Does your industrial facility experience flickering lights, random equipment malfunctions, or electrical noise? These could be signs of a killer of the lighting system: dirty power.

Dirty power, refers to the irregularities and disturbances in the electrical current that can wreak havoc on sensitive equipment. Dirty power leads to costly downtime, safety hazards, and decreased productivity. It is a growing concern in the industrial landscape, particularly heavy and hazard industrial facilities.

But fear not, there are some effective solutions to overcome dirty power. In this blog, we will explore the dirty power, its manifestation, its causes, and how to overcome it.

What is dirty power

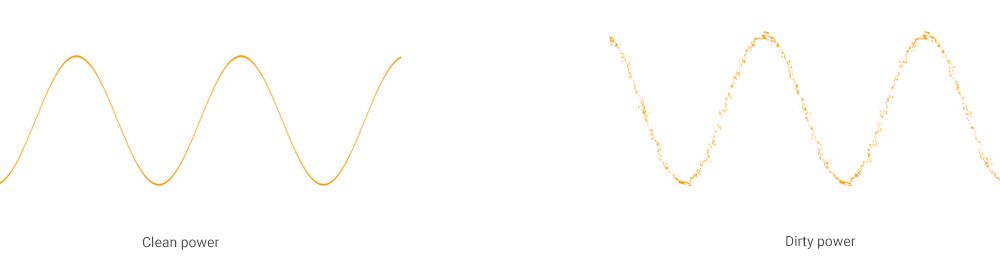

Dirty power, also known as electrical pollution, refers to the presence of distortions, disturbances, or deviations from the ideal sinusoidal waveform in an electrical power supply system. It can manifest in voltage fluctuations, frequency variations, and electromagnetic interference. Dirty power can degrade the quality and consistency of the electrical power delivered to lighting systems.

Clean power vs. dirty power

Clean power, with its pristine sinusoidal waveform, is like a smooth highway, delivering a consistent flow of electricity (voltage and frequency) to keep your lighting fixtures running smoothly.

Dirty power, on the other hand, with its harmonic distortion, is like a bumpy road. The laden with surges and anomalies can degrade lighting systems and pose safety risks.

Why dirty power matters

Dirty power impact transcends mere inconvenience, striking at the heart of efficiency, reliability, and profitability.

- Lost productivity: Dirty power can cause equipment malfunctions, unexpected shutdowns, and data loss. These disruptions translate to lost production time, missed deadlines, and ultimately, lost revenue.

- Equipment damage: Voltage spikes and fluctuations can stress and damage sensitive electronic components in your machinery. This leads to premature equipment failure, requiring costly repairs or replacements.

- Safety concerns: unstable power can lead to overheating and electrical arcing, posing a significant safety hazard for your workers. Additionally, malfunctioning equipment due to dirty power can increase the risk of accidents.

- Hidden costs: While the initial cost of dirty power solutions might seem like an expense, it’s an investment that pays off in the long run. Reduced downtime, extended equipment, and improved safety all contribute to significant cost savings.

How to detect dirty power issues

Detecting dirty power issues is the first step towards mitigating their harmful effects. Here are some key symptoms to watch out for:

- Flickering or dimming lights: If you notice your lights flickering or dimming, it could be a sign of electrical disturbances. Dirty power can cause fluctuations in voltage, leading to inconsistent lighting conditions.

- Unusual electrical noises: Pay attention to any unusual buzzing, humming, or crackling sounds coming from your lighting system. These noises may indicate the presence of electromagnetic interference caused by dirty power.

- Overheating: If your lighting fixtures are hot to the touch, it could be a sign of dirty power. Harmonic distortions and voltage irregularities can cause increased heat generation in lights, leading to overheating and potential damage.

To accurately identify these power quality issues, specialized tools are required. An electromagnetic interference (EMI) meter can measure the high-frequency noise. Others, like the spectrum analyzer or oscilloscope, can offer insights into the magnitude and frequency of the electrical noise.

What causes dirty power

Dirty power is caused by a variety of factors that introduce unwanted high-frequency electromagnetic signals into the electrical wiring system. These disturbances can originate from external and internal sources.

External sources

Lightning strikes, power line faults, or severe weather conditions can cause voltage spikes and power surges, leading to dirty power. These events can introduce sudden and unpredictable electrical disturbances into the power grid.

Internal source

- Poor electrical wiring and grounding: Inadequate or faulty electrical wiring and grounding can contribute to dirty power, issues like loose connection, improper grounding, or damaged wiring can introduce electrical disturbances and disruption into the power supply.

- Large power fluctuations: Sudden changes in power consumption with your facility, like the starting up and shutting down of heavy equipment, can create surges and sags, impacting the lighting system.

- Load imbalance: Uneven distribution of loads across the three phases of a three-phase electrical system can lead to voltage unbalances and increased neutral currents, contributing to harmonic distortion.

- Aging infrastructure: Outdated or poorly maintained electrical infrastructure, including transformers, cables, and switch gear, can contribute to power quality degradation due to increased impedance or internal faults.

Solutions to overcome dirty power

Here are some effective ways to overcome dirty power:

Industrial-grade LED fixtures with surge protection

Choose industrial-grade LED lighting fixtures equipped with high-quality power supplies and integrated surge protection to effectively counter the adverse effects of erratic power supply. Although it is challenging to completely eliminate power fluctuations, the installation of industrial LED fixtures capable of withstanding such conditions will serve as a reliable safeguard against failure.

Our explosion-proof lighting fixtures are meticulously engineered to incorporate 10kV surge protection for harsh and hazardous industrial environments. This enables the fixtures to promptly neutralize or absorb sudden surges in electrical current during power fluctuations. By preventing any potential damage caused by surges, these fixtures ensure seamless operation and prioritize the safety of employees involved in critical processes.

|

HA03 |

HA04 |

HA05 |

Power conditioners or voltage regulators

Power conditioners and voltage regulators help maintain a stable and consistent voltage level, filtering out unwanted harmonics and fluctuations. These devices ensure that your appliances receive clean power, protecting them from the adverse effects of dirty power.

Turning off devices when not in use

Turning off appliances and devices when not in use is a simple but also effective practice that extends far beyond energy conservation. By adopting this habit, you are actively against the internal generation of dirty power.

Conduct regular maintenance

Regularly inspecting and maintaining your electrical infrastructure is crucial for identifying and addressing potential dirty power issues. Check for loose connections, damaged wiring, or faulty equipment that could contribute to electrical pollution. Timely repairs and maintenance can help prevent dirty power problems from escalating.

Upgrading electrical infrastructure

Sometimes, the best defense is a good offense. In cases of severe dirty power issues, upgrading your electrical infrastructure may be necessary. This could involve replacing aging wiring and transformers to handle the demands of your modern facility.