As known, the harsh outdoor environment threatens the stable performance of lighting fixtures. Outdoors LED lighting fixtures, like street lights and flood lights, are long-term exposed in the outdoors. It will take different natural environments, such as rain, ice-snow, wind, sunshine, etc, so we have to consider the sealing, waterproof, and dust-proof, except the structural strength, heat resistance, and anti-aging properties while designing the LED fixture structure. There is an important factor that can improve the protection of LED fixtures and withstand harsh outdoor environments, but it is often overlooked, the vent.

Why do outdoor LED lighting fixtures need vents? How does the vent work? Is there any outdoor lighting solution with vents?

Just follow the post, and find the answer.

Reasons for adding a vent to outdoor LED lighting fixture

In simple words, the addition of vents contributes to more reliable LED luminaires.

Adding vents to outdoor LED fixtures because vents can prevent moisture from damaging the electronics and prevent fogging of lenses.

Prevent moisture from damaging electronics

The operating principle of LED fixtures is converting electric energy into light energy and heat energy, heat generation will raise the temperature of LED fixtures, but it’s the electrical appliance can’t contact any water, such as the LED chips and wiring, LED driver, etc. So the inside and outside to be completely isolated for good waterproof sealing.

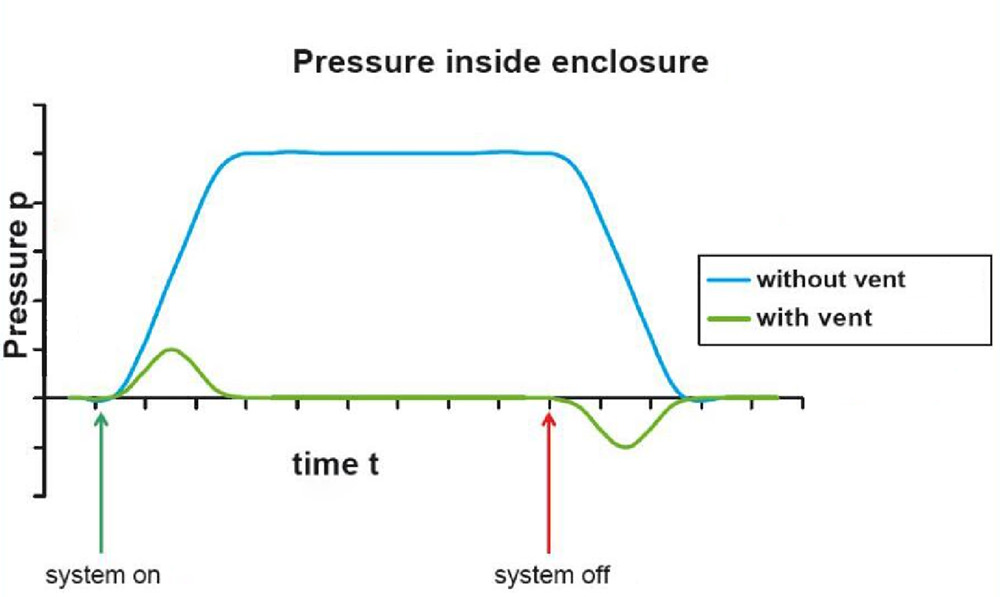

If so the internal and external air of LED fixtures can’t be interchangeable, meanwhile, the thermal transmission of air is very very poor, once the LED fixture starts to work, the internal temperature will be higher than the external temperature. The expanding coefficient of air becomes higher by 10% with the 30℃temperature rise, their pressure between inside and outside will be higher by 10%,

In order to maintain the IP protection level of the factory, avoid the occurrence of negative pressure water absorption caused by the aging of the rubber strip under the action of internal and external stresses after the period.

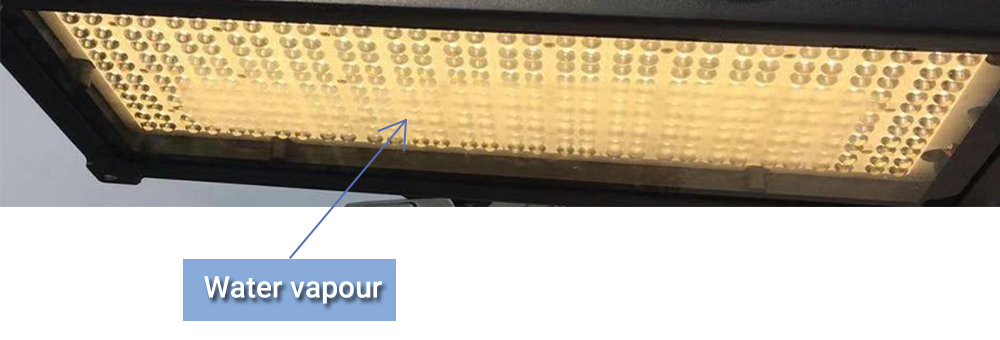

prevent fogging of lenses

In addition, the lamp is not a vacuum when assembled in the production line, and there will be humidity in the environment. Due to the pressure difference inside and outside the cavity, there will be fog attached to the glass or lamp shell when working (the degree of fog depends on the humidity during assembly). It should be waterproof and also eliminate fog. This is a problem of structure seal (waterproof) and gas exchange.

Except for preventing moisture from damaging the electronics and fogging of lenses, adding vents for LED street lights or flood lights also has the following benefits:

- It can protect sensitive electronic components and products.

- It has a long service life in extreme environments, does not have failure, and is maintenance-free.

- It can greatly reduce electronic and inductance product failure caused by salt corrosion.

- It can greatly reduce fogging and condensation.

- It can reduce casing sealing strip stress through the balance of pressure.

How does the vent work?

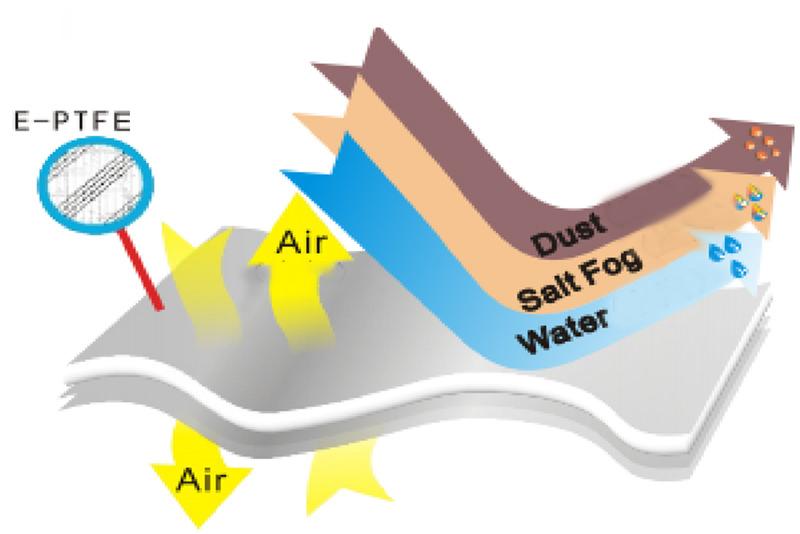

The vent is also called a waterproof breather valve or respirator. It is waterproof and breathable, which means the gas can go through freely when there is differential pressure between the internal and external of LED fixtures. It's like we usually speak breathing, so commonly known as breather valve or respirator.

We could install a VENT on LED fixtures for unicom on the inside and outside. When the internal pressure is higher than the outside, the gas will be externally discharged.

Once the LED fixture is off, the internal pressure is lower than the external pressure, and gas will into the internal, but avoid the water, dust salt fog, so as to achieve the balance between the internal and external pressure and waterproof.

The VENT would solve the problem of the structure sealing and gas exchange perfectly.

|

AGC outdoor lighting solutions with vent

To ensure the high quality and stable performance of our products, we only use good vents with the following features:

1, Dust-proof and waterproof but breathable;

2, Protection from dust, oil, and water intrusion, the IP level up to IP67 and IP69K;

3, Great permeation capacity can balance internal and external pressure and the integrity of the casing seal;

4, Resistant to chemicals, resistance to acid and alkali, detergent-resistant, aging resistance, and temperature extremes. Enhance product reliability in harsh environments;

5, Reduce fogging, and condensation, eliminate moisture, and improve the lifetime of the products.

Of course, if there are corrosive gases in the environment, like HCI gas (chlorhydric acid), ammonia gas, or explosive gases, we don’t suggest the VENT for LED explosive-proof light.

Here are some examples of our products with the vent. We also take the aesthetic and function into account.

1, ST10 street light, under the lamp, avoid the sunshine for a better lifetime.

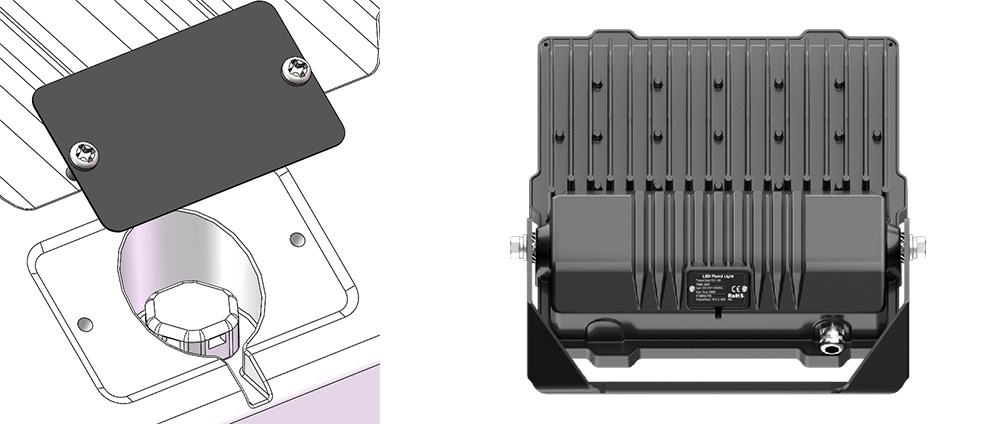

2, Flood light design, the VENT is concealed under the nameplate: