When we talk about industrial lighting, What are we talking about?

Today I am gonna discuss a more important sector in industrial lighting - Explosion Proof Lighting.

Working with the wrong kind of lighting can be just as dangerous as working with no lighting at all. If you work in an explosive atmosphere then you can easily be putting yourself in danger if you use the wrong kind of light. Consequently, It is important to have a source of light that you can rely on and be confident in its abilities.

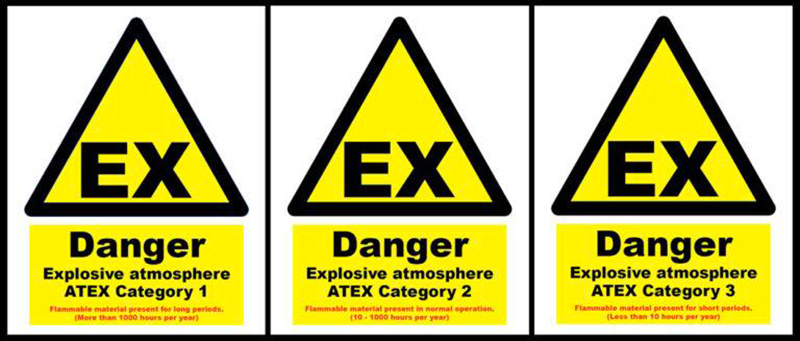

We always mentioned one concept when we talked about Explosion Proof Lighting - ATEX

So the question is coming:

What is ATEX lighting?

ATEX is “ATmosphere Explosive”

ATEX is the name commonly given to the two European Directives for controlling explosive atmospheres.

The ATEX Zones for lighting products are designed in either Zone 1 or Zone 2 depending on the exposure threat to flammable gases or vapor --- accordingly, these hazardous area lighting systems must be correctly specified according to the level of explosion, Classifying hazardous areas into Zones.

Zone 1: is a hazardous area classified by ATEX in which an explosive atmosphere consisting of a mixture air of flammable substances in the form of gas, vapor or mist is likely to occur in normal operation occasionally.

Zone 2: is a hazardous area classified by ATEX in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapor or mist is not likely to occur in normal operation but, if it does occur, persists for a short period only.

What are the benefits of HA05 explosion proof light?

AGC always cares about explosion proof lighting and designed the latest HA05 LED Luminaries for Hazardous Locations

You must wonder what are benefits of HA05 explosion proof light?

Firstly: Multiple mounting options

Which means it can meet your various installations in different ways.

Secondly: the feature of corrosion-resistant

Adopt high-strength low-copper aluminum alloy die-casting shell, surface spraying special outdoor powder, standard parts and brackets are made of stainless steel+special anti-corrosion treatment.

That means you can not only use it in explosion-proof locations but also in some occasions where anti-corrosion is required.

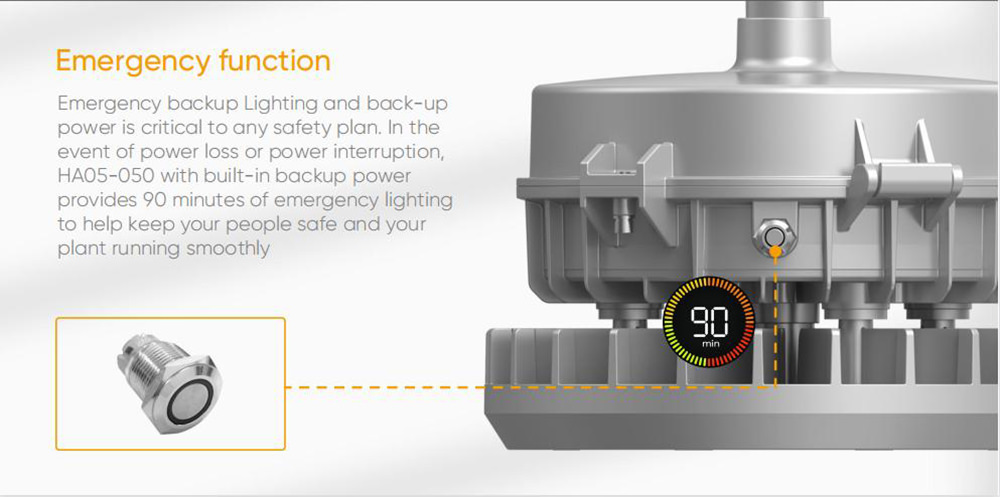

Last but not least: the emergency function

HA05-050 with built-in backup power provides 90 minutes of emergency lighting to help keep your people safe and your plant running smoothly.

There are so many details to wait for you to explore more for explosion proof lighting.

Contact us if you have a plan for ATEX Lighting in the future.