Corrosion is a common problem that affects materials reducing their lifespan and potentially causing serious safety hazards. To overcome this issue, Engineers from AGC Lighting have tested various corrosion-resistant solutions for our lighting products.

The lighting fixture is made of Housing, LED Module, and LED Driver components, but the parts related to corrosion resistance mainly the housing, also including the glass cover, brackets, screws, etc.

For the harsh environment, AGC Lighting always considers the Cu-Free Aluminum or special surface treatment solutions for the housing part, and the SUS316 screws can well protect the fixtures, the biggest problem left is the bracket.

|

Solutions |

Advantages |

Disadvantages |

|

SPCC normal surface |

good price |

bad corrosion resistance ability |

|

SUS316 |

Good corrosion resistance ability |

Very expensive |

|

SPCC with Hot-dip galvanizing |

Corrosion resistance ability is good |

The price is high and the surface treatment looks not good |

Is there any good way can provide a nice look with high corrosion resistance ability, and also keep a better price? the Answer is yes.

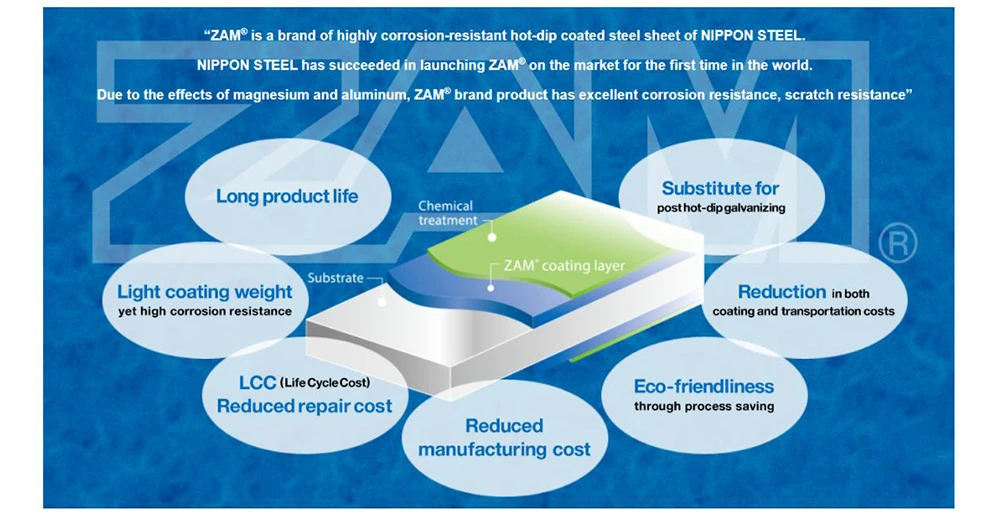

AGC engineer team imported the ZAM material as our bracket, ZAM Coated steel is a technologically advanced hot-dip coated steel, complying with the requirements of Type ZM Coating Class In AS1397:2011, ZAM coated steel allows new installation possibilities in a corrosive environment with potential lower material costs.

ZAM Coating is a blend of Zinc, Aluminum (6%), and magnesium (3%) that provides far greater corrosion resistance than hot-dip galvanized coatings, below are the advantages of the ZAM materials:

| Superior Corrosion resistance | Superior Press formability | Cost reduction through eliminating post hot-dip galvanizing process | ||

| ZAM is 10 to 20 times better than hot-dip zinc-coated steel sheets | With a harder and smoother coating layer than hot-dip zinc-coated steel sheet, ZAM shows excellent press formability contributing to higher productivity. | ZAM enables initial cost reduction through process omission and life cycle cost reduction. |