Industrial applications, especially those in harsh and hazardous areas, are more dangerous than others. Therefore, hazardous locations require higher protection of lighting fixtures to against corrosion, water, impact, explosion, etc. We have introduced the corrosion-resistance and impact protection of lighting fixtures in previous posts. Let’s take a look at the explosion-proof protection of lighting fixtures.

Hazardous locations, such as the paint spray booths, oil refineries, and grain processing plants, are facing the risk of fixture explosion due to the explosive gases, flammable vapor, dust, and fibers within the atmospheres. These applications often have limited entrance and exit points. If the explosion occurs, it may cause serious damage and injury. Explosion-proof lights are used in such locations to enhance safety and visibility. But industrial applications are of large size, each zones have different conditions. To provide precise and appropriate protection for fixtures in different hazardous environments, hazardous locations are classified by relevant directives and certifications, such as NEC, ATEX, and IECEx.

What are explosion proof lights

In simple words, explosion-proof lights are lighting fixtures that have a degree of capacity to isolate the fixtures from flammable substances and prevent ignition and sparks. Explosion-proof lights are usually utilized in hazardous locations, which refer to the areas where a large amount of volatile or flammable gas, vapor, dust, or fiber is present in the air. Common hazardous locations include paint booths, food processing plants, oil and gas refineries, fuel and chemical processing plants, etc. Most explosion-proof lights are equipped with rubber gaskets or encased in thick glass. The loose contact, wiring, or excessive heat may cause an explosion in a flammable environment. Explosion-proof lights can prevent ignition or sparks from escaping from the robust housing.

All explosion-roof lights must pass the relevant certifications and tests specified for hazardous locations from official institutions or organizations, such as the UL, CSA, NPFA, NEC, ATEX, IECE, etc. The three main certifications for electrical equipment in hazardous locations are NEC, ATEX, and IECEx.

NEC (Nation Electrical Code) is generally adopted in North America. It classifies the hazardous locations based on class/division and the zone.

ATEX is a certification that covers the devices and protective systems for proper use in explosive atmospheres. It is standard by the European Union to eliminate technical trade barriers.

IECEx (IEC System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres) is an international certification aiming to guarantee the highest level of safety of the equipment and the people in explosive atmospheres. Explosion-proof lights have a marking that indicates the protection level of the equipment.

Why explosion-proof lights are important

- Explosion-proof lights play an important role in ensuring safety in hazardous applications. Safety not only refers to the safety of fixtures but also to workers and the environment. Adopting explosion-proof lights in industrial areas reduces the risk of explosion and ignitions of fixtures effectively. It also protects the workers from injury. Since the explosion-proof lights will not react with the explosive atmosphere, the safety of the whole working environment remains.

- Implementing explosion-proof lights provides sufficient and safe lighting in a hazardous workplace. Since hazardous workplaces are in high danger, sufficient lighting is critical. Adequate lighting improves the visibility of workers. The bright and clear working environment enables workers to distinguish the surrounding environment and incoming materials, avoiding wrong operations and accidents.

- Using explosion-proof lights in hazardous places helps increase working performance and productivity. When the lighting fixtures are safe enough, the reliance on the lights will be increased. Workers can concentrate on their work instead of worrying about the unsafe light and explosive atmosphere. Once workers focus on the work, better working performance and higher productivity are achieved.

Classification of Hazardous Locations

Although all the fixtures that are typically designed for hazardous locations are called explosion-proof lights, they are not manufactured in the same way. The specific selection of explosion-proof lights depends on classification and the actual condition of the hazardous locations. Hazardous locations are mainly divided through two ways, the Class/Division system and the Zone system.

NEC Class / Division system

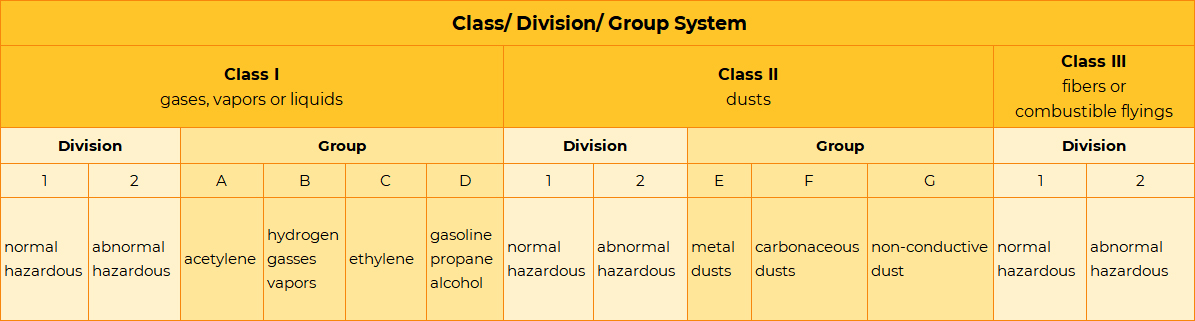

NEC classifies the hazardous locations into different classes, divisions, and groups. This classification system is based on the type, condition, and nature of hazardous locations.

-

Class

Class I: where flammable gases, vapors or liquids are present within the atmosphere.

Class II: where combustible dusts are present within the atmosphere.

Class III: where easily ignitable fibers or combustible flyings are present within the atmosphere.

-

Division

Division 1: normal hazardous operating conditions.

Division 2: abnormal hazardous operating conditions.

-

Group

The substances in hazardous locations are split into different Groups within the Class system. Class I includes Groups A, B, C, and D, while Class II contains Groups E, F, and G.

Group A: acetylene.

Group B: hydrogen, gasses, or vapors.

Group C: ethyl-ether vapors, ethylene.

Group D: gasoline, propane, alcohol, etc.

Group E: metal dust.

Group F: carbonaceous dust.

Group G: non-conductive dust, such as plastic, wood, grain, and flour.

ATEX Zone System

There are two ATEX directives, one for products (ATEX directive 2014/34/EU), and another for users (ATEX 1999/92/EC).

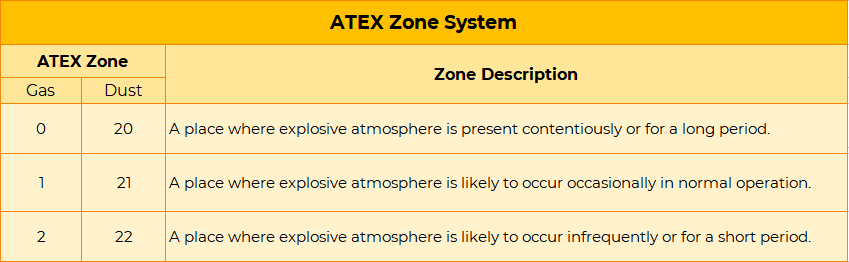

Let's take a look at ATEX user directive 1999/92/EC. This directive divides the hazardous locations into 6 zones, three zones for gases and the rest for dust substances.

-

Gas

Zone 0: a place where explosive atmosphere is present contentiously or for a long period.

Zone 1: a place where explosive atmosphere is likely to occur occasionally in normal operation.

Zone 2: a place where explosive atmosphere is likely to occur infrequently or for a short period.

-

Dust

Zone 20: a place where explosive atmosphere is present contentiously or for a long period.

Zone 21: a place where explosive atmosphere is likely to occur occasionally in normal operation.

Zone 22: a place where explosive atmosphere is likely to occur infrequently or for a short period.

We have introduced the concept and importance of explosion-proof lights, and the classification of hazardous locations (NEC Class/Division system and ATEX Zone system) in this post. Next time, we will talk about the marking of explosion-proof lights, more details about IECEx, and how to choose the right lights for hazardous places.