ATEX certification ensures lighting is safe for explosive environments. This article explains the different equipment groups you'll encounter on ATEX labels.

ATEX Lighting Equipment Groups

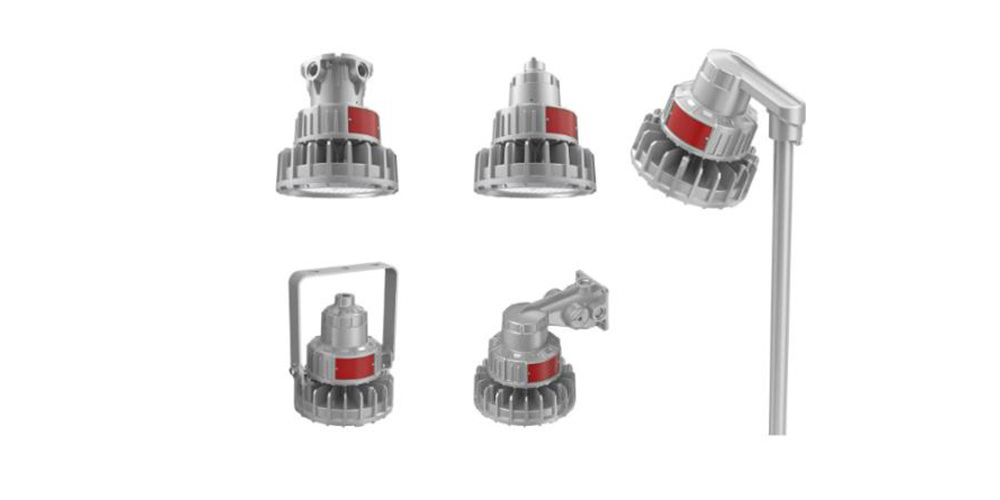

Here, we show you the one for the HA03 light from AGC:

Example Label:

ATEX: II 2G Ex d IIC T6/T5 Gb, II 2D Ex tb III C T80℃/T95℃ Db IP66

The confusing part is often the "II" and "IIC/IID" codes.

Here's a breakdown to help:

Equipment Groups:

- Group I: Designed for mines with methane gas (firedamp).

- Group II: For explosive areas excluding mines.

- Group III: For areas with dust explosion hazards (excluding mines).

Subgroups within Groups:

Group II (Gas):

- IIA: Suitable for areas with a lower gas explosion risk (like propane).

- IIB: Suitable for areas with moderate gas explosion risk (like ethylene).

- IIC: Suitable for areas with the highest gas explosion risk (like hydrogen or acetylene).

Group III (Dust):

- IIIA: Suitable for areas with combustible lint dust.

- IIIB: Suitable for areas with non-conductive dust.

- IIIC: Suitable for areas with conductive dust.

Compatibility Rules

More versatile equipment can be used in more zones. Equipment rated for IIC can be used in IIC, IIB, and IIA zones. Equipment rated for IIB can be used in IIB and IIA zones. Equipment rated for IIA can only be used in IIA zones (not higher-risk zones).

Similar rules apply to dust explosion zones. Equipment rated for IIIC can be used in all three dust zones (IIIC, IIIB, IIIA).

What this means for you

These rules ensure the lighting is safe for the specific explosion risk in hazardous areas. By understanding equipment groups, you can choose the right light for your safety needs.

For example, the HA03 light can be used in all gas and dust zones (IIA, IIB, IIC, IIIA, IIIB, IIIC).

Do you have any questions regarding this article? Or do you have any other questions about the ATEX lighting? Please feel free to contact us.