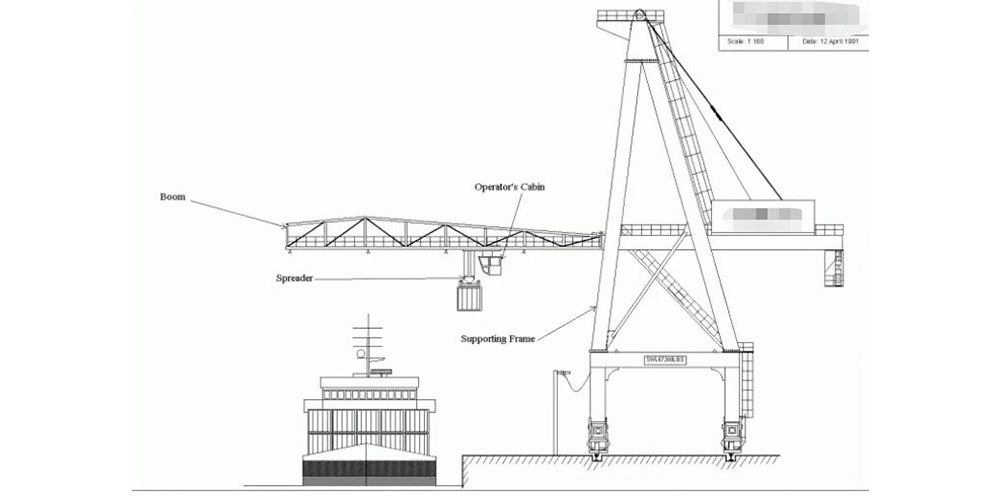

The modern container shipping industry is booming due to the provision for faster voyages and fewer port stays. The major factor behind this "quick work" is the introduction of new types of gantry cranes in the market, which are quicker and more reliable. This provides a great turnaround time for cargo operations at ports. But even the most efficient crane needs optimal conditions to operate safely and effectively. That’s where proper lighting comes in.

In this blog, we’ll discuss the essential lighting requirements for port cranes, ensuring smooth operations and maximum efficiency around the clock.

What are Crane Lights?

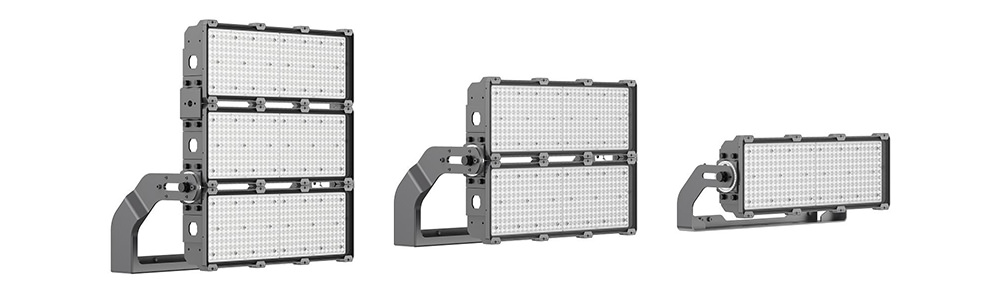

Crane lights are floodlights mounted on the underside of overhead or container cranes. Today, the workhorse of modern ports and industrial facilities, the crane, relies on LED crane lights. These aren’t your average floodlights, as you might have thought. LED crane lights are specifically designed to meet the demanding needs of crane operation, offering a unique blend of power, durability, and precision. They provide constant illumination, ensuring that the area below the crane remains consistently and evenly lit, regardless of the crane’s position or movement.

Three Special Lighting Requirements for Port Cranes

In an industry where every second counts and safety is non-negotiable, the adoption of proper LED crane lighting is critical. There are three main basic requirements for port crane lighting: vibration resistance, anti-corrosion properties, and a suitable beam angle.

Vibration Resistant

The constant movement of cranes presents a unique challenge for lighting: vibration. Vibrations can potentially cause damage to the fixtures, leading to failure and safety hazards. To address this issue, look for LED fixtures that have undergone rigorous testing according to the ANSI C136.31 standard. This standard evaluates the resilience of lighting fixtures against vibrations of varying intensities.

Generally, AGC LED fixtures are vibration-resistant and have passed the 3G vibration test, which subjects the lighting fixtures to up to 100,000 cycles of vibration. The 3G vibration test ensures that the LED fixtures can withstand vibrations with a peak acceleration of three times the force of gravity (3G).

Here is the video about the 3G vibration test:

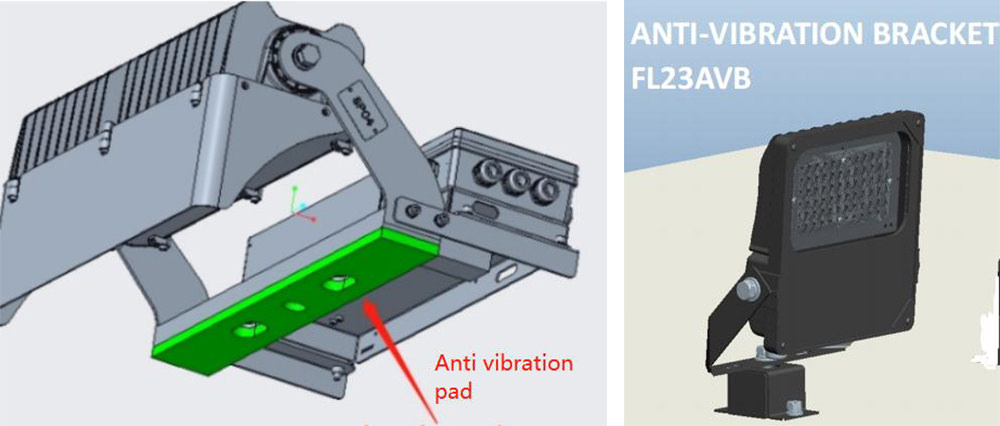

Except for the 3G vibration certification, additional measures are required to mitigate vibrations. We suggest adding anti-vibration pads or brackets for mounting the LED fixtures onto the crane. These pads act as shock absorbers, dampening the vibrations and minimizing the stress on the lighting fixtures, further extending their lifespan.

Anti-corrosion

The salty air and constant spray of seawater pose a significant challenge for any equipment operating near the ocean. For port cranes, this harsh environment demands lighting solutions built to withstand corrosion. Make sure to select LED floodlights with marine-grade finishes. These finishes are tough, durable powder coats, or epoxy-based finishes. Marine-grade LED crane lights also use 316 stainless steel screws and bolts.

While the terms "marine-grade" and "saltwater-tested" might sound similar, there's a crucial distinction. Marine grade signifies the materials and construction methods used to create a corrosion-resistant product. "Saltwater tested" might simply indicate the fixture was exposed to salt spray for a limited time. This doesn't guarantee long-term performance in a real-world port environment.

Below is AGC’s suggestion for marine-grade LED products:

FL23 Anti-corrosion Flood Light

FL35 Marine Grade Flood Light

SP12 LED Flood Light

Suitable Beam Angle

While high-power floodlights are the go-to choice for crane lighting, it’s not a one-size-fits-all solution. Choosing lighting fixtures with suitable beam angles is important. For cranes with booms positioned at heights above the ground, narrow beam angle patterns are recommended, as they concentrate the light output over focused areas, maximizing lighting efficiency. Conversely, wide beam angle optics are better suited for lower heights, providing a broader spread of light.

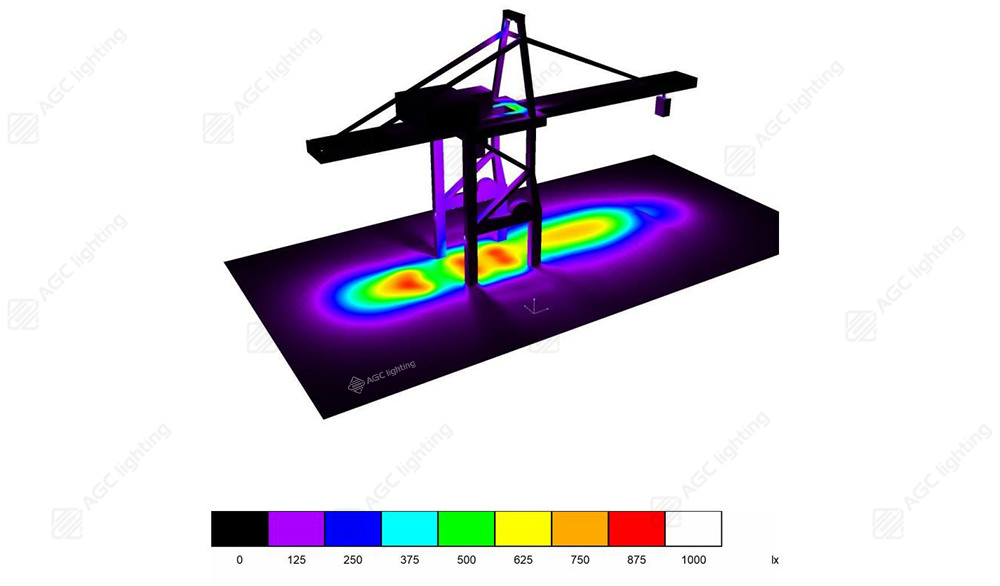

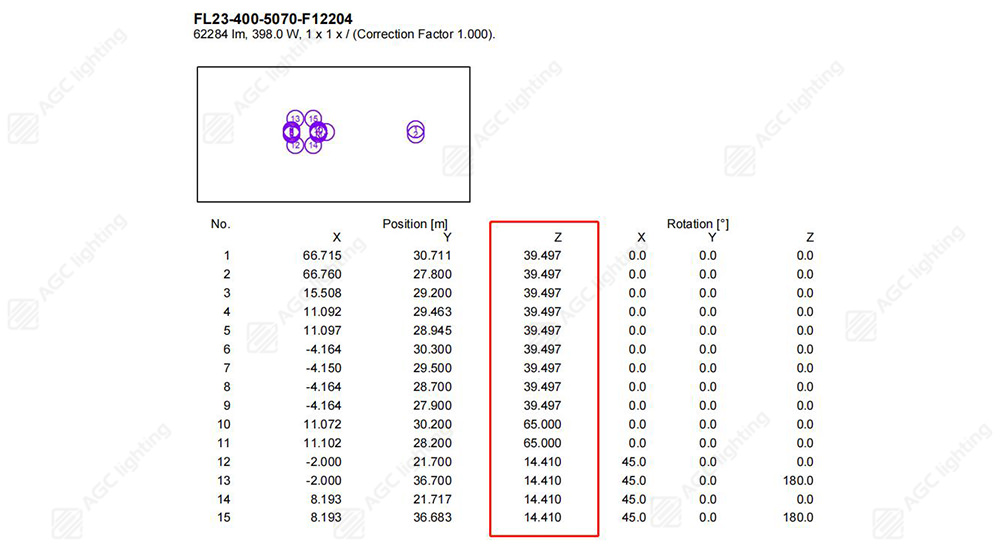

In short, crane lighting should be discussed case by case. There are no standard products for all projects. The best way to determine this is to create a DIALux lighting simulation. By providing information such as crane height, desired lux levels, and operational requirements, our team of lighting experts can generate a comprehensive lighting plan that specifies the optimal beam angles, luminaire power, and positioning to achieve perfect coverage and illumination for your specific needs.

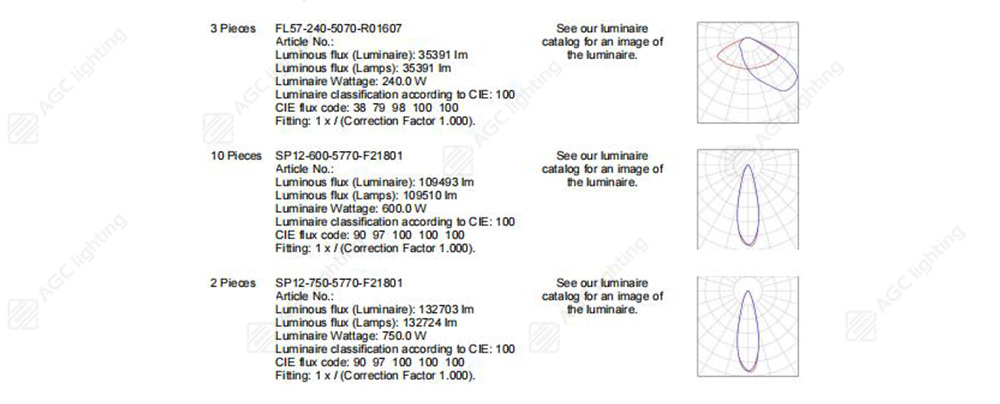

Here we have a lighting plan for reference. It shows the different powers/beam angles for different areas/heights.

Different mounting heights

Different beam angles