Generally, warehouses cover wide and large place, including elevated shelves, massive goods and few windows. It is popular for warehouses having high ceilings to store more goods in vertical forms. But warehouses are not only used for storage, they also worked as distribution center in common.

To increase efficiency, trucks, forklifts, stackers and other equipment are used for transporting and stocking goods. Employees read labels and inspect or pick the product in warehouses. They use lift to select the goods in higher locations. Forklifts and stackers traffic in aisles carrying goods in large scale and/or heavy weight. Aisles are the busiest parts in warehouses. Transportation, inspection, storage, selection and so on, rich set activities occur in racking aisles. However, most of aisles are long and narrow. Therefore, appropriate lighting for warehouse racking aisles is critical to ensure safety.

Importance of right warehouse aisle lighting

Save energy

Most warehouses are lighted for a long time, some of them even lighted up to 24 hours per day. Over working time will increase the risk of breakdown of fixtures, resulting higher maintenance cost. A cost-effective and energy saving lighting system is able to reduce electricity bill and maintenance cost. Right warehouse aisle lighting is equipped with sensor to adjust fixture on or off automatically. Or even better, come with controllable lighting intensity.

Reduce accident

There are a large number of heavy equipment in warehouse and they are often operated in aisle to transport goods. Right warehouse aisle lighting contribute to clearer vision of operators and help them recognize shelves and people better, being able to avoid accident or hurting people. In other words, warehouse owners can also reduce cost with the decrease of accident.

Increase productivity

Employees are less likely to sleep or feel exhausted in a bright enough and comfortable lighting environment, they concentrate on their work. On the contrary, glare and darkness will lower productivity. Sufficient lighting also makes clearer vision of the labels and locations of goods for employees, then they can pick the product fast and accurately.

Protect employees health

Glare can cause visual fatigue and damage to one's eyesight. In addition, the glare is very annoying as it often causes people to feel anxiety, lack of concentration and other psychological discomfort. It would cause serious insomnia and headaches even worse. Comfortable and qualified lighting can protect employees from glare. Employees are capable to work more efficiently with healthier body.

Warehouse aisle lighting considerations

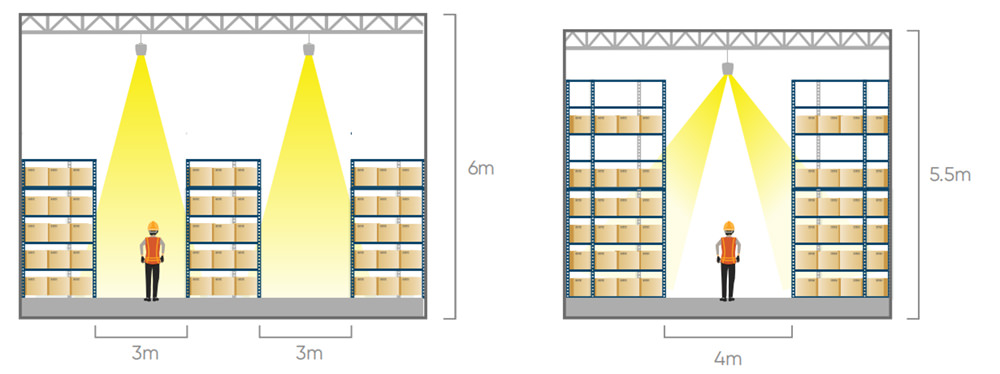

Warehouse lighting design varies from other places as it is not based on the dimensions of the whole warehouse but the rack areas, relating the length, width and height of racks and the height of ceiling. Fixtures can’t placed over the top of racks simply as warehouse are full of high racks, the racks will block the light and cause shadow. Moreover, if the fixtures are places too close to goods, the dissipated heat may cause fire. Aisle lighting is crucial for higher visibility. Fixtures are located in the middle of the aisle, avoiding shadow and darkness.

Right lighting for warehouse aisle is supposed to flux down on shelves efficiently and evenly as well as illuminate the floor correctly. Except for the lighting quality, such as the correlated color temperature and color rendering index, illuminance and lighting distribution are the key factors for aisle lighting considerations.

Illuminance

Warehouse lighting illuminance ranges from 150 to 300 lux generally. The main problem of warehouse lighting is how to balance the vertical and horizontal lighting needs as activities occur in both vertical and horizontal ways. Stacking the goods on shelves may only occurs in vertical way while transporting goods takes places horizontally. As primary lighting reference, Illuminating Engineering Society of North America (IESNA) has a design guide of warehouse lighting. Regarding to the guide, the recommended illuminance for rack area is 20 to 50 average maintain vertical footcandles and the vertical average to minimum ratio should be equal or less than 10:1. For horizontal illuminance, the horizontal average to minimum ratio should be equal or less than 3:1.

Lighting distribution

Most of the warehouse aisles are long, so common LED high bay lights in circular shape don’ t cover the aisle area evenly. Thus, linear high bay lights with rectangular spot are popular options for warehouse aisles.

The lighting distribution are designed according to racks layout. If the aisles are very narrow, the light with narrow beam angle will fit it. If not, the light should has wider beam angle.

Symmetric lighting distribution provide higher light level on shelves and aisles, the light on the floor is excessive as a result. The excessive light on floor is a waste of energy and it may cause glare. Asymmetric lighting distribution are more effective than symmetric lighting distribution. Asymmetric lighting distribution highlights the goods on shelves while reducing lighting levels on floor. Up to 35% of energy is saved in this lighting distribution. Because lighting level on floor is lower than shelves, glare is also reduced.

Intelligent sensors

PIR (Passive Infrared) sensor, motion sensor and photocell sensor are widely used in lighting control. A dimmable lighting system is efficient, flexible and economical. But integrated sensor has higher efficiency. If sensors sense the motion of people and then turn on fixtures suddenly, it will cause dazzle to employees’ eyes, which may led to accident. Or fixtures are turned off instantly but employees have not passed the aisles. A intelligent lighting sensor system should lit up the aisle in advanced to offer a smooth lighting for arriving employee. When the first light is on, the second light is also on immediately, offering continuous lighting. When it detects presence of any person or forklift working, the sensor would automatically dim light to low brightness or turn off after detection area is vacated for a period of time.

Warehouse aisle lighting solution

HiRack LED linear high bay is perfect for aisles in warehouse. Asymmetric optic lens adapts to narrow aisle between high shelves. The rectangular lighting pattern matches with aisles, which can effectively reduce lighting loss and waste and improve lighting uniformity. It can also provide intelligent lighting solutions by adding DALI, Zigbee, PIR sensor, motion sensor, daylight harvesting sensor, emergency, etc. Intelligent control helps to reduce electricity bill and lighting efficiency. More details, see following video.