Street lighting is crucial for improving nighttime visibility, reducing accidents, and ensuring public safety. With the rise of LED technology, streets are now illuminated with bright and efficient white light. However, starting in early 2021, many cities and towns in the U.S. and parts of Canada began noticing a strange phenomenon: some street lights were emitting a purple glow.

This unexpected purple hue has raised concerns about its impact on driver and pedestrian safety, as it alters the way people perceive their surroundings at night.

There is a clear explanation now: LED phosphor degradation. While most reports point to this as the primary cause, what exactly does it mean? Is purple light harmful? Will it happen more frequently? More importantly, how can you avoid this issue in your own street lighting projects?

What’s causing street lights to turn purple?

In many reported cases, it's the degradation of the LED phosphor that causes street lights to turn purple. To understand it, let’s learn how LED street lights emit white light first.

How do LED street lights emit white light?

LEDs (Light Emitting Diodes) are semiconductor devices that emit light when an electric current is passed through them. While LEDs can emit light of various colors, they do not produce light naturally.

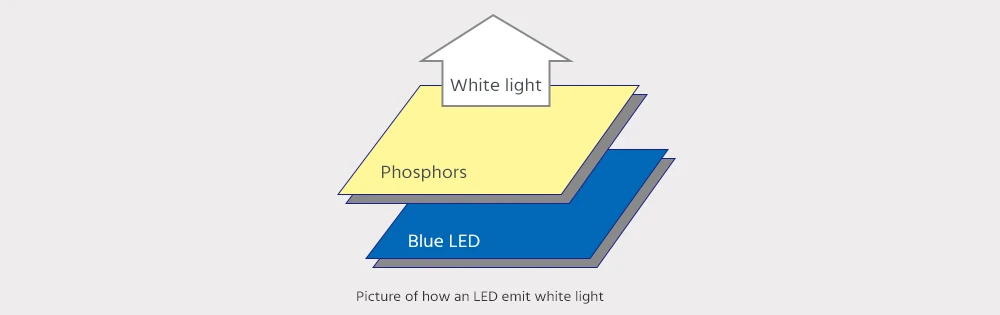

The core of the LED street light is a blue LED chip. This blue chip is coated with a layer of yellow silicone phosphor. When the blue light from the LED chip excites the phosphor coating, the phosphor emits yellow light. With the combination of the original blue light and the emitted yellow light, the light appears white to the human eye.

By adjusting the composition and thickness of the phosphor layer, manufacturers can produce different shades of white light, from warm to cool white.

LED phosphor degradation causes street lights to turn purple

When the phosphor coating on a street light degrades over time, the light can appear purple or blue. This degradation can lead to cracks, adhesion issues between the LED chip and the silicone-phosphor layer, or even complete delamination. Without the phosphor coating, the LEDs emit blue or purple light instead of white light.

So, what causes the silicone-phosphor layer to degrade?

It is mainly caused by faulty or poorly manufactured phosphor coatings. Several factors also contribute to this. One common cause is the buildup of heat inside the lamp due to constant operation. Repeated vibrations from passing vehicles can also play a role, as well as the simple effect of gravity gradually pulling down on the light fixture over time.

Are purple street lights harmful?

The unusual purple streetlights have raised concerns, with some people worrying that the color might pose health risks, such as eye strain or mental health issues. However, there is no scientific evidence to support these claims, and the human eye is quite adaptable to different light colors.

That said, purple streetlights can create safety concerns. The distinct hue may reduce the overall effectiveness of street lighting, potentially impacting visibility for both drivers and pedestrians. This could lead to an increased risk of accidents, particularly in areas with heavy traffic or significant pedestrian activity. Additionally, the unfamiliar color might make some people feel unsafe, even if the lighting levels are technically adequate.

Will purple street lights happen more frequently?

In the short term, you may notice an increase in purple street lights, but over the long term, they should become rare. Many U.S. cities and towns began switching to LED street lights about 16 years ago, with most white LEDs manufactured using similar phosphor-coating techniques. The purple light is likely due to faulty or poorly manufactured phosphor coatings.

Street lights are not purchased individually; instead, governments typically award contracts to companies through large-scale bids. The winning company is responsible for producing all the street lights for a given project, which is why clusters of purple street lights can be found in certain areas during specific periods.

While some purple LED street lights have already been replaced, more may appear in the near future. However, many municipalities and manufacturers are already aware of the problem and are taking steps to replace the defective lights and improve quality control measures. As a result, the frequency of purple street lights should decrease over time as these measures are implemented.

Solutions

The appearance of purple street lights is often caused by LED phosphor degradation, which can be avoided by using high-quality, reliable LEDs. This is crucial for LED lighting manufacturers. To ensure quality, the LM-80 standard should be strictly followed.

LM-80, developed by the IESNA (Illuminating Engineering Society of North America), is a lumen maintenance test method that measures the lumen maintenance, chromaticity, and failure rates of LED packages, arrays, or modules driven by an auxiliary driver. The test lasts a minimum of 6,000 hours, with data collected at 1,000-hour intervals. By adhering to LM-80 guidelines, manufacturers can more accurately predict the lifespan and color consistency of LEDs, reducing the risk of premature failure.

However, since LM-80 applies only to LED components, not entire lamps or fixtures, an LM-79-compliant photometric test report is more useful to you when evaluating the performance of complete LED lighting products.

As an LED lighting manufacturer, AGC understands the importance of delivering reliable, long-lasting products to help our customers win bids and reduce maintenance costs. We strictly adhere to relevant standards to ensure quality and performance. Contact us to learn more about how we can support your projects.