If you've ever looked for lighting fixtures for high temperature applications, you know that not all high bay lights are suitable for the application. Most high bays light on the market can only work at a maximum temperature of 50°C. However, high-temperature applications such as smelters, concrete sheds, and waste disposal plants operate at temperatures in excess of 60°C, and some can even reach 70°C.

Who should you turn to for a reliable solution? It’s us.

Here are 3 ways for a high bay light to meet the high temperature requirements.

1. Optimize the driver design

With the driver stand on the heat sink, the highbay can easily transfer to heat out through airflow.

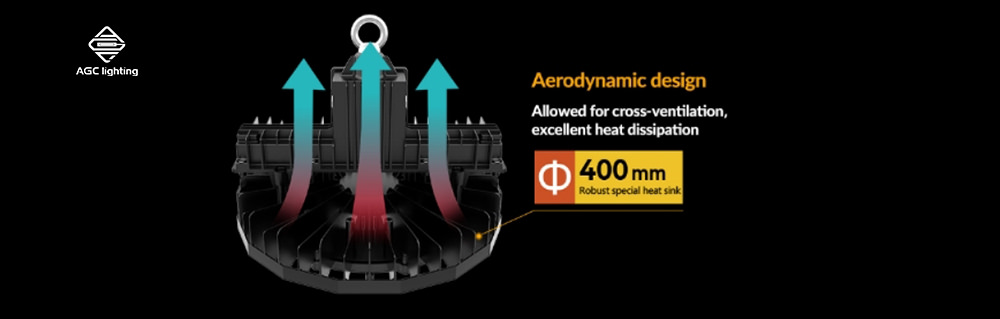

2. Expand the heat dissipation area

A bigger heatsink with less power consumption can always help cool down the highbay for a longer lifespan.

3. Adopt aluminum with higher thermal conductivity

Besides die-cast aluminum, there is cold-forging aluminum that can dissipate heat 3 times faster and is often used on industrial lighting products. In addition, light weight and small size are another 2 characteristics for cold-forging aluminum.

We offer a range of standard products for the solutions mentioned above. If you are interested in any of these products, please feel free to contact me for more information. I would be happy to provide you with all the details you need to make an informed decision.