If you're looking to upgrade your space with some smart lighting features, installing a microwave or passive infrared (PIR) motion sensor is a great place to start. These devices can automatically turn lights on and off based on motion detection, saving you energy and adding convenience. But you might be confused about the difference between a microwave and a PIR sensor, as well as how to maximize the effectiveness of both.

In this blog post, we will explain these two types of sensors, how they work, and provide tips to maximize their potential and reap the benefits they offer. So let's get started - here's everything you need to know to put your microwave or PIR sensor to work!

What is a microwave sensor?

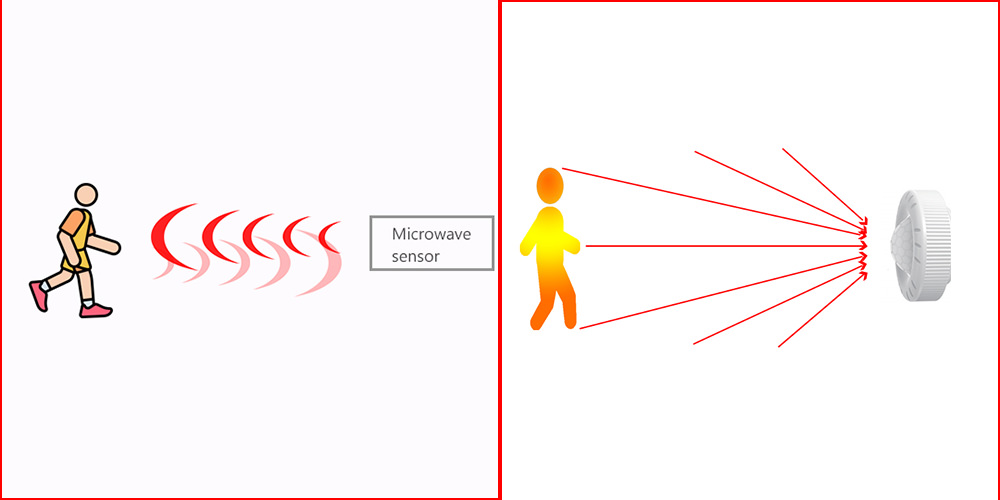

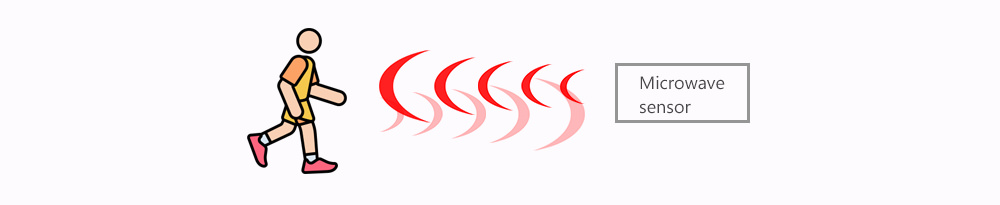

A microwave sensor is a motion detection device that uses microwaves to sense movement in a room. It works by continuously sending out microwave signals and measuring the reflections of objects and people within its detection zone. When a person moves through the area, the sensor detects a shift in the received microwave pattern and triggers the lights to turn on.

How does a microwave sensor work

A microwave sensor consists of two main components: a transmitter and a receiver. The transmitter emits a continuous wave of microwave radiation, which has a wavelength between 1 mm and 1 m and a frequency between 0.3 and 40 GHz. The receiver detects the reflected wave that bounces off any object within the sensor's range.

The microwave sensor operates based on the Doppler effect, which is the change in frequency of a wave when either the source or the observer is in motion. When an object is stationary, the frequency of the reflected wave matches the frequency of the emitted wave. However, when an object is moving, the frequency of the reflected wave changes by the object's speed and direction. The receiver can measure this frequency shift and calculate the object's velocity and distance.

Microwave sensors offer numerous advantages over other types of motion sensors, such as infrared or ultrasonic sensors. They can function in any weather condition, day or night, and are unaffected by dust, smoke, or fog. Additionally, they can penetrate certain materials like glass, wood, or plastic, and cover a large area with a single sensor.

However, microwave sensors also have some drawbacks, including high power consumption, susceptibility to interference from other sources of microwave radiation, and the potential for false alarms triggered by small or fast-moving objects. Therefore, it is crucial to select the appropriate microwave sensor for your lighting system and install it correctly.

Tips to use microwave sensors effectively

Microwave sensors are excellent devices for motion detection and controlling your lighting system. However, there are some important considerations to keep in mind when using them.

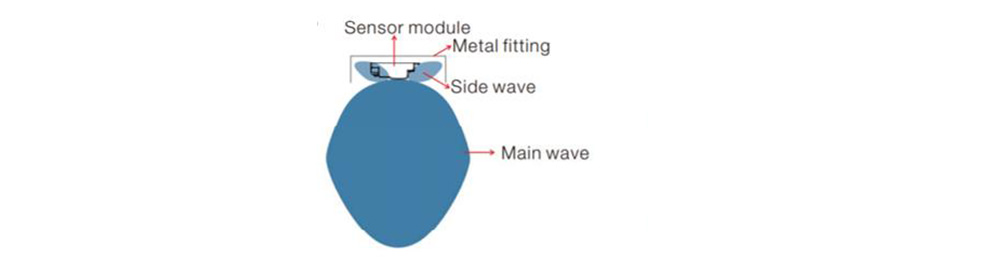

Microwave detection consists of two parts: the main wave and the side wave. The main wave is responsible for detecting motion signals, while the side wave does not affect the motion detection process but can potentially disrupt the main wave if the microwave motion sensor is integrated into a sealed metal luminaire. This is because microwaves are unable to pass through metal.

In cases where the microwave module is incorporated into a metal lighting luminaire or positioned near a wall, the side wave gets reflected by the metal base or the wall. This reflection can interfere with the main wave, resulting in suboptimal performance of the microwave motion sensor. To address such issues, it is beneficial to either reduce the detection sensitivity or mitigate the impact of the side wave.

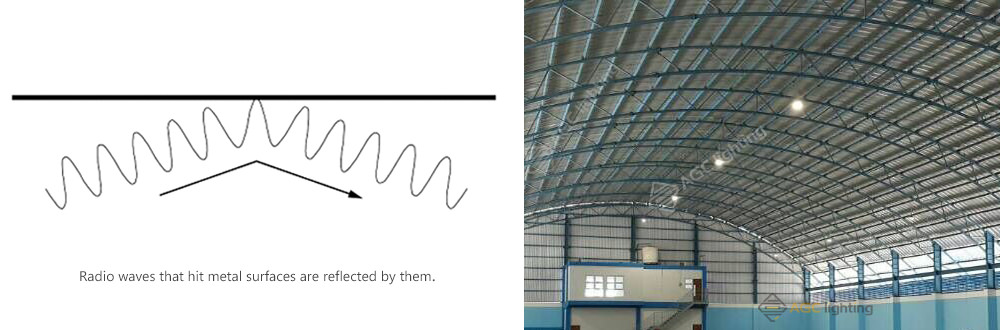

Microwave sensors utilize microwave radiation, which is an electromagnetic wave capable of penetrating certain materials such as glass, wood, or plastic. Therefore, it is essential to be cautious about where you install them and avoid placing them near metal objects like pipes, wires, or appliances that can obstruct or reflect the microwave signals.

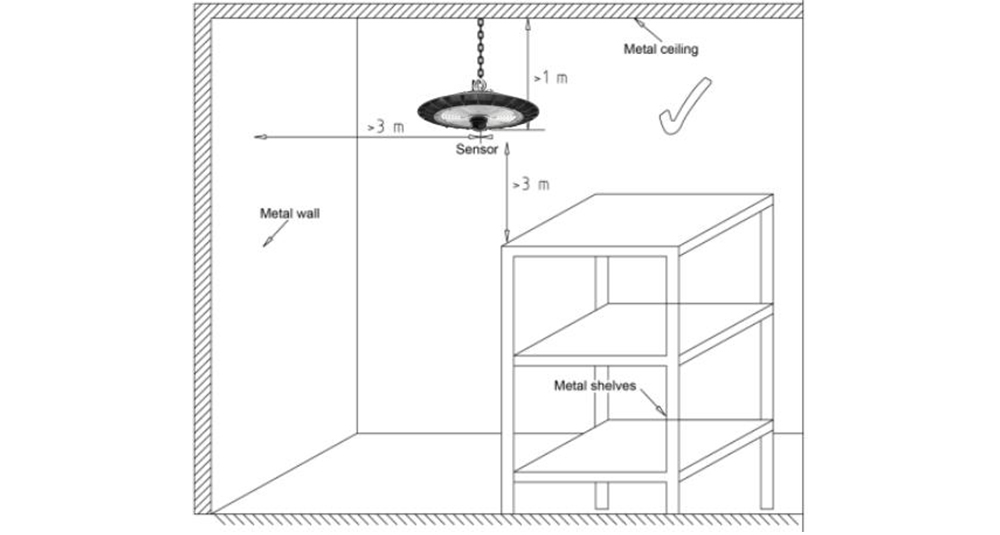

In cases where a warehouse utilizes metal sheets for the roof or walls, the microwaves can be reflected multiple times, causing interference. Additionally, metal sheets are typically thin and susceptible to slight shaking due to wind, rain, or other vibrations, which can pose a safety risk. We strongly recommend installing the lamp at a distance of 1-3 meters away from the metal, as shown below:

Of course, we also have additional details regarding the application of microwave sensors apart from the above-mentioned notices. Please carefully read the application notice for microwave sensors:

- The sensitivity area is influenced by factors such as the speed and size of moving objects, mounting height, mounting angle, working environment, and reflecting materials. The provided detecting area is a typical value measured by 165cm/65kg testers in an indoor open environment.

- Daylight thresholds are measured on a sunny day without shadows, considering ambient light and diffuse reflection. Different environments and climates may result in varying brightness values measured by the daylight sensor.

- Sensor parameters may require reconfiguration in different installation environments. Please refer to the following instructions or contact the manufacturer for assistance.

- The sensor is designed for indoor use only. Its waterproofing effectiveness will be compromised in outdoor or partially outdoor settings. False triggering may occur due to wind, rain, or moving objects.

- The installation height of the sensor product should not exceed 15 meters, with the optimal height being 12 meters. The distance between two sensors should be greater than 3 meters.

- When the sensor is installed in a metal lamp, on a metal reflective surface, or in a small enclosed environment, the microwave signals may be reflected multiple times, resulting in false triggering. Please reduce the sensor's sensitivity or consult the manufacturer for technical support.

- Vibrations will be interpreted as motion signals by the sensor. Therefore, it is important to install the sensor away from objects that vibrate for an extended period, such as large metal equipment, pipes, air conditioning outlets, exhaust vents, smoke exhaust machine ports, or shaking fans.

- Microwaves cannot penetrate metal. Avoid placing the product inside a closed or partially closed metal lamp. Neither metal nor glass should be used to cover the product.

- For new installation environments, it is recommended to initially install and test 5 prototype units before proceeding with bulk installation.

What is a PIR sensor?

A PIR sensor is an electronic device that utilizes infrared radiation to detect the presence of moving objects within its range. It operates on the principle of passive detection, which means it does not emit any signals but instead responds to changes in the infrared energy emitted by objects.

How does a PIR sensor work

A PIR sensor is composed of two main components: a pyroelectric sensor and a lens. The pyroelectric sensor is a material that generates a small electric charge when exposed to heat. The lens is responsible for focusing the infrared radiation onto the sensor and defining the detection area. The PIR sensor compares the infrared radiation difference between the background and a moving object, triggering an output signal when a significant change is detected.

The sensor incorporates circuitry to amplify and process these signals, specifically filtering out random disturbances and targeting human motion. When the predefined motion signature is detected, the PIR sensor promptly sends an activation signal to the lighting system, turning on the lights. The sensor continuously monitors infrared level changes to keep the lights on while occupancy is detected.

However, PIR sensors do have certain limitations. They can be sensitive to ambient temperature, susceptible to interference from sunlight or other infrared sources, and unable to detect stationary objects.

Tips to use PIR sensors effectively

To maximize their effectiveness and ensure safety, it is crucial to understand how to use PIR sensors properly.

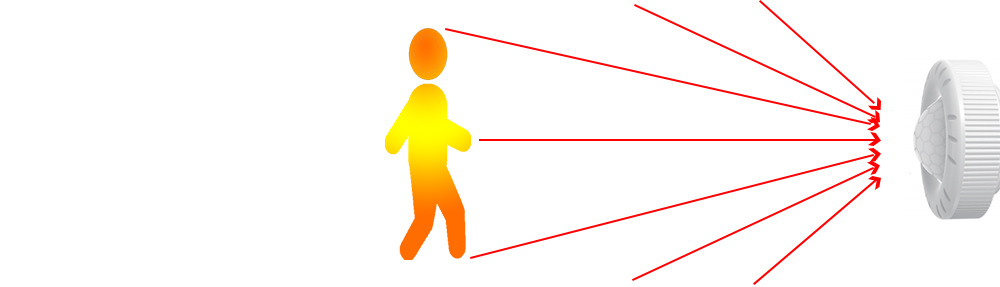

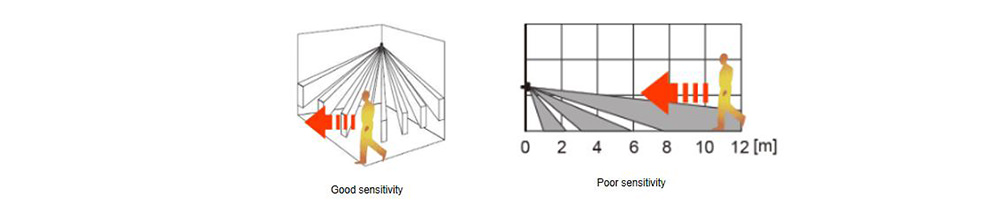

The pyroelectric infrared sensor is least sensitive to radial movement and most sensitive to tangential movement (that is, the direction perpendicular to the radius).

When conducting distance tests, it is recommended to perform them in a nighttime environment with an ambient temperature of 25-30℃, humidity ranging from 50-70%, and the human body surface temperature at 36-37℃. The person walking should maintain a speed of 0.6m/s to 1.5m/s in the cross-cutting direction. The maximum induction angle of the product is achieved when it is set at the highest sensitivity during the test. If set at low sensitivity, the maximum induction angle may not be achievable.

Here are some tips to help you harness the full potential of PIR sensors in your lighting setups:

- Avoid installing PIR sensors outdoors to prevent false triggering caused by ambient temperature changes. Also, avoid placing them in positions sensitive to temperature or airflow changes to prevent sensor failure or high-temperature issues.

- Keep PIR sensors away from air conditioners, refrigerators, exhaust vents, furnaces, and other areas with fluctuating air temperatures.

- Ensure that screens, furniture, large bonsai plants, or any other barriers do not obstruct the detection range of the PIR sensor.

- There should be no reflective objects in front of the PIR sensor, as reflected light can cause incorrect triggering.

- When installing PIR sensors indoors, avoid directly facing them toward windows. This will help prevent false alarms caused by hot air disturbances or movement outside the window. The direction of movement also influences the sensitivity of the infrared pyroelectric sensor to human body movement.

- Keep PIR sensors away from electromagnetic wave-emitting devices such as Wi-Fi routers or cameras. Maintain a distance of more than 2 meters to prevent electromagnetic interference.

- Due to the relative fragility of the infrared probe on the PIR sensor, it is important to handle it with care during production, storage, transportation, and installation. If the product is not effectively protected with proper packaging, it should be handled gently. Dropping the product may result in hidden cracks in the infrared probe or damage to internal chips, leading to a loss of detection or even spontaneous malfunction.

Differences between microwave and PIR sensors

Here's a table highlighting the key differences between microwave sensors and PIR (Passive Infrared) sensors:

|

|

Microwave Sensors |

PIR Sensors |

|

Technology |

Emit microwaves and measure the reflected signals |

Detect infrared radiation emitted by objects |

|

Detection Principle |

Doppler effect: detects changes in frequency caused by moving objects |

Changes in infrared radiation levels caused by the movement of warm objects |

|

Sensing Range |

Longer, can penetrate walls and other materials |

Shorter, requires line-of-sight |

|

Coverage Area |

Wide-angle coverage, suitable for large areas |

Narrower coverage area, better for smaller spaces |

|

Sensitivity to Movement |

Detects both small and large movements |

Primarily detects the human body (hot source). |

|

False Triggering |

More prone to false triggering due to sensitivity to environmental factors like wind or rain |

Less prone to false triggering as they rely on heat signatures |

|

Application |

Ideal for large spaces, outdoor areas, |

Ideal for smaller spaces, indoor areas, |

|

Power Consumption |

Higher power consumption 0.8~1.4W, compared to PIR sensors |

Lower power consumption by 0.5~1W, making them more energy-efficient. |

With proper placement, environmental considerations, and regular maintenance, you can significantly minimize false alarms for your microwave and PIR motion sensors. By implementing these simple tips, you'll enhance the reliability and efficiency of your lighting system, ensuring it operates smoothly while providing the security and convenience you desire.

Remember, our team of lighting experts is always ready to assist you with any questions or concerns you may have about your lighting projects. Don't hesitate to contact us for reliable lighting solutions that meet your unique requirements.