We have introduced the concept and importance of explosion-proof lights, and the classification of hazardous locations (NEC Class/Division system and ATEX Zone system) in the last post. We would like to talk about how to select the right explosion-proof lights for specific hazardous locations. Firstly, we will show the classification of equipment in hazardous areas. Next, we will take a look at the marking of explosion-proof light with different certifications. At last, we will indicate the explosion-proof lights catering to specific hazardous locations.

As soon as identifying the hazardous areas in industrial applications, it is critical to select the appropriate explosion-proof lights. Wrong decisions may cause severe ignition or explosion in the workplace. It may cause the injury of workers even worse. However, it is not easy to choose the right one between tremendous lighting fixtures. Except for the hazardous location classification, we should also learn about the category, protection type, and protection levels of equipment in hazardous locations. Only by applying the lighting fixtures in the right category or protection level to specific hazardous locations, can we maximize prevention of the danger and accidents.

Explosion Proof Equipment Classification

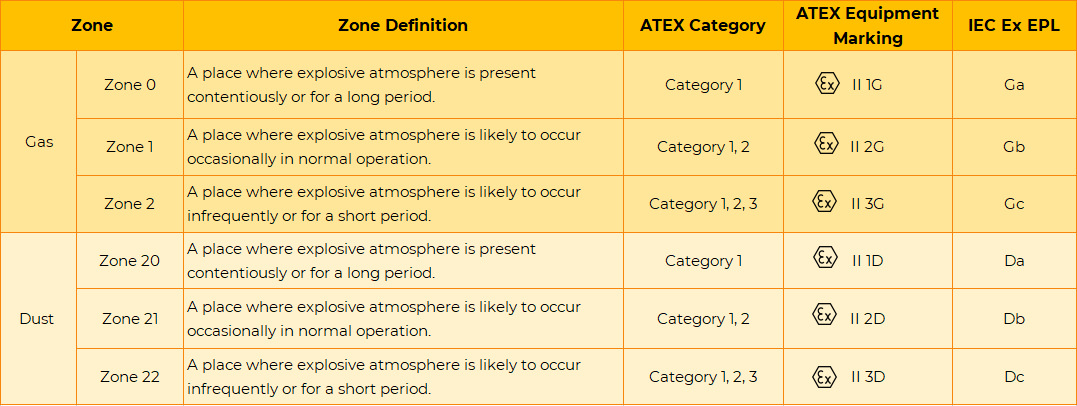

To apply the right explosion-proof equipment for hazardous areas, equipment is classified into different categories, protection levels, and protection types by ATEX and IEC.

-

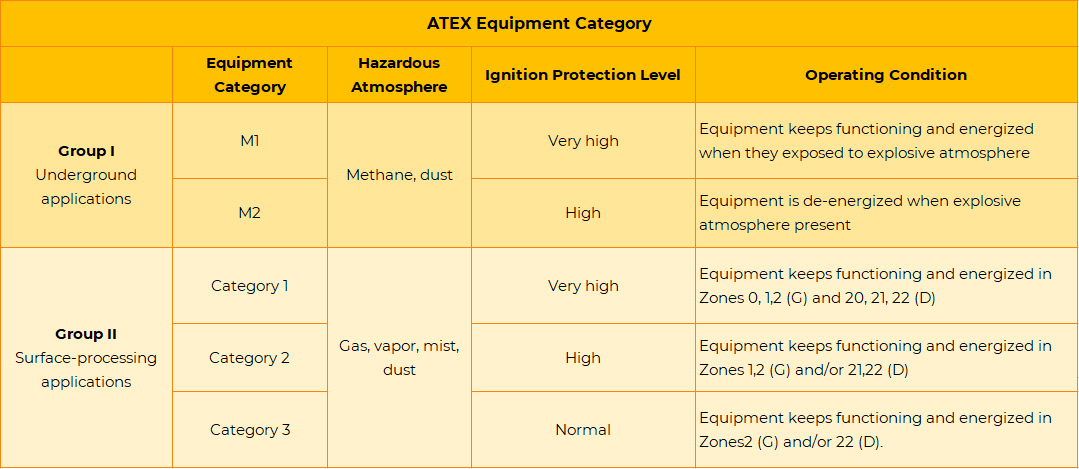

ATEX Equipment Category

ATEX product directive 2014/34/EU defines three equipment groups. Then group I is divided into two equipment categories, which define the protection level of equipment. Group II is divided into three categories.

Group I: equipment used in underground applications where flammable methane and dust are present within the atmosphere.

Group II: equipment used in surface-processing industrial applications where flammable gas, vapor, mist, and dust are present within the atmosphere.

Category of equipment:

M1: very high level of ignition protection, equipment keeps functioning and energized when they exposed to an explosive atmosphere.

M2: high level of ignition protection, equipment is de-energized when an explosive atmosphere is present.

Category 1: very high level of ignition protection, equipment keeps functioning and energized in Zones 0, 1,2 (G) and 20, 21, 22 (D).

Category 2: high level of ignition protection, equipment keeps functioning and energized in Zones 1,2 (G) and/or 21,22 (D).

Category 3: normal level of ignition protection, equipment keeps functioning and energized in Zones2 (G) and/or 22 (D).

-

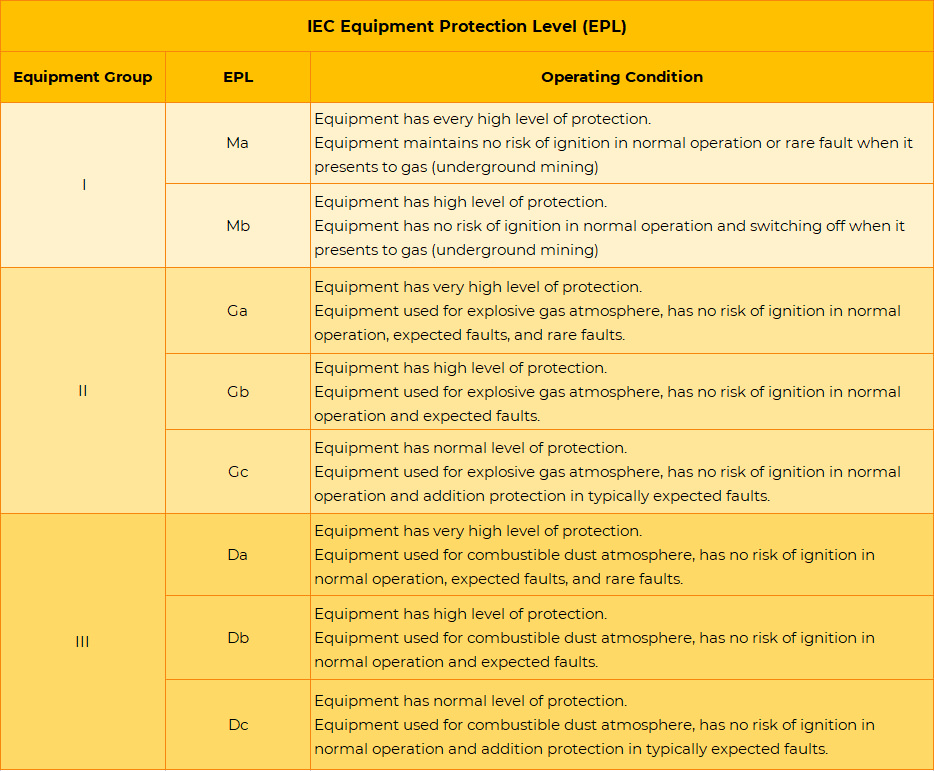

IEC Equipment Protection Level (EPL)

Equipment protection level indicates the protection level to a, b, and c in line. “a” refers to a ‘very high’ level of protection. “b” means ‘high level’ of protection. “c” expresses the ‘normal level’ of protection. The table of the definitions of EPL is as follows:

-

IEC Equipment Protection Type

IEC defines various protection levels for the equipment. Criteria that are applicable to different types of protection of explosion-proof lighting fixtures are as follows.

Ex d: A type of protection responds to the European standard EN 60079-1. It refers to flame-proof protection. The enclosure or housing of the electrical equipment can withstand the possible internal explosion and prevent transmission to the surrounding explosive atmosphere. “EX d” protection level will not be affected over time. Thus, it maintains the validity for most hazardous locations. Lighting fixtures with this type of protection are usually made of aluminum alloy material.

Ex e: A type of protection responds to the European standard EN 60079-7. Electrical equipment with this type of protection is constructed to reduce the possibility of arcs sparks or excessive temperatures which may cause an explosion. This type of protection often uses plastic resins to achieve resistance to marine corrosion and acids.

Ex i: A type of protection responds to the European standard EN 60079-11. It refers to intrinsically safe protection. The electrical equipment cannot cause ignitions with explosive atmospheres regardless of normal or abnormal conditions.

Ex n: A type of protection that electrical equipment is not capable of igniting the surrounding explosive atmosphere in normal operation. This kind of protection does not cover faults or abnormal conditions. “Ex n” protection is particularly utilized in producing lighting fixtures.

Since each type of protection concentrates on a certain feature, lighting fixtures may combine various types of protection. For example, “Ex e” protection only focuses on the non-sparking part of the enclosure. So, it is often used with other types of protection.

Marking of Explosion-proof Light

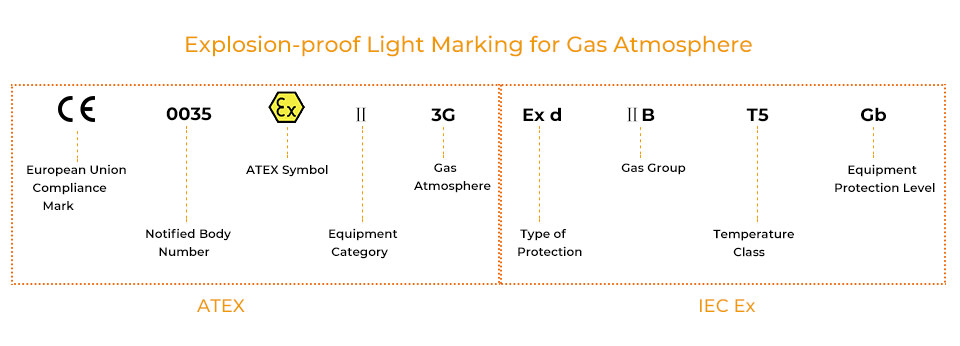

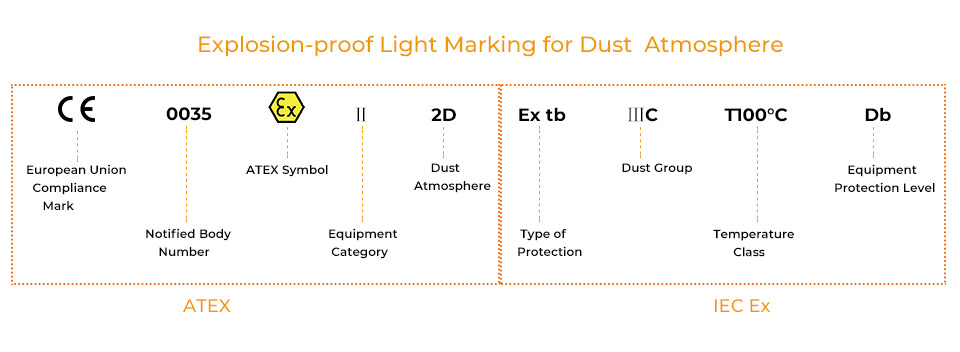

Learning the marking of explosion-proof lights can help us understand the protection of lights and apply them to the appropriate hazardous locations.

Here are pictures of the explanation of equipment marking for explosion-proof light in gas and dust atmospheres.

Right Explosion-proof Lights for Hazardous Areas

So far, we have known the classification of hazardous areas and explosion-proof lighting fixtures. It is time to select the lights that are applicable for hazardous areas.

Here is a table of references to the different hazardous locations and the required safety level of the equipment.

AGC provides HA04 Sparkle as the explosion-proof lighting solution.

Sparkle is an LED flood lighting designed for hazardous locations. It is designed with safety and reliability at the forefront in order to meet and exceed customer expectations. Equipped with stainless steel hardware and DACROMET coating with multiple protective layers as well as a low copper aluminum body to ensure resistance to corrosion, harsh chemicals, and tough environments. The Sparkle is approved for use in UL844: Class I Division 2, Class II Division 1; IEC60079: Zone 2, Zone 21, and 22.