It goes without saying that lighting plays an important role in ensuring safety and security for workers in industrial environments. Last post we introduced the benefits of proper industrial lighting, including enhancing visual experience, reducing accidents, improving the working environment, decreasing health problems, and increasing productivity.

Proper lighting can also reduce electricity costs, which means more profits. For the industrial environment, the reduced cost of electricity could be a huge number. Those who ignore the usefulness of industrial lighting are missing out on momentous profits. But only having the knowledge of the benefits of proper industrial lighting is barely enough. We should learn how to improve industrial lighting performance as well. Generally, industrial lighting improvement is aimed to increase productivity as well as decrease energy costs. Ways for improving lighting performance in industrial environments are shown as follows.

Make full use of daylight

Most fixtures are on day and night in industrial environments. The long-term and continuous operation not only shortens the lifespan of fixtures but also wastes energy. Natural daylight is free and sometimes daylight is bright enough to meet the lighting requirements of some areas in industrial environments. Therefore, making full use of daylight is effective in improving industrial lighting performance.

There are two ways to utilize daylight. One is the interior design that approaches daylight while the other is the intelligent control that incorporates daylight.

Interior design approaches to daylight

Light filters into indoor spaces through windows or roofs. Moving the heavy machines or the works that require more light near the windows to maximize the use of daylight. Replacing the roof and windows with translucent materials allows more natural daylight transmit into the interior. Less fixtures and lower illuminance are needed for work as daylight helps to increase the ambient lighting.

Intelligent control incorporates daylight

Photosensors are the sensors that are used to incorporate daylight and control fixtures. Photosensors on or off the fixtures in terms of the amount of interior available daylight. With the assistance of photosensors, fixtures are turned off automatically when there is sufficient daylight in the interior. Intelligent control makes good use of daylight and helps to save energy consumption.

Increase lighting level and quality

Sufficient lighting is critical for the industrial environment. Lighting level requirements vary from area and task. To improve lighting performance, lighting level and quality should be increased. Increased lighting levels are beneficial for improving human visibility. Painting the wall or ceiling in white is a simple way to improve lighting level because it can reflect light more effectively to the ambient. But we should avoid excessive lighting and possible glare.

Lighting quality mainly consists of CCT (Correlated Color Temperature) and CRI (Color Rendering Index). CCT refers to the lighting color of light sources and CRI means the ability of a light source to show the actual color of the illuminated object. Lighting fixtures with CRI above 70 and CCT over 5000K can provide higher industrial lighting performance in common.

If current conventional fixtures cannot meet the lighting needs, you had better replace them with LED fixtures. If you have any problems with replacing conventional fixtures with LED, please feel free to contact us. Here is a table about the minimum and average lighting level requirements for different areas in industrial environments.

|

Areas |

Specification |

Average Illuminance (lux) |

Minimum Illuminance (lux) |

|

Circulation routes, corridors |

Areas without precise or hazardous works |

20 |

5 |

|

Loading bays, clearance sites, bottling, and canning |

Areas with hazardous but not precise works |

50 |

20 |

|

Large components assembling, potteries |

Areas with precise works |

100 |

50 |

|

Electronic components assembling, textile production |

Areas with fine precise works |

500 |

200 |

Avoid glare and shadow

Glare and shadow are the common issues of poor industrial lighting performance. They can lead to eye strain, headache, decreased visibility, and other discomforts that are negative to workers. Direct glare and shadow are normally caused by improper lighting installation or excessive lighting level. But indirect glare resulting from the light that is reflected by shiny surfaces is usually neglected. Ways for avoiding glare and shadows are as follows:

Glare

- Reduce the lighting level or remove the fixtures to decline brightness.

- Use blinds or curtains to shade the windows if the natural light is too bright to work.

- Avoid the workstations with glossy surfaces or cover the workstations with opaque material.

- Install the fixtures at higher heights or choose the shaded fixtures to avoid light filtering into workers’ vision directly.

Shadow

- Place the fixtures over or in front of the heads of workers in the working areas. Otherwise, the working areas will be shielded by workers themselves and they could only work in the shadow.

- Rise the fixtures. Shadow is less likely to appear with higher fitting height. If it is possible to recess the fixtures, recessed mounting is the optimal option to reduce shadow.

Use task light

As mentioned before, lighting requirements vary from work and area. Heavy machine working areas may be near the precision inspection workstations. Ambient lighting absolutely cannot meet the needs of the two working areas at the same time. Therefore, a task light (or portable work light) should be used. Workers are able to recognize the stains, damages, and other problems clearly. As errors are reduced, working performance and productivity are increased.

However, the positions of the task lights should be carefully selected. Glare and shadow are not permitted to appear with additional task lights. Task lights are added when the natural light or current lighting level is not adequate for work. Lighting levels that only ensure the basic visibility of workers are not sufficient for the areas with precise or dangerous work. Those areas require task lights to ensure safety and efficiency.

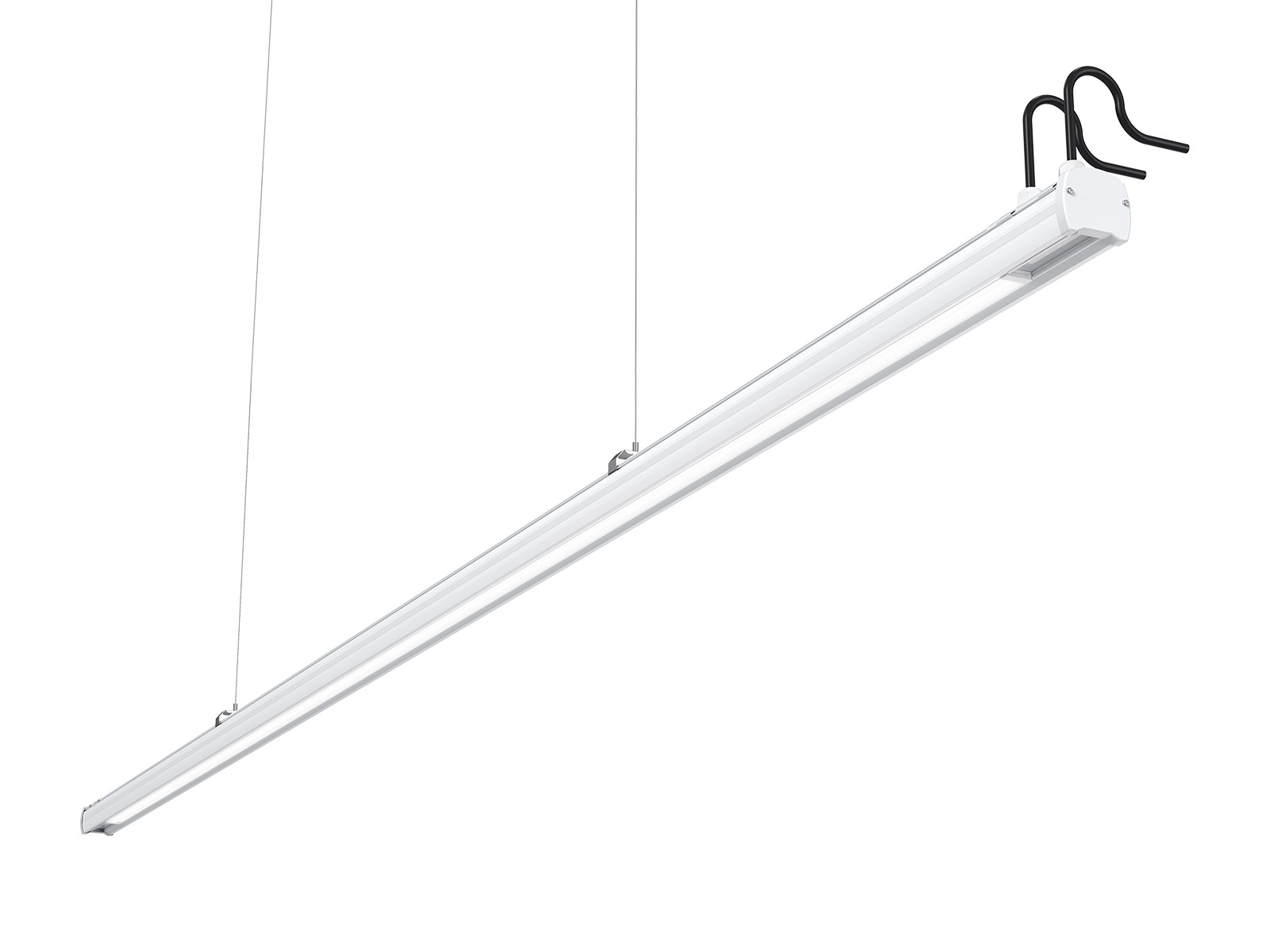

If the lighting condition cannot ensure the safety of workers, a portable task light shall be provided. FL26 portable work light is typically designed to ensure the safety of workers. It is easy to be taken out and can be fitted with a 90° optic lens. FL26 adopts the stainless steel plate and corrosion resistance front plate, tough and durable in any harsh working environment.

Cleanness and maintenance

Regular cleanness and maintenance are helpful in reducing total cost as well as improving industrial lighting performance. Not only the fixtures but also the environments shall be cleaned and maintained. Especially for food processing plants, all the exposed fittings including fixtures must be washable. Fixtures with NSF certification are typically designed for food processing plants. HiClean Plus is a breakthrough design in industrial lighting. Smooth housing is aesthetic and dust-proof. Non-toxic materials and non-exposed stainless steel screws make it ideal for food processing applications.

Here are some tips for improving industrial lighting through cleanness and maintenance aspects.

- Keep the windows or ceiling clean. With clean windows, more light can be filtered or reflected into working areas. It makes it possible to improve industrial lighting performance without increasing fixtures or lighting levels.

- Maintain and clean the fixtures regularly. Dust, pests, and other hazardous substances will affect heat dissipation and lighting performance. Regular maintenance prevents possible failures and poor lighting performance.