Coastal areas can be a big challenge for outdoor lighting, as the sea spray and salty air can rust the aluminum, which will damage the air tightness of the lamp. So that vapors will easily go into the lamp and affect the lifespan. The rusted bracket, for a long time, will have the risk of falling off and being dangerous to people walking by. In addition to the risk of people, a constant investment in maintenance will be a heavy burden for the project supplier.

Below are some complaints we received from customers using normal flood lights on the beach for only a few months. You could see the top coating had fallen off and the aluminum was rusted.

How to prevent this problem?

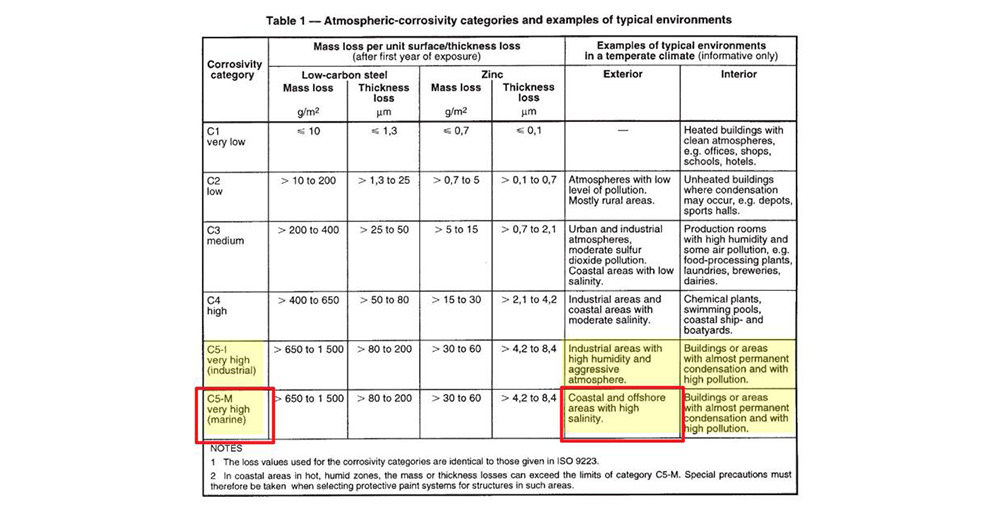

There is an ISO standard numbered 12944 that provides the solution. ISO 12944 is one of the most important international standards for the protection of steel against corrosion by protective paint systems. In this ISO standard, painting systems used in coastal and offshore areas with high salinity should meet corrosivity category C5-M.

How to know if the painting system is C5-M resistant or not?

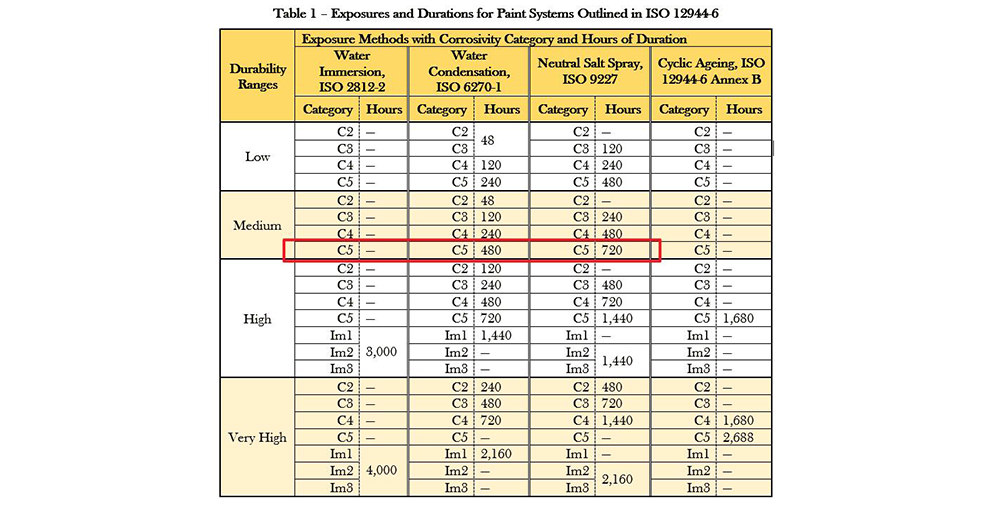

ISO 12944 Part 6 defines that the C5-M painting system should pass at least 480 hours of water condensation and 720 hours of netural salty spray while still in good condition.

How long would the C5-M painting system last?

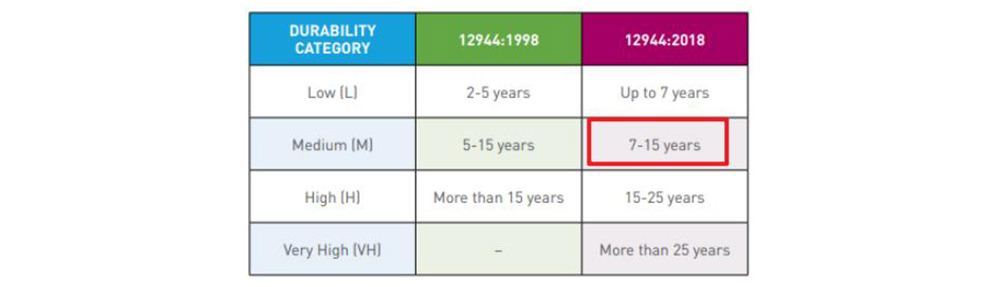

Each corrosivity class is sub-divided into three durabilities, the durabilities represent the approximate service time expectancy. In each corrosivity class, Medium (M) represents 7–15 years.

What can AGC offer?

We have lots of flood lights, street lights, and sport lights with C5-M or even C5-H ready for coastal and offshore projects. Below are our standard flood lights with C5-M and C5-H for your information.

Welcome to contact us if you need any help from us.

Learn more about the secrets of corrosion in LED fixture: