LED lighting fixtures have been widely used in many fields because of its energy-saving and long lifespan features . As a new type of luminaires , it has become optimal replacement of traditional lights. many projects of replacing outdated lighting fixtures have been conducted all over the world and have become a rising tendency.

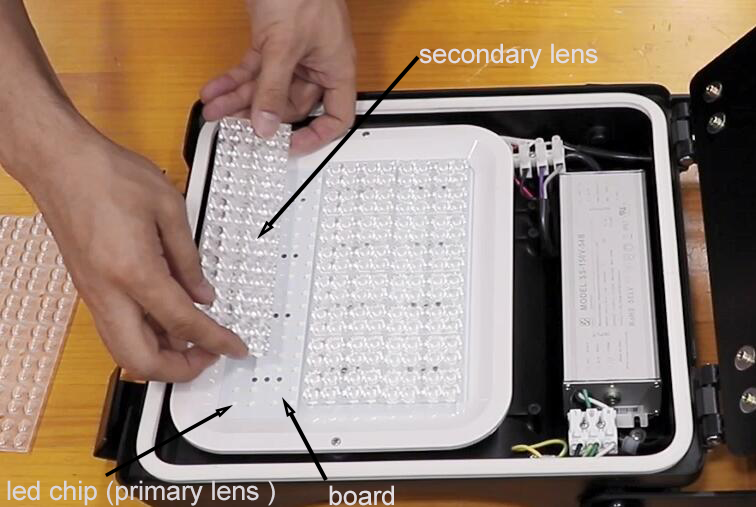

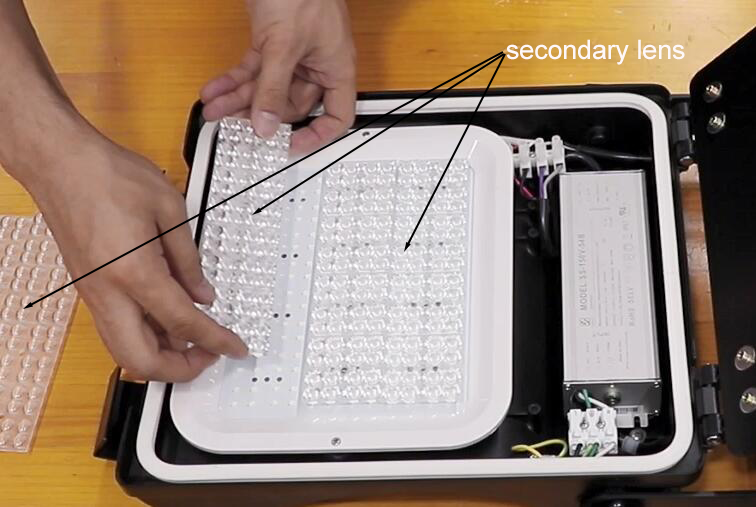

before explain why led flood light need secondary lens . we think it is necessary to have a probable understanding of the strecture of light fixture especial know the position of board , LED chip and secondary lens .now let's take the structure of flood light as example .

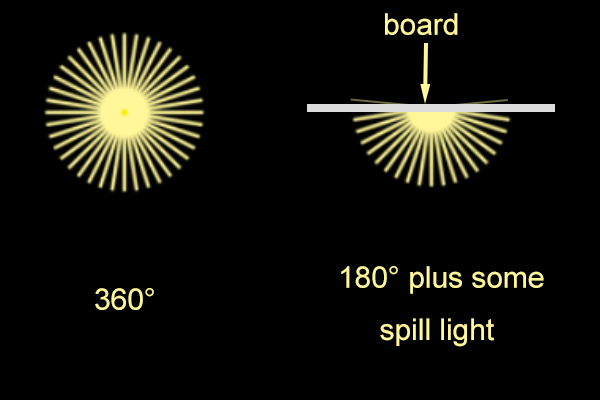

The LED chip theoretically can illuminate 360° in a three-dimentional space, but actually the chip is fixed on the board and encapsulated in the LED housing structure so that led lights maximally offer only 180° beam angle in ideal state.certainly there may be some spilled lighting that beyond the scope of 180 °.

In general ,there is a elementary lens on the top of led chip. through this lens , all light can be effectively gathered together and then obtains some basic optical angles such as 180°,150°, 120°, 90° ,60° and so on. However, these fundamental beam angles are far from meeting the diverse requirements of market today. after selecting of LED chip, we have been able to foresee the illuminating area because of their relatively fixed beam angles. it is likely that the existing distribution angles are not what actual project want . illuminating engineering planners all want to get optimal lighting scheme rather than comsume more energy to light up the point where lighting isn't required, leading to waste of power. led lighting mamufacturers should spare no effort to design more pratical angles . secondary lens is the most popular method at present. Therefore, In order to increase the light distribution angles . we can add a secondary light distribution lens to LED lighting system to reach the requirements of different lighting effects.

some main types of lens's material and their cons and pros

1.silicone

Generally the silicone lens what we talk about here is liquid silicone lens rather than the solid one . beacause solid silicone is hard to process and the processing technology is unripe and to be improved , what used most nowadays is liquid silicone . its high temperature resistance feature allow it to stand reflow oven temp,about between 150℃~225℃. so it is commonly used to encapsulate on led chips .in general, silicone lens is small in size and 3-10mm in diameter . if bigger size wanted . silicone material no longer suits for using.There will exist some problems in fastening and processing.

2.polycarbonate (PC)

it has advantage of high productivity and high light transmittance and the tolerance temparature is up to 110℃ . if surpassing this temparature , it is possible to make lens out of shape .

3.Polymethylmethacrylate(PMMA)

PMMA is familiar material in industry field . in terms of PMMA lens. the lighting transmittance is 93% when the lens's thickness is 3mm .the lighting transmittance , so to speak , is high. and it also can meet the requirement of mass production. all these are praiseworthy except it tolerance temparature is lowest among these four materials , only 80 ℃.

4. glass

glass has the characteristics of high light transmittance, high temperature resistance, corrosion resistance and saline-alkali tolerance. but it isn't ideal material for making led lens at present . compared with other materials, glass is heavier in the weight and it is difficult to bend and easy to break up .this could result in difficulties to make shape of led lens and batch production. it is not good for reduce the weight of led lighting fixture if using glass lens .in addition , its production technology is more complex and the price is relatively higher . so glass lens isn't customers' preference in the market.

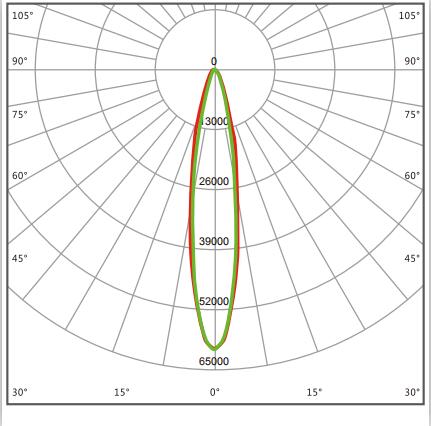

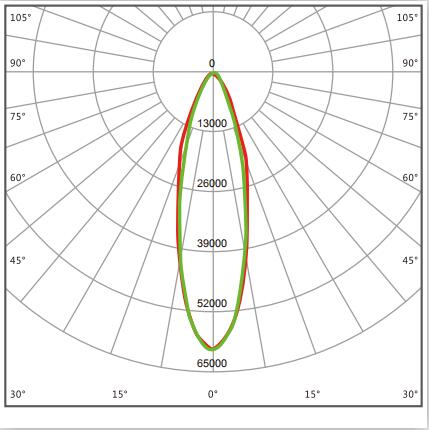

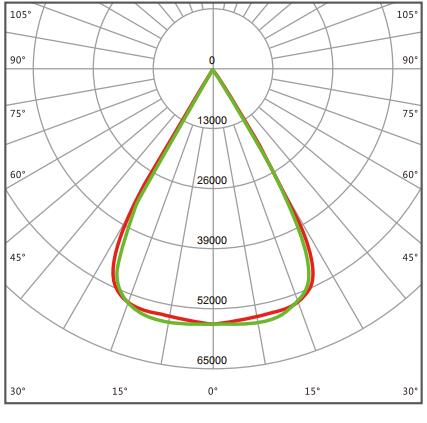

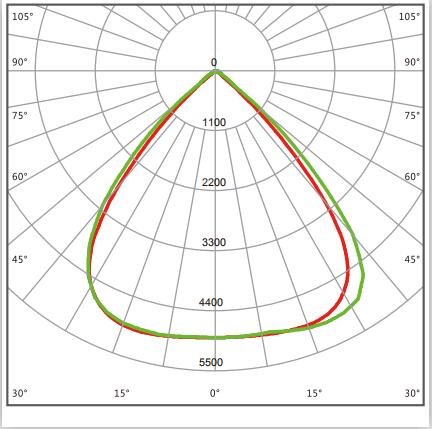

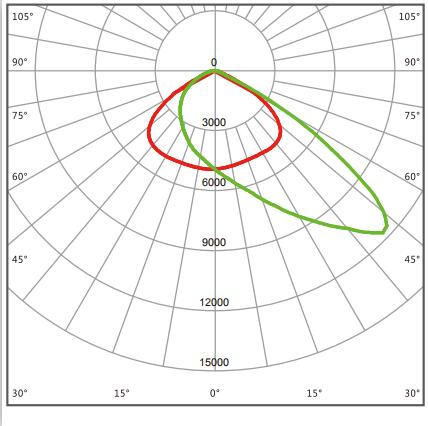

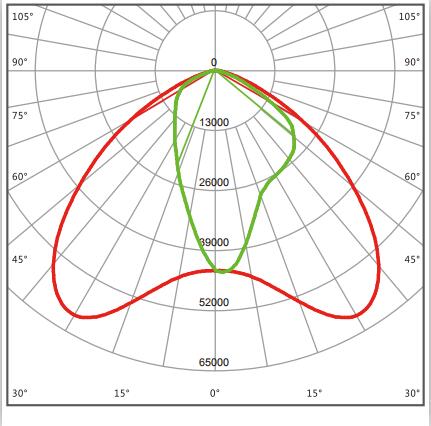

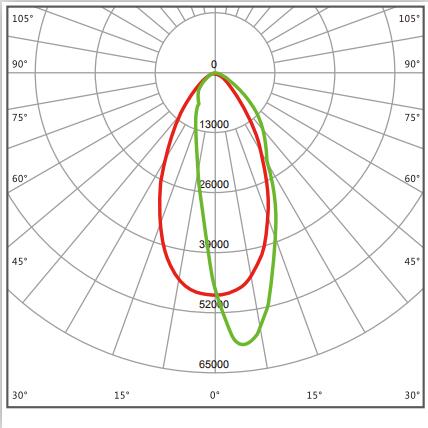

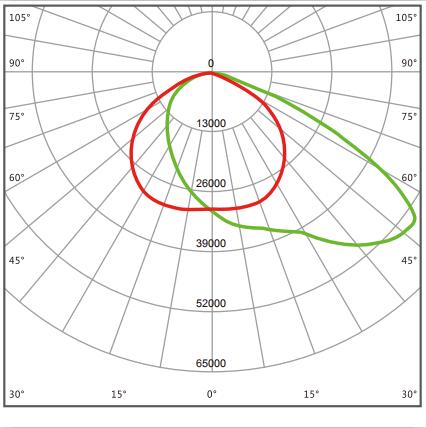

different light spreads of led flood light