improve management level and reduce maintenance cost.

More and more lighting equipment, control equipment are equipped with DALI interface. DALI is more and more widely used, from a production workshop to a number of workshops and even the entire industrial park. especially for industrial production with large power consumption, the application of DALI control has great practical significance.